Method for preparing poly ethylene glycol-phosphatidyl ethanolamine

A technology of phosphatidylethanolamine and polyethylene glycol, which is applied in the field of biomedical materials, can solve the problems of difficult separation and purification of products, mild reaction conditions, and poor universality, and achieve easy separation and purification of products, low cost, and applicable broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

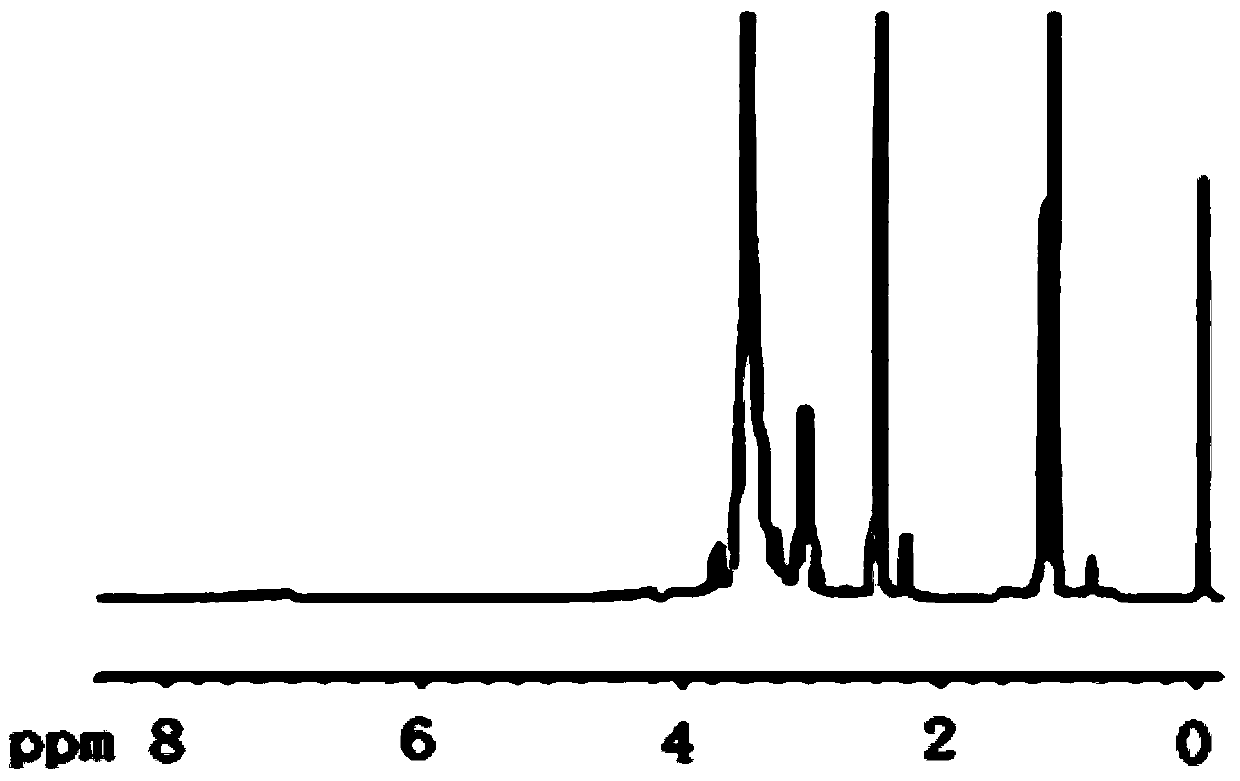

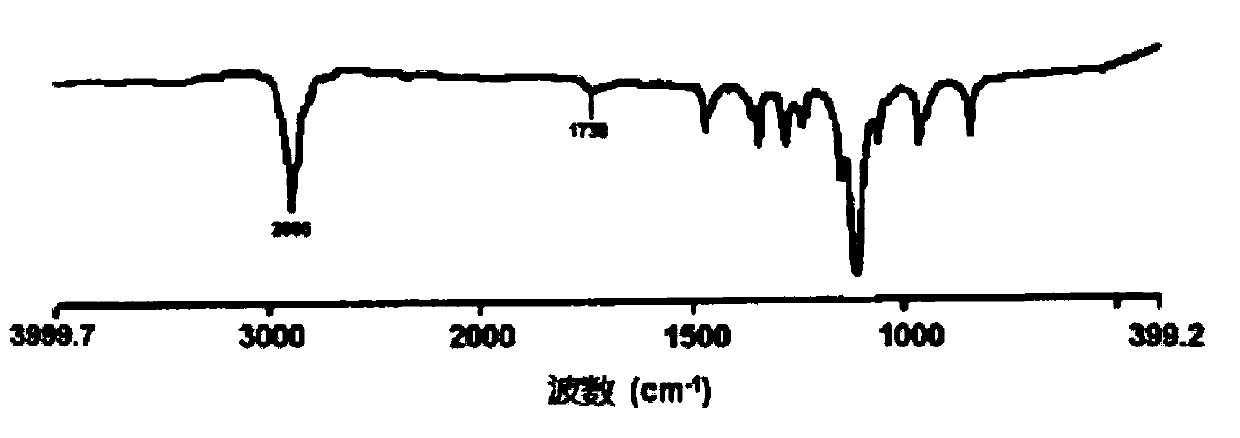

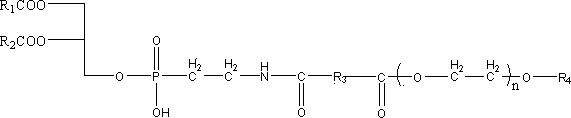

[0025] Example 1: Dissolve 10 grams of monomethyl polyethylene glycol with a molecular weight of 15,000 in 1,000 milliliters of chloroform, and use succinic anhydride (the molar ratio of succinic anhydride to polyethylene glycol terminal hydroxyl group is 10:1) and polyethylene glycol Diol reaction, under the catalysis of EDC·HCl (the molar ratio of EDC·HCl and polyethylene glycol terminal carboxyl group is 2:1), add N-hydroxysuccinimide (N-hydroxysuccinimide and polyethylene glycol The molar ratio of the carboxyl group at the alcohol end is 10:1), then add phosphatidylethanolamine (the molar ratio of polyethylene glycol to phosphatidylethanolamine is 1:1), react at 60°C for 72 hours, and precipitate and purify in ethanol to obtain Polyethylene glycol-phosphatidylethanolamine.

Embodiment 2

[0026] Embodiment 2: 10 grams of monobenzyl polyethylene glycol with a molecular weight of 500 are dissolved in 10 milliliters of dichloromethane, with butenedioic anhydride (the molar ratio of butenedioic anhydride and polyethylene glycol terminal hydroxyl is 1:1 ) react with polyethylene glycol, under the catalysis of DCC (the molar ratio of DCC to polyethylene glycol terminal carboxyl group is 100:1), add N-hydroxysuccinimide (N-hydroxysuccinimide and polyethylene glycol The molar ratio of the carboxyl group at the alcohol end is 2:1), then add phosphatidylethanolamine (the molar ratio of polyethylene glycol to phosphatidylethanolamine is 2:1) and react at 0°C for 48 hours, then recrystallize and purify in methanol, that is Obtain polyethylene glycol-phosphatidylethanolamine.

Embodiment 3

[0027] Embodiment 3: 10 grams of monomethylpolyethylene glycol with a molecular weight of 1500 are dissolved in 100 milliliters of dioxane, and methylbutenedioic anhydride (the mol ratio of butenedioic anhydride to polyethylene glycol terminal hydroxyl is 10:1) react with polyethylene glycol, under the catalysis of EDC (the molar ratio of EDC to polyethylene glycol terminal carboxyl group is 10:1), add N-hydroxysuccinimide (N-hydroxysuccinimide and The molar ratio of polyethylene glycol terminal carboxyl group is 10:1) to activate, then add phosphatidylethanolamine (the molar ratio of polyethylene glycol to phosphatidylethanolamine is 1.2:1) to react at 25°C for 24 hours, crystallize and purify in ethanol , to obtain polyethylene glycol-phosphatidylethanolamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com