Method for extracting and separating fucoxanthin from marine unicellular diatom

A technology for separating fucoxanthin and fucoxanthin is applied in the field of extraction and separation of fucoxanthin, and can solve the problems of low yield of pigment extraction, low fucoxanthin content, affecting pigment extraction and the like , to achieve the effect of short extraction time, short time and fast separation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

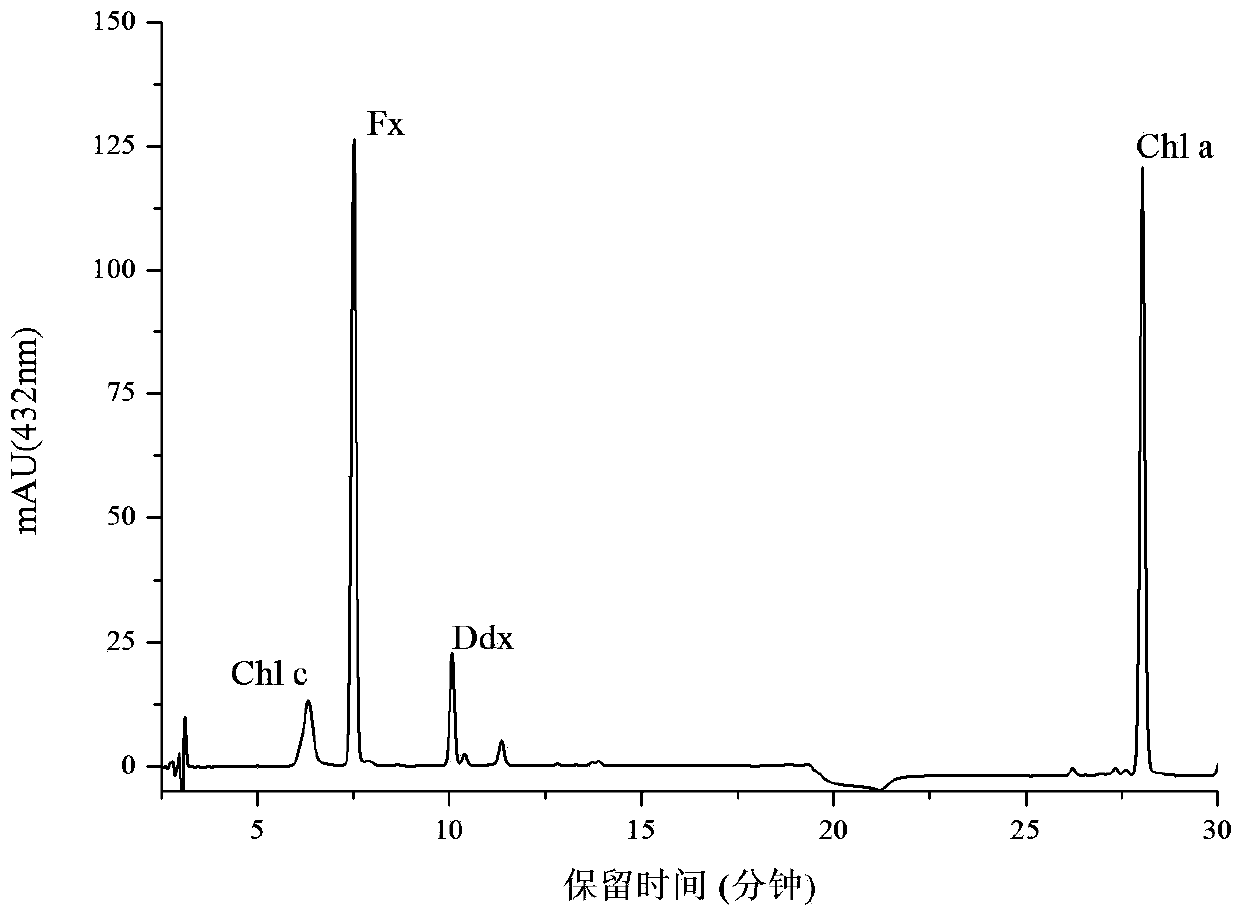

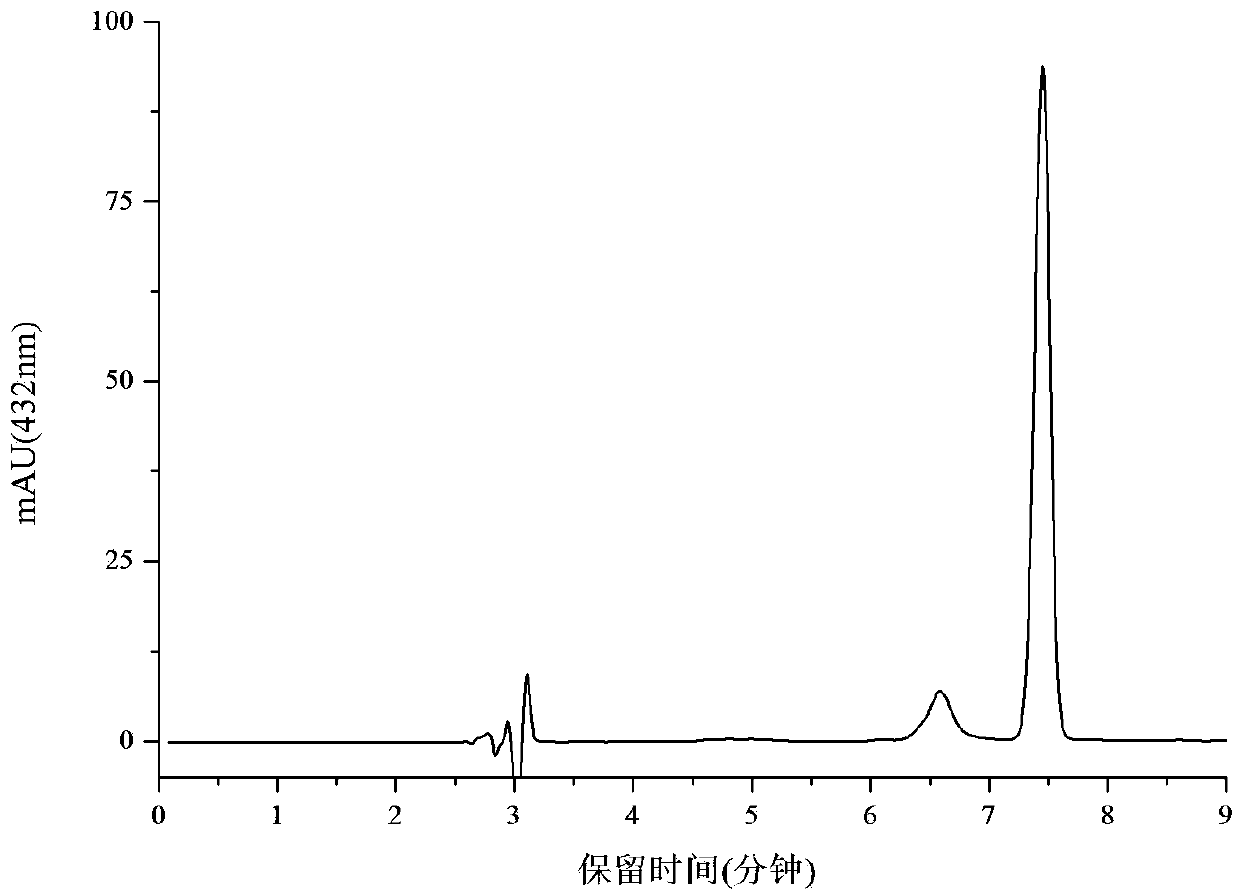

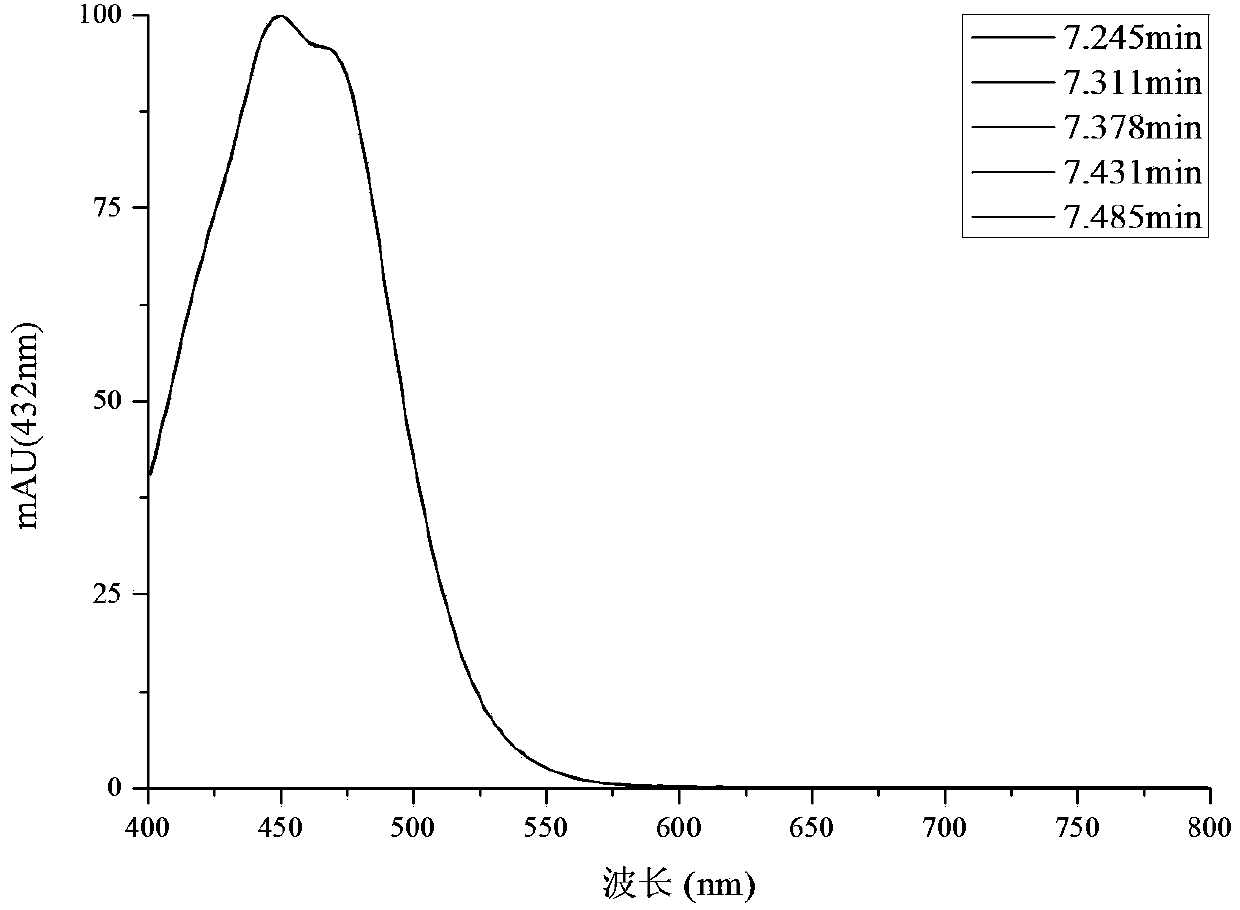

[0031]The above-mentioned cultured Phaeodactylum tricornutum (Phaeodactylum tricornutum) algae liquid was divided into centrifuge tubes, balanced and put into a centrifuge for centrifugation, the centrifugal force was 3000g, and the centrifugation time was 5 minutes. After the centrifugation was completed, the supernatant was removed, and the algal mud in each tube was combined and weighed. According to the ratio of 5ml / g, add pre-cooled (0-10 degrees) mixture of methanol and acetone as the extraction solution (methanol: acetone = 1:1 (V / V)), shake fully to make the algae cells fully contact with the extraction solution, It was then placed in an ice-water bath for 5 minutes in the dark. During the leaching process, fill nitrogen with a ventilation rate of 3-7L / min to prevent oxidation. The supernatant was collected by centrifugation, and the precipitate was extracted once again with the extraction solution at a ratio of 5 ml / g. Centrifuge and collect the supernatant. The pr...

Embodiment 2

[0037] The cultured Phaeodactylum tricornu tum algae liquid was divided into centrifuge tubes, balanced and loaded into a centrifuge for centrifugation with a centrifugal force of 3000g and a centrifugation time of 5 minutes. After the centrifugation was completed, the supernatant was removed, and the algal mud in each tube was combined and weighed.

[0038] According to the ratio of 5ml / g, add pre-cooled (0-10 degrees) mixture of methanol and acetone as the extraction solution (methanol: acetone = 1:1 (V / V)), fully shake, so that the algae cells can fully contact with the extraction solution , and then placed in an ice-water bath for 5 minutes in the dark. Nitrogen was used to prevent oxidation during the extraction process. The supernatant was collected by centrifugation, and the precipitate was extracted once again with the extraction solution at a ratio of 5 ml / g. Centrifuge and collect the supernatant. The extract was filtered through a filter membrane with a pore size...

Embodiment 3

[0046] The cultured Thalassiosira pseudonana algae liquid was divided into centrifuge tubes, balanced and loaded into a centrifuge for centrifugation with a centrifugal force of 3000g and a centrifugation time of 5 minutes. After the centrifugation was completed, the supernatant was removed, and the algal mud in each tube was combined and weighed.

[0047] According to the ratio of 5ml / g, add pre-cooled (0-10 degrees) mixture of methanol and acetone as the extraction solution (methanol: acetone = 1:1 (V / V)), fully shake, so that the algae cells can fully contact with the extraction solution , and then placed in an ice-water bath for 5 minutes in the dark. Nitrogen was used to prevent oxidation during the extraction process. The supernatant was collected by centrifugation, and the precipitate was extracted once again with the extraction solution at a ratio of 5 ml / g. Centrifuge and collect the supernatant. The extract was filtered through a filter membrane with a pore size o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com