Novel polylactic acid and ionic liquid blending flameresistant material and preparation method thereof

An ionic liquid, flame retardant material technology, applied in the field of flame retardant materials, can solve the problem of high flame retardant additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

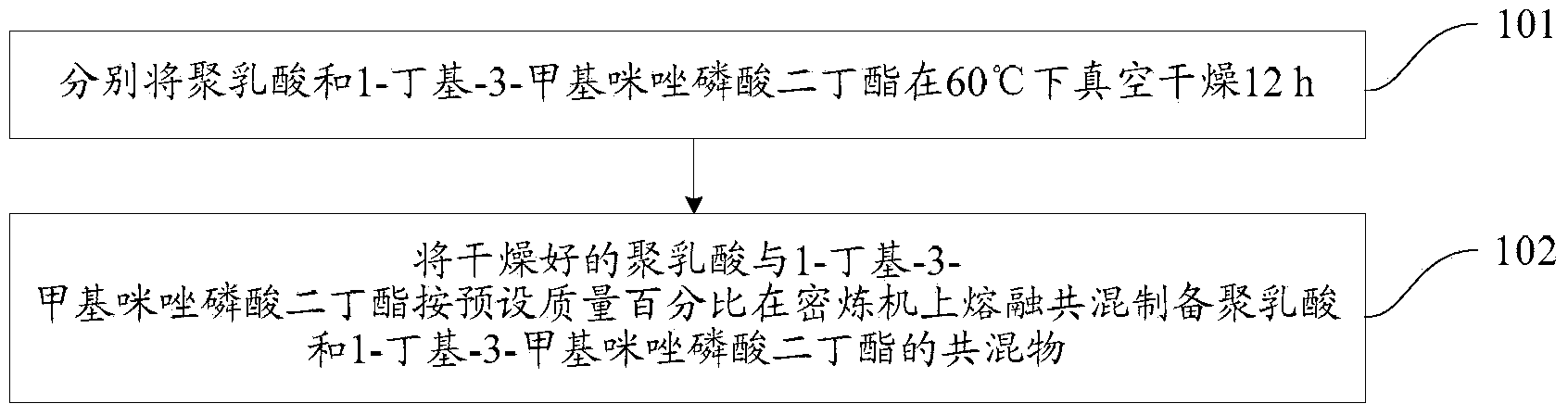

[0025] The invention provides a preparation method of a novel polylactic acid and ionic liquid blended flame retardant material, comprising:

[0026] Step 101, respectively drying polylactic acid and 1-butyl-3-methylimidazolium dibutyl phosphate in vacuum at 60° C. for 12 hours.

[0027] Among them, the purpose of vacuum drying is to remove the moisture adsorbed in the material.

[0028] The invention prepares a novel flame-retardant material through polylactic acid PLA and an ionic liquid (IL), and the ionic liquid is 1-butyl-3-methylimidazolium dibutyl phosphate.

[0029] Step 102, adding the dried polylactic acid and 1-butyl-3-methylimidazolium dibutyl phosphate into the internal mixer according to the preset mass percentage to carry out melt blending, provided by the rotor of the internal mixer The strong shear action makes the 1-butyl-3-methylimidazolium dibutyl phosphate uniformly dispersed in the melt of the polylactic acid to obtain the polylactic acid and the 1-butyl...

Embodiment 1

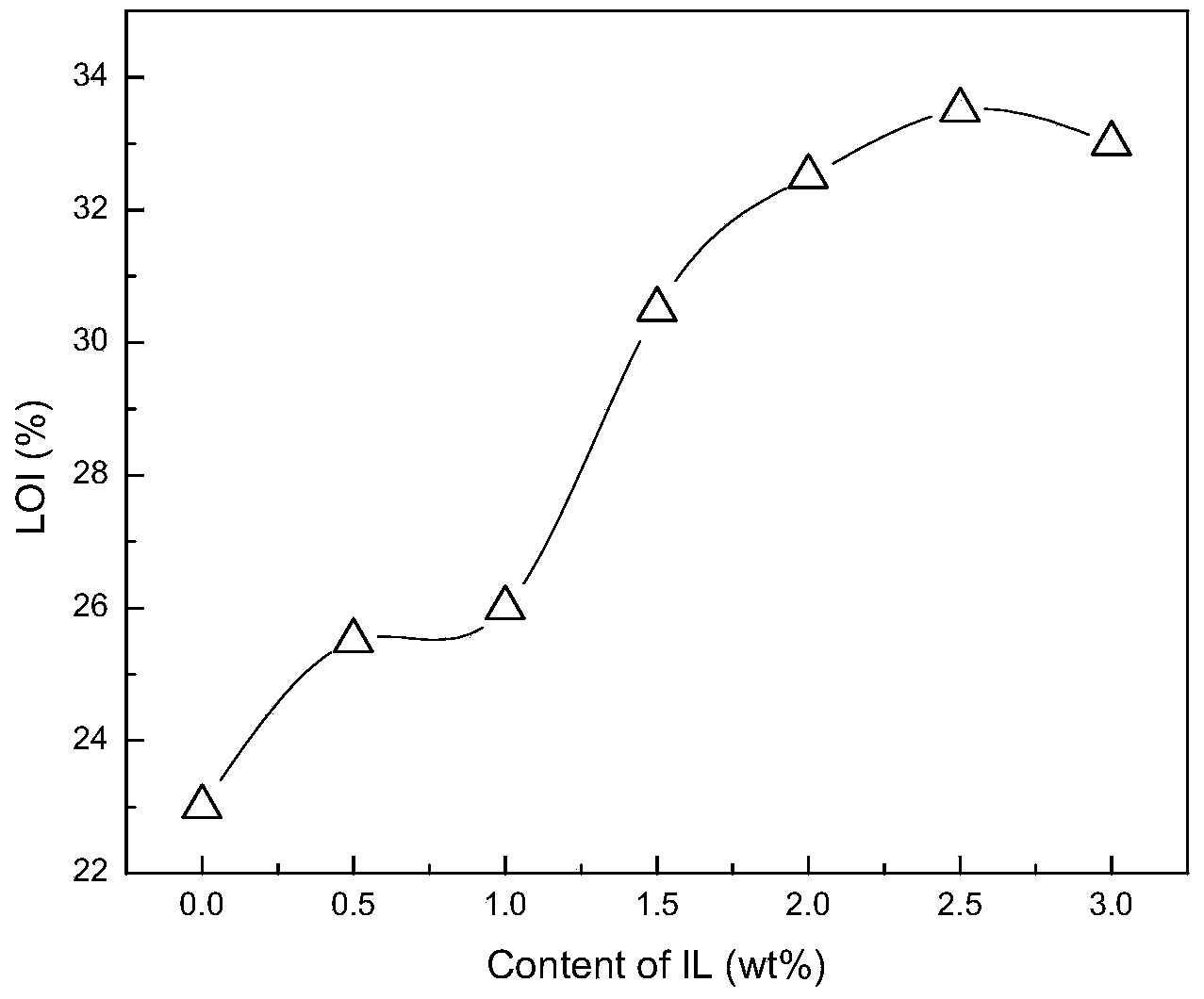

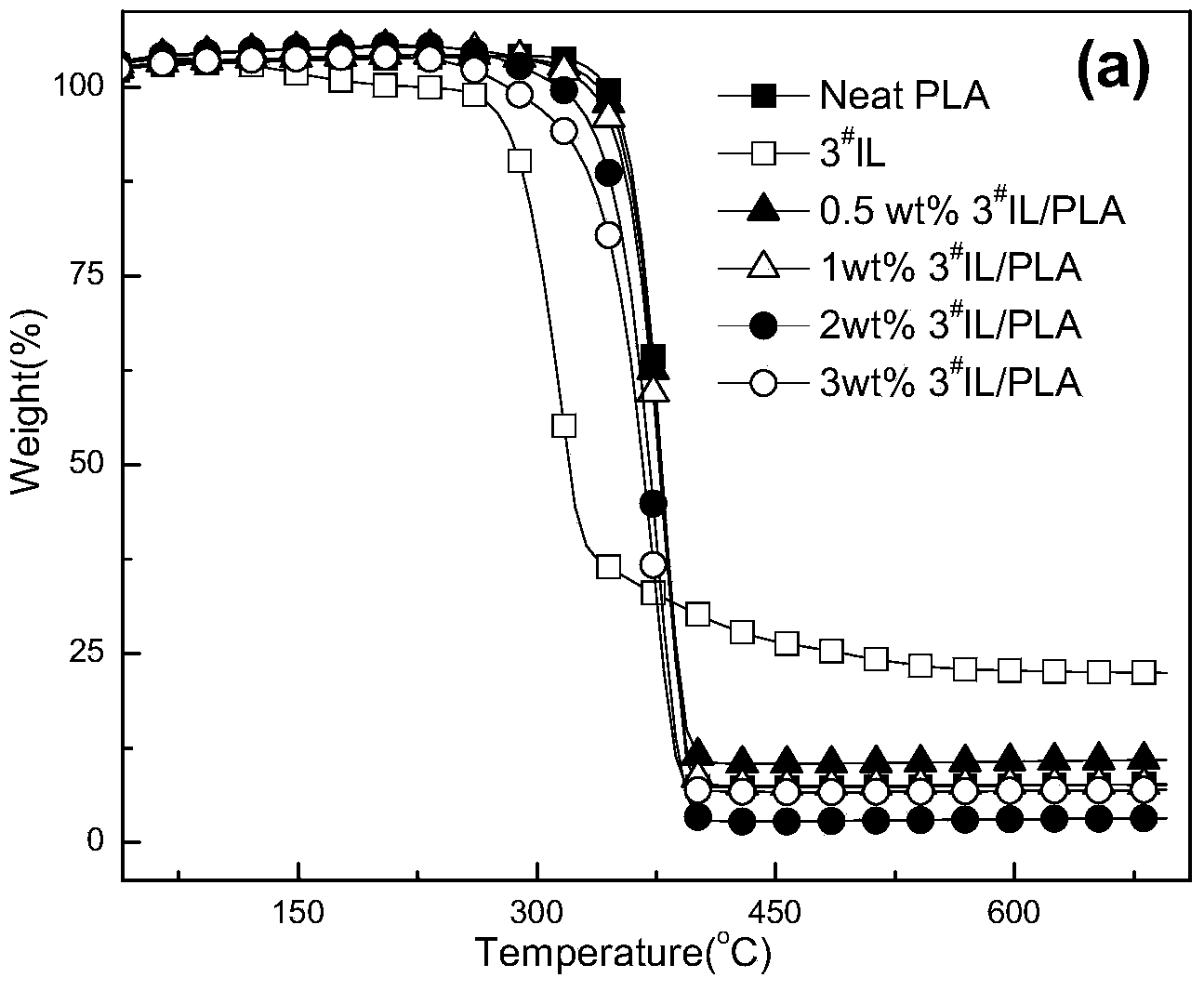

[0039] In the present invention, a small amount of 1-butyl-3-methylimidazolium dibutyl phosphate is blended with PLA to prepare a flame-retardant material, and the present invention is implemented by means of the limiting oxygen index method (LOI), UL-94 method and TGA test below The flame retardant properties of the blends were characterized.

[0040] 1. Experimental part

[0041] Ingredients include:

[0042] Polylactic acid (PLA), 4032D, Nature Works, USA.

[0043] Ionic liquid (IL), 1-butyl-3-methylimidazolium dibutyl phosphate, Shanghai Chengjie Chemical Co., Ltd.

[0044] Instruments and equipment include:

[0045] Internal mixer, XS-60, Shanghai Kechuang Rubber Co., Ltd.

[0046] Oxygen index meter, JF-3, China Jiangning Instrument Analysis Company.

[0047] Horizontal vertical combustion, CZF-3, China Jiangning Instrument Analysis Company.

[0048] Electronic tensile testing machine, XLW, Jinan Languang Electromechanical Technology Co., Ltd.

[0049] Thermogravime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com