Antibacterial powder coating and preparation method thereof

An antibacterial powder and coating technology, applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of large environmental pollution, hidden safety hazards, and poor antibacterial performance, and achieve the effect of widespread promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

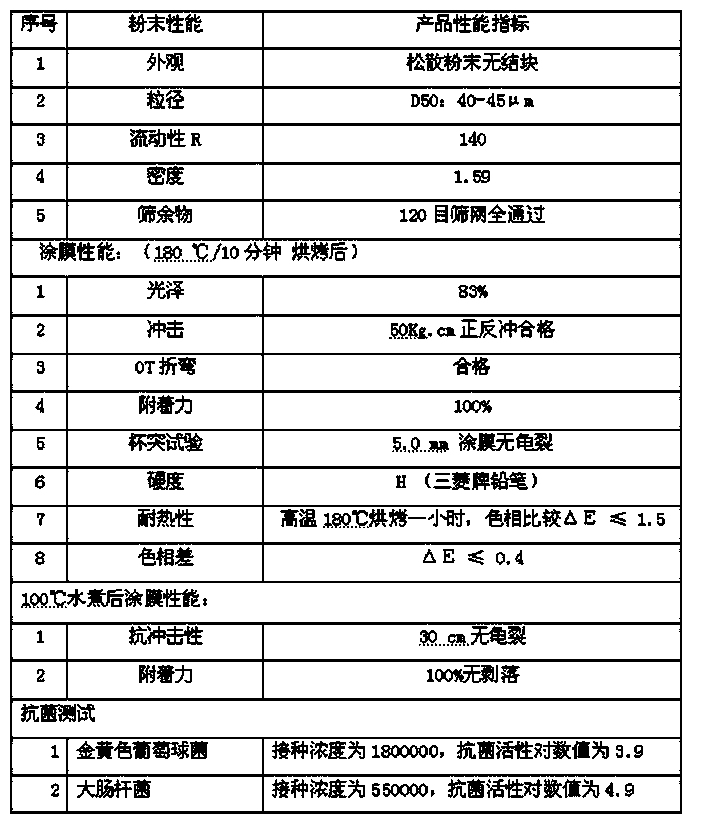

Image

Examples

Embodiment 1

[0050] An antibacterial powder coating containing the following components in parts by mass,

[0051] 23 parts of epoxy resin E-12;

[0052] 35 parts of low acid value polyester resin (50);

[0053] 0.8 part of leveling agent;

[0054] 0.8 part of brightener;

[0055] 22 parts of titanium dioxide;

[0056] 15.77 parts of barium sulfate;

[0057] Inorganic antibacterial agent 0.6 part;

[0058] Antioxidant AT-626 0.6 copies;

[0059] 0.4 part of wax powder;

[0060] Ultramarine 0.6 servings;

[0061] 0.03 part of carbon black;

[0062] Benzoin 0.4 part;

[0063] Wherein: the water content of the barium sulfate is 0.2%;

[0064] The water content of the titanium dioxide is 0.15%;

[0065] The wax powder is PP wax powder.

Embodiment 2

[0067] An antibacterial powder coating containing the following components in parts by mass,

[0068] 25 parts of epoxy resin E-12;

[0069] 38 parts of low acid value polyester resin (50);

[0070] 1 leveling agent;

[0071] 1 part of brightener;

[0072] 22 parts of titanium dioxide;

[0073] 9.96 parts of barium sulfate;

[0074] Inorganic antibacterial agent 0.6 part;

[0075] Antioxidant AT-626 0.6 copies;

[0076] 0.5 part of wax powder;

[0077] Ultramarine 0.8 servings;

[0078] 0.04 part of carbon black;

[0079] Benzoin 0.5 servings.

[0080] Wherein: the water content of the barium sulfate is 0.28%;

[0081] The water content of the titanium dioxide is 0.23%;

[0082] The wax powder is PP wax powder.

Embodiment 3

[0084]An antibacterial powder coating containing the following components in parts by mass,

[0085] 27 parts of epoxy resin E-12;

[0086] 40 parts of low acid value polyester resin (50);

[0087] 0.8 part of leveling agent;

[0088] 0.8 part of brightener;

[0089] 22 parts of titanium dioxide;

[0090] 6.77 parts of barium sulfate;

[0091] Inorganic antibacterial agent 0.6 part;

[0092] Antioxidant AT-626 0.6 copies;

[0093] 0.4 part of wax powder;

[0094] Ultramarine 0.6 servings;

[0095] 0.03 part of carbon black;

[0096] Benzoin 0.4 part;

[0097] Wherein: the water content of the barium sulfate is 0.25%;

[0098] The water content of the titanium dioxide is 0.2%;

[0099] The wax powder is PP wax powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com