Frame sealant composition and display device

A technology of composition and frame sealing glue, which is applied in the direction of adhesive, epoxy resin glue, adhesive type, etc., can solve the problems of non-compliance, increasing the adhesion performance of the sealing glue, insufficient adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

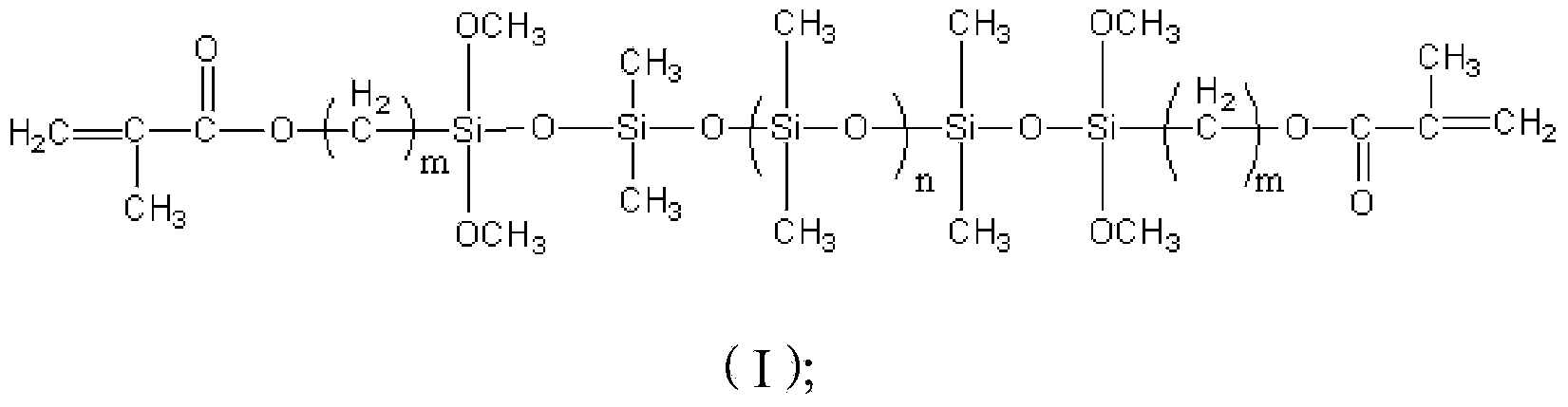

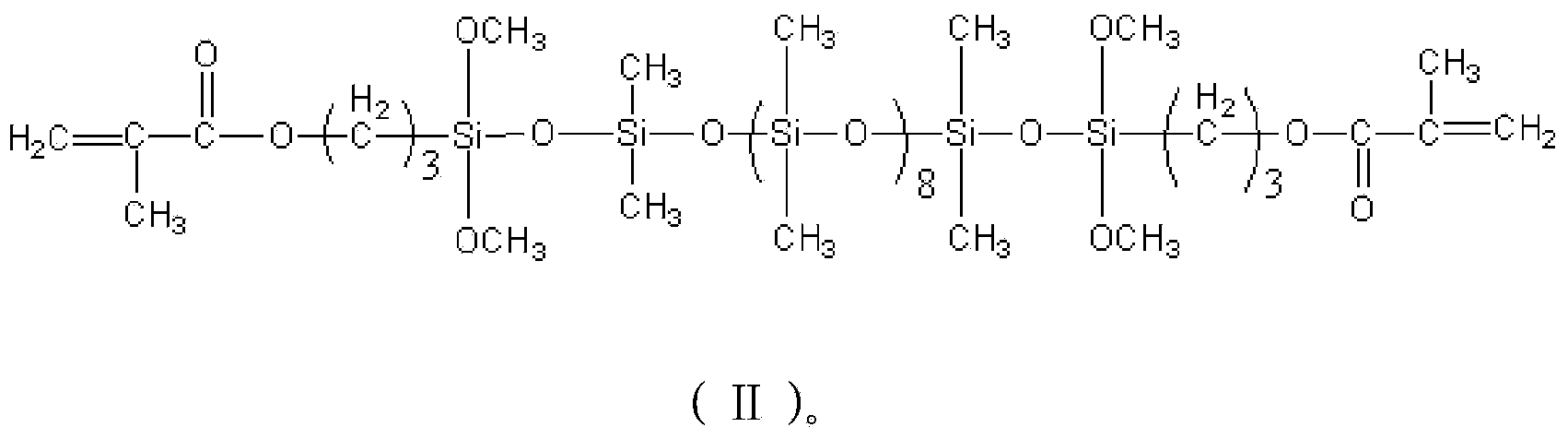

preparation example Construction

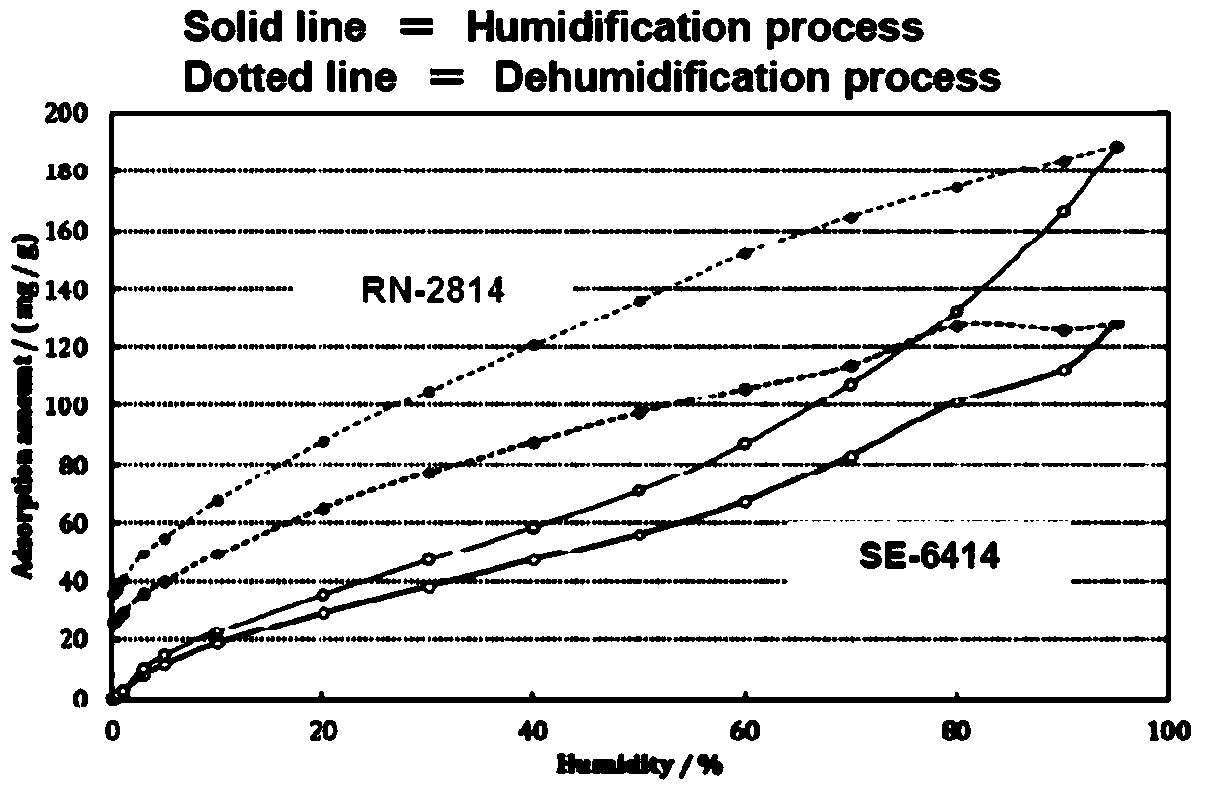

[0042] The preparation method of the above-mentioned dual-curing resin described in the present invention is prior art, such as using hydroxyl-terminated silicone oil (107) (Jinan Hailan Chemical Co., Ltd.) and methacryloxypropyltrimethoxysilane (KH570) ( Sinopharm Group Chemical Reagent Co., Ltd.) as raw materials, prepared by dealcoholization reaction under nitrogen protection, 60°C, dibutyltin dilaurate catalyst (300ppm addition) reaction conditions. In addition, those skilled in the art can also prepare the dual-curing resin through other preparation methods, which is not particularly limited in the present invention.

[0043] Wherein, the secondary sealant composition further includes a photoinitiator. The photoinitiator described in the present invention is obtained by modifying hydrogen-containing silicone oil and 2-hydroxy-2-methyl-1-phenyl-1-propanone.

[0044] The preparation route of above-mentioned photoinitiator is as follows:

[0045]

[0046] Hydrogen-conta...

Embodiment 1

[0074] The preparation of embodiment 1 photoinitiator

[0075] The photoinitiator described in this embodiment is obtained by modifying silicone oil and 2-hydroxy-2-methyl-1-phenyl-1-acetone, and the specific modification method is as follows:

[0076] Using hydrogen-containing silicone oil (PMHS) with a hydrogen content of 0.75mol / g (Shanghai Tuhe Industrial Co., Ltd.), the raw materials of hydrogen-containing silicone oil and 2-hydroxy-2methyl-1-phenyl-1-propanone in tetrahydrofuran solvent Proportion n Si-H :n -OH The ratio is 1:1.1, and the photoinitiator with the following structure is obtained by reacting at 60°C for 10 hours under the catalytic conditions of a basic catalyst:

[0077]

Embodiment 2

[0078] The preparation of embodiment 2 photoinitiators

[0079] Using hydrogen-containing silicone oil (PMHS) with a hydrogen content of 0.8mol / g, the raw material ratio of hydrogen-containing silicone oil and 2-hydroxy-2methyl-1-phenyl-1-propanone in tetrahydrofuran solvent n Si-H :n -OH The ratio is 1:1.15, and the photoinitiator with the following structure is obtained by reacting at 60°C for 9 hours under the catalytic condition of a basic catalyst:

[0080]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com