A kind of heat-conducting resin composition and preparation method thereof

A technology of thermally conductive resin and composition, which is applied in the field of thermally conductive resin composition and its preparation, which can solve the problems that resin materials cannot provide high enough thermal conductivity or mechanical strength, and achieve the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

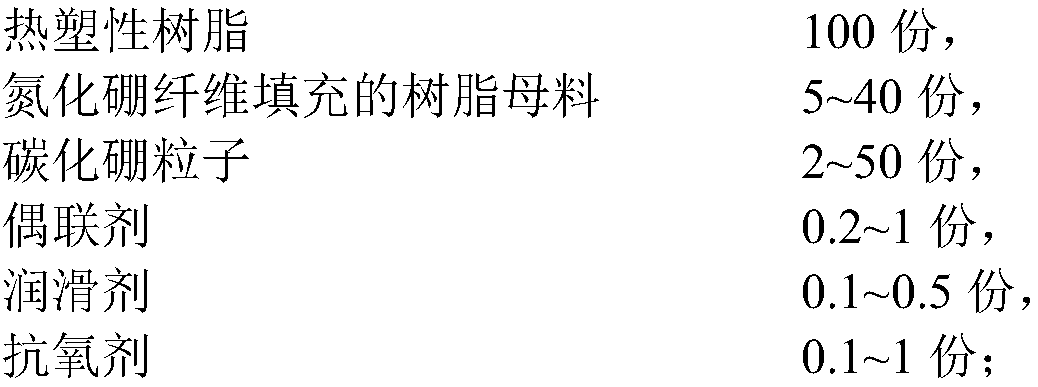

Method used

Image

Examples

Embodiment 1

[0039] After mixing 15 parts by weight of polyamide resin and 25 parts by weight of boron nitride fibers with a diameter of 50 μm in a high-speed mixer for 3 minutes, the polyamide resin matrix filled with boron nitride fibers was prepared by the melt kneading and blending method of screw extrusion. The temperature of the twin-screw extruder from the feed port to the extrusion die is 170°C, 190°C, 210°C, 220°C, 220°C, and the speed of the main engine is 20 Hz.

[0040] 40 parts by weight of the boron nitride fiber-filled resin masterbatch made, with 100 parts by weight of polyamide resin, 2 parts by weight of boron carbide particles with a number average particle diameter of 150 μm, 0.5 parts by weight of tetrakis[β-(3,5- Di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 1 weight part of γ-aminopropyltriethoxysilane, 0.5 weight part of calcium stearate, after mixing in proportion, adopt the molten Kneading and blending method is used to make thermal conductive ...

Embodiment 2

[0043] After mixing 4 parts by weight of polycarbonate resin and 1 part by weight of boron nitride fibers with a diameter of 1 μm in a high-speed mixer for 5 minutes, the boron nitride fiber-filled polycarbonate was prepared by the melt kneading and blending method of screw extrusion. Resin masterbatch, wherein the temperature of the twin-screw extruder from the feed port to the extrusion die is 190°C, 220°C, 230°C, 240°C, 240°C, and the speed of the main engine is 40 Hz.

[0044] 5 parts by weight of the boron nitride fiber-filled resin masterbatch made, with 100 parts by weight of polycarbonate resin, 20 parts by weight of boron carbide particles with a number average particle diameter of 10 μm, 0.8 parts by weight of three (2,4-ditertiary Butylphenyl) phosphite, 0.5 parts by weight of γ-glycidyl etheroxypropyl trimethoxysilane, 0.3 parts by weight of lauric acid diethanolamide, after mixing in proportion, adopt the melt kneading and blending method of screw extrusion to prep...

Embodiment 3

[0048] After mixing 9 parts by weight of polyphenylene sulfide resin and 15 parts by weight of boron nitride fiber with a diameter of 25 μm in a high-speed mixer for 4 minutes, the polyphenylene nitride fiber filled with boron nitride fiber was prepared by the melt kneading and blending method of screw extrusion. Thioether resin masterbatch, wherein the temperature of the twin-screw extruder from the feed port to the extrusion die is 180°C, 200°C, 220°C, 230°C, 230°C, and the speed of the main engine is 30 Hz.

[0049] 24 parts by weight of the boron nitride fiber-filled resin masterbatch made, and 100 parts by weight of polyphenylene sulfide resin, 50 parts by weight of boron carbide particles with a number average particle diameter of 80 μm, 1 part by weight of β-(4-hydroxyl- 3,5-di-tert-butylphenyl) n-octadecyl propionate, 0.2 parts by weight of γ-(methacryloyloxy)propyl trimethoxysilane, 0.3 parts by weight of lauric acid diethanolamide, proportional After mixing, the heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com