A kind of preparation method of wave absorbing composite material as coating or filling layer

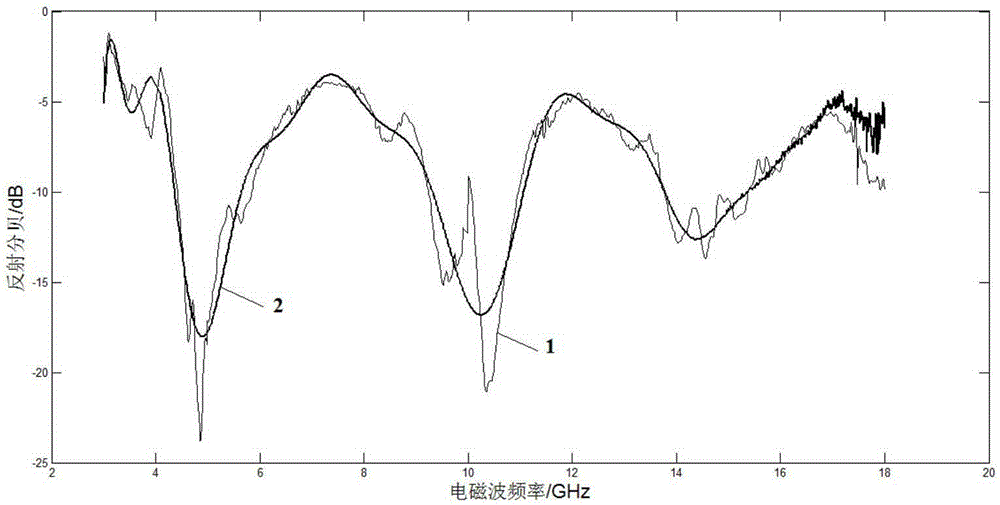

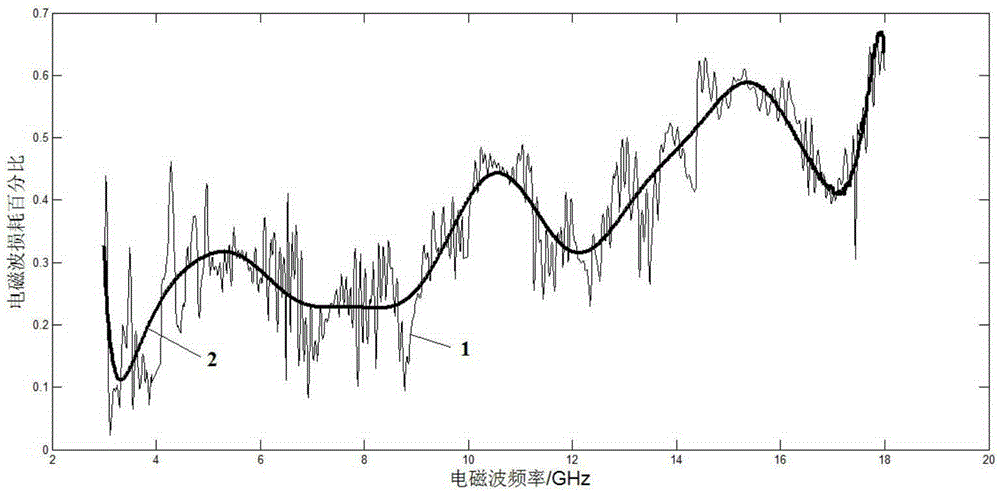

A composite material and filling layer technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of single absorption frequency band, narrow absorption bandwidth, low absorption decibel, etc., and achieve excellent absorption performance and absorption. The effect of widening the bandwidth and increasing the absorbing decibel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] Specific implementation mode 1: This implementation mode is a preparation method of a wave-absorbing composite material as a coating or filling layer, which is completed according to the following steps:

[0032] 1. Preparation of polyethylene glycol 6000 / dispersion solvent mixture: mix polyethylene glycol 6000 with dispersion solvent, and stir for 15min to 30min under the condition of rotating speed of 200r / min~400r / min to obtain polyethylene glycol 6000 / Dispersed solvent mixture;

[0033] The concentration of polyethylene glycol 6000 in the polyethylene glycol 6000 / dispersion solvent mixture described in step 1 is 0.01g / mL~0.1g / mL;

[0034] 2. Preparation of mixed solution A: Add carbon nanotubes, lanthanum oxide powder with a particle size of 20nm to 60nm, metal nickel powder with a particle size of 1 μm to 3 μm, and ytterbium oxide powder with a particle size of 2 μm to 4 μm to polyethylene glycol 6000 / dispersion solvent mixed solution to obtain mixed solution A; ...

specific Embodiment approach 2

[0052] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the dispersion solvent described in step one is absolute ethanol, acetone, 1-methyl-2-pyrrolidone, dimethyl sulfoxide or dimethyl formaldehyde amides. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0053] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the carbon nanotubes described in step 2 are single-walled carbon nanotubes or multi-walled carbon nanotubes. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com