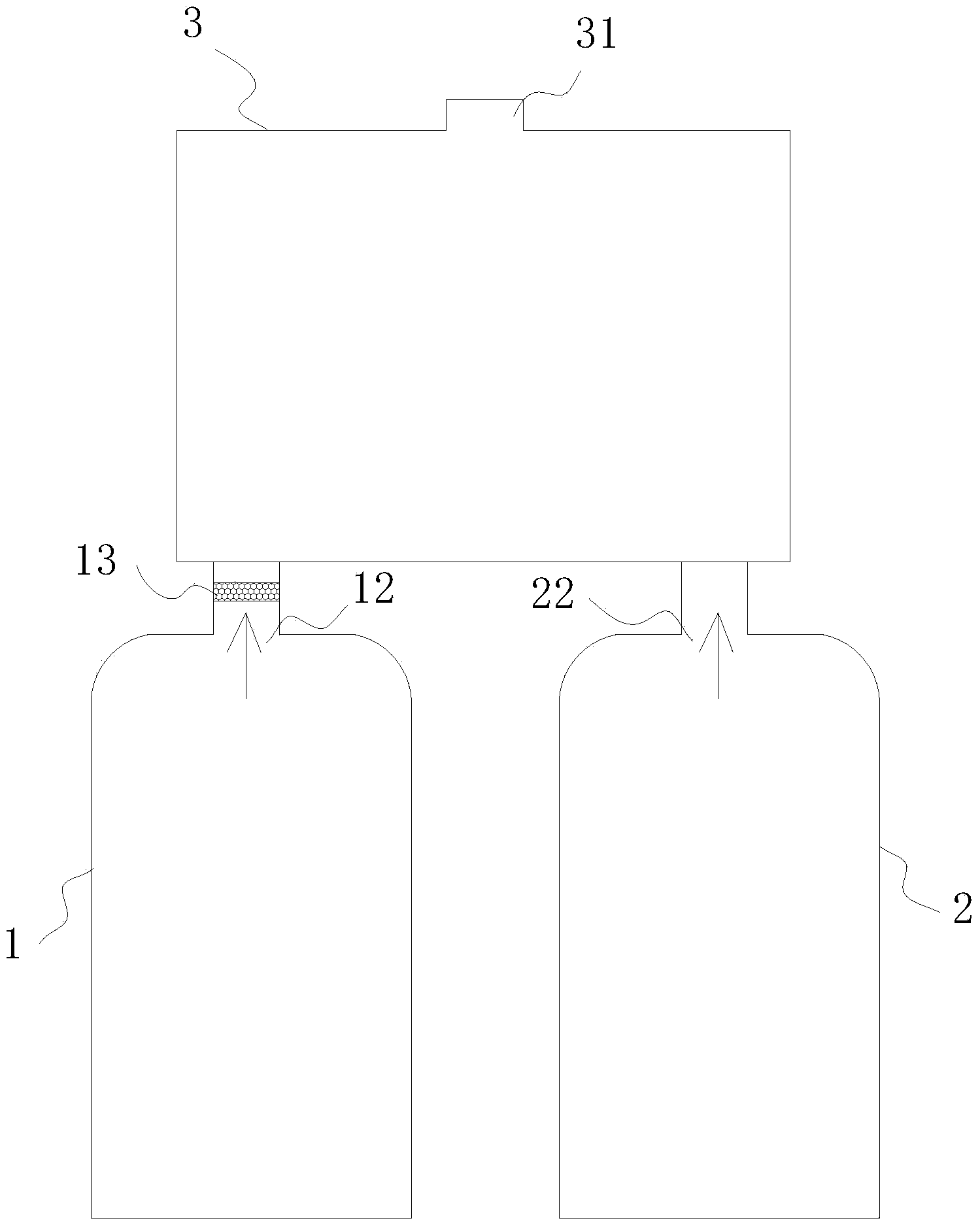

Copper-base alloy hydrogen storage device

A hydrogen storage device and hydrogen storage technology, which are applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, fuel cells, etc. The effect of environmental pollution and broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A copper-based alloy containing the following mass % chemical elements is used to prepare the hydrogen storage bottle of the solid-state hydrogen storage device of the present invention, aluminum 12, beryllium 0.8, boron 0.2, chromium 0.2, titanium 0.08, cerium 0.1 and the balance of copper. The wall thickness of the hydrogen storage bottle is 1 mm.

Embodiment 2

[0032] The operation of Example 1 was repeated, except that the mass % of the chemical elements was modified to 20 aluminum, 0.5 beryllium, 0.4 boron, 0.1 chromium, 0.05 titanium, 0.05 lanthanum and the balance of copper. The wall thickness of the hydrogen storage bottle is 7mm.

Embodiment 3

[0034] The operation of Example 1 was repeated, except that the mass % of certain chemical elements was modified to 10 for aluminum, 1.5 for beryllium, and 0.2 for titanium. The wall thickness of the hydrogen storage bottle is modified to 9mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com