Preparation method for malformin C

A technology of seed and microbial fermentation, applied in the field of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

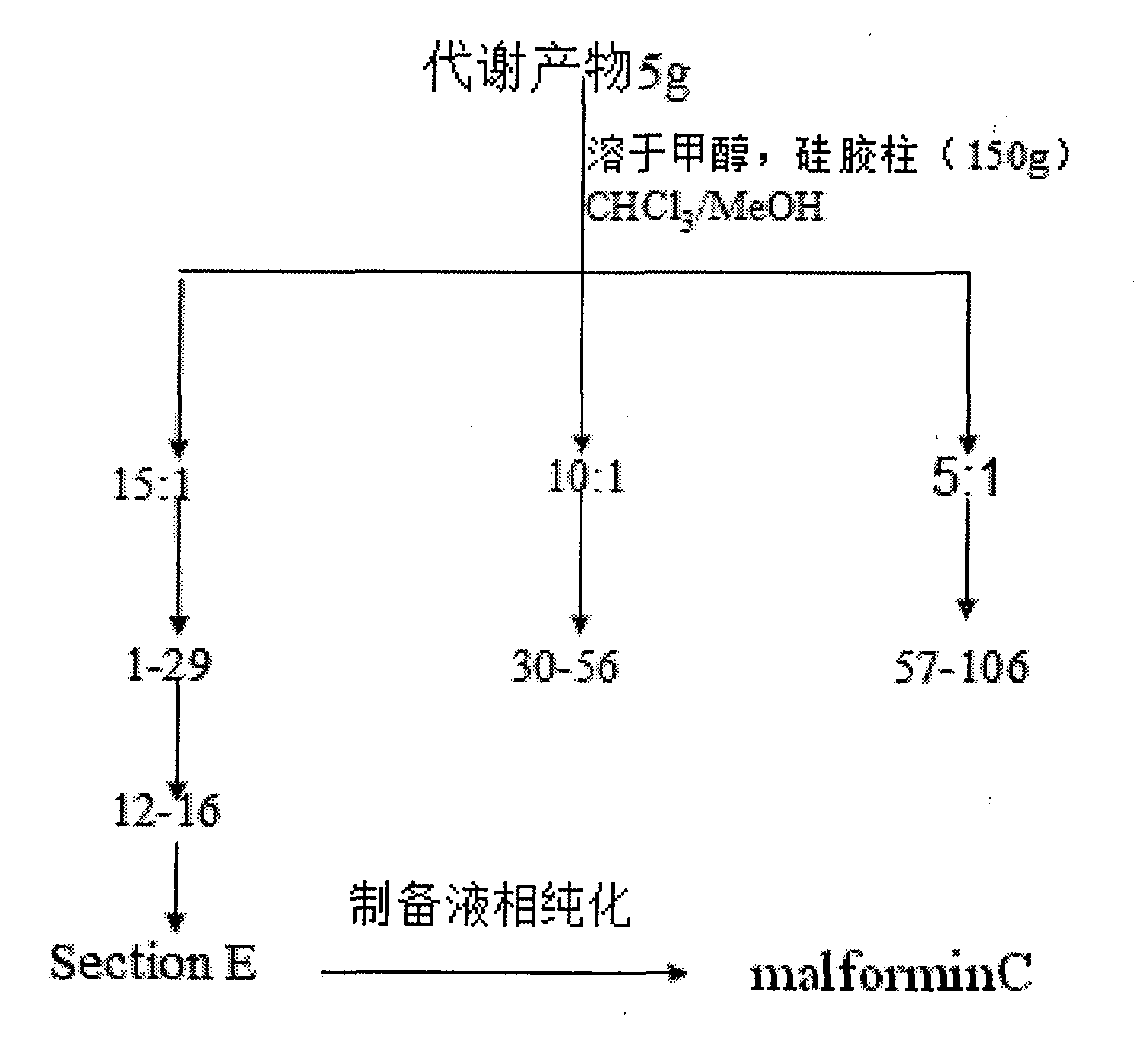

Method used

Image

Examples

Embodiment 1

[0026] Example 1: The characteristics of the fungus SYP2612 of the present invention on different media.

[0027]

[0028] See attached figure 1 : Colony morphology of strain SYP2612.

[0029] Characteristics of strain SYP2612 under light microscope:

[0030] The conidia head is spherical to radial; the conidiophore wall is smooth, the top capsule is spherical, the spore-forming structure is double-layered, and the conidia are spherical, with rough or verrucous projections. See attached figure 2 :Sporangium and spore morphology of strain SYP2612.

[0031] Use molecular biology methods to extract the above-mentioned fungal genomic DNA, using ITS1 and ITS4 (ITS1: 5'-TCC GTC GGT GAA CCT GCG G-3'; ITS4: 5'-TCC TCC GCT TAT TGA TAT GC-3') as The primers were amplified by PCR, sequenced, and the measured sequence was compared with the rRNA homologous sequence in Genbank. 11 strains with higher homology were selected, and Sphingobacterium siyangensis was used as the reference, and the bacte...

Embodiment 2

[0032] Example 2: Method for preparing malformin C by aerobic microbial shake flask fermentation

[0033] 1. Medium

[0034] 1. Slant medium (g / L)

[0035] PDA medium: Potato 200, glucose 10, agar 20, distilled water to prepare pH 7.2-7.4 121 ℃ 30min

[0036] Preparation of potato juice: Take 200g of peeled potatoes, cut into small pieces, boil them in 1000ml of water for one hour, and filter, and make up the filtrate to 1000ml with distilled water.

[0037] 2. Shake flask seed medium (g / L)

[0038]

[0039] 3. Shake flask and fermenter fermentation medium (g / L) Is the medium of shake flask and fermentor the same?

[0040]

[0041] 2. Aerobic microbial fermentation process

[0042] 1. Slope activation of strains: open the freeze-dried tube of strain skimmed milk, pick a small amount of powder and evenly spread it on the above-mentioned sterilized slant, cultivate it at 28℃ for 5-7 days, the lawn grows dense and cloth. Full of sloping surface, no bacteria, store in refrigerator at 4℃.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com