Technical method for urea synergistic agent

A kind of synergist and technical technology, applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problems of increased burden on farmers, high volatility of chemical fertilizers, low utilization rate, etc., to reduce pollution, reduce soil bulk density, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

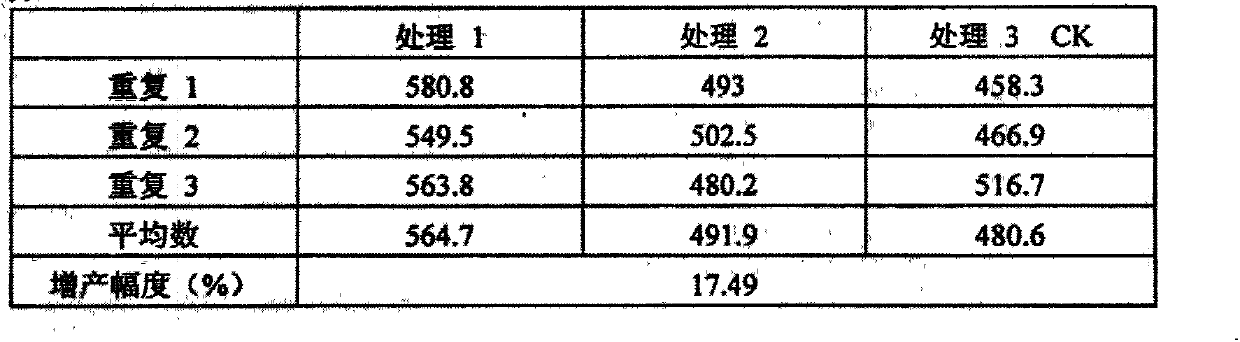

Image

Examples

Embodiment Construction

[0011] A urea synergist technical method is characterized in that it is composed of the following components in terms of mass percentage: diethyl diethyl hexanoate 75%-81%, sodium nitrophenolate 5%-9%, magnesium sulfate monohydrate 4.5%-11%, Zinc sulfate 5.5%-9%, mixed and processed into granules and formed white powdery crystalline substances.

[0012] The production process is as follows:

[0013] a. First heat 81% diethyl aminoethyl hexanoate in the reaction kettle to 120 degrees by electric heater, and keep it warm for 30 minutes through computer control;

[0014] bThen the computer controls the electric heater to cool down to 40 degrees, and adds 9% sodium nitrophenolate and 4.5% magnesium sulfate monohydrate, then raises the temperature to 110 degrees, and then uses the computer to control the electric heater to keep it warm for 3 months Hour;

[0015] c Then lower the temperature to 80 degrees, add 5.5% zinc sulfate and keep it warm for 1 hour, and finally cool to roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com