High mechanical strength foamed ceramic material and preparation method thereof

A foamed ceramics and mechanical strength technology, applied in the field of foamed ceramics materials, can solve problems such as material fracture or fragmentation, and achieve the effects of improving mechanical strength, prolonging service life and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

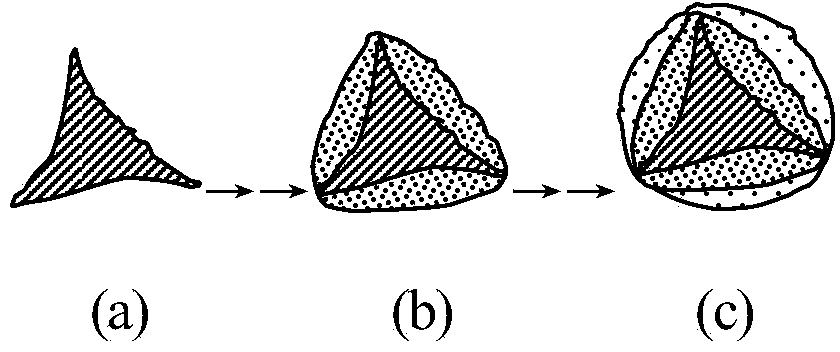

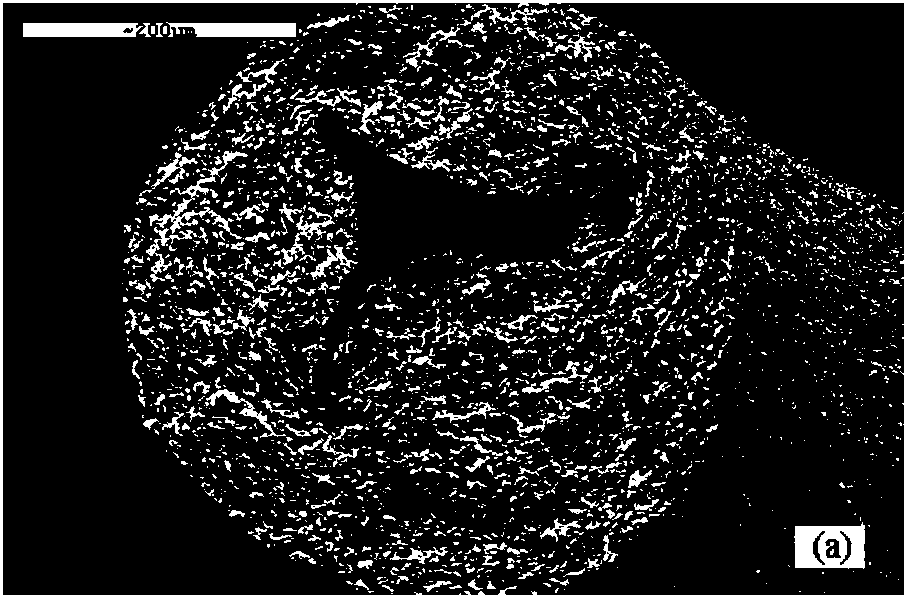

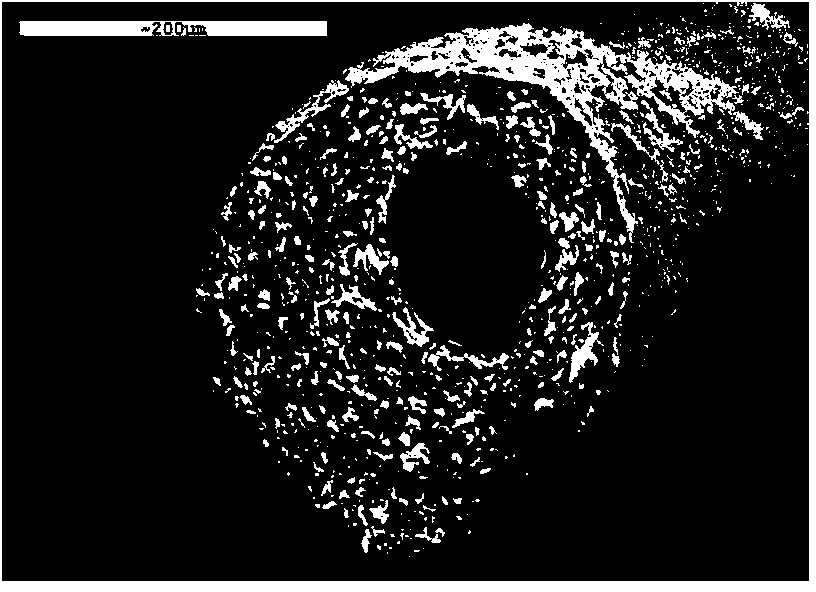

[0028] Such as figure 1 , image 3 As shown, the preparation method of the high mechanical strength ceramic foam material of the present invention prepares an additional coating on the surface of the polymer foam plastic, and modifies the triangular ribs of the polymer foam plastic into a circle or a nearly circular shape. The polymer foam is used as the precursor, and the ceramic foam material is obtained by the replication method. The central hole is circular or nearly circular. Compared with the ceramic foam material with a triangular central hole, the mechanical strength of the material is significantly improved. Specifically Including the following steps:

[0029] (1) dissolving the soluble polymer resin in distilled water or an organic solvent to form a resin solution with a concentration of 10-100 g / L;

[0030] (2) Fully immerse the polymer foam in the above solution to ensure that the resin solution and all areas of the polymer foam are fully infiltrated. If necessar...

Embodiment 1

[0037] The preparation process of the present embodiment to prepare high mechanical strength foamed silicon carbide is as follows:

[0038] 1. Dissolve water-soluble polycarbonate in distilled water to obtain a resin solution with a concentration of 5 g / L;

[0039] 2. Fully soak the polyurethane foam in the above solution, and squeeze the foam repeatedly to ensure that the resin solution is in full contact with all parts of the polyurethane foam. After soaking for 2 minutes, take out the polyurethane foam, and blow off the excess liquid with compressed air;

[0040] 3. Dry the soaked polyurethane foam at 80°C, so that the resin is cured on the surface of the polyurethane foam to obtain a coating, and the triangular ribs of the polyurethane foam are initially rounded;

[0041] 4. Weigh and record data;

[0042] 5. Repeat steps 2 to 4 above until the weight gain of the polyurethane foam reaches twice the weight of the original polyurethane foam;

[0043]6. Using the polyureth...

Embodiment 2

[0047] The difference from Example 1 is that the resin concentration is 10 g / L, and other conditions are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com