Method for Measuring Micro-Impulse Using Linear Frequency Modulated Multi-beam Laser Heterodyne Second Harmonic Method and Torsion Pendulum Method

A linear frequency modulation and laser heterodyne technology, applied in the optical field, can solve the problems of large occasional errors and low measurement accuracy of small impulses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

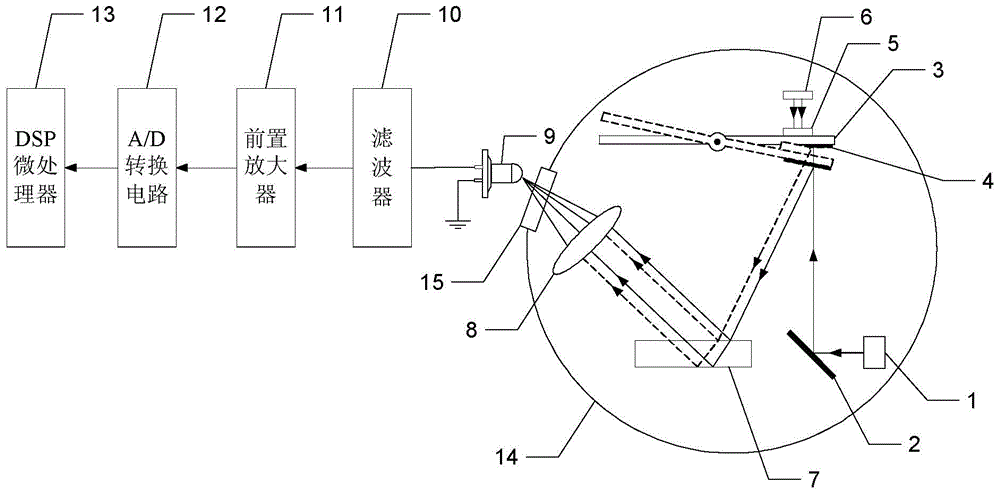

[0034] Specific implementation mode two: the following combination figure 2 Describe this embodiment, this embodiment will further explain the device for measuring the micro-impulse by using the chirp multi-beam laser heterodyne second harmonic method and the torsion method described in the first embodiment. The signal processing system includes a filter 10, a front Amplifier 11, A / D conversion circuit 12 and DSP microprocessor 13;

[0035]The input end of the filter 10 is connected to the electrical signal output end of the photodetector 9; the output end of the filter 10 is connected to the input end of the preamplifier 11; the output end of the preamplifier circuit 11 is connected to the analog signal of the A / D conversion circuit 12 The input end; the digital signal output end of the A / D conversion circuit 12 is connected to the input end of the DSP microprocessor 13 .

specific Embodiment approach 3

[0036] Specific implementation mode three: refer to figure 2 Describe this embodiment in detail, according to the method for measuring the micro-pulse with the device for measuring the micro-pulse by using the chirp multi-beam laser heterodyne second harmonic method and the torsion method described in the second specific embodiment, the method includes the following steps:

[0037] Step 1, turn on chirp laser 1 and pulse laser 6 at the same time;

[0038] Using the pulsed laser 6 to emit pulsed laser light to excite the working medium target 5, so that the working medium target 5 generates plasma spray, and the backspray effect of the plasma spray produced by the working medium target 5 causes the standard beam 3 to rotate;

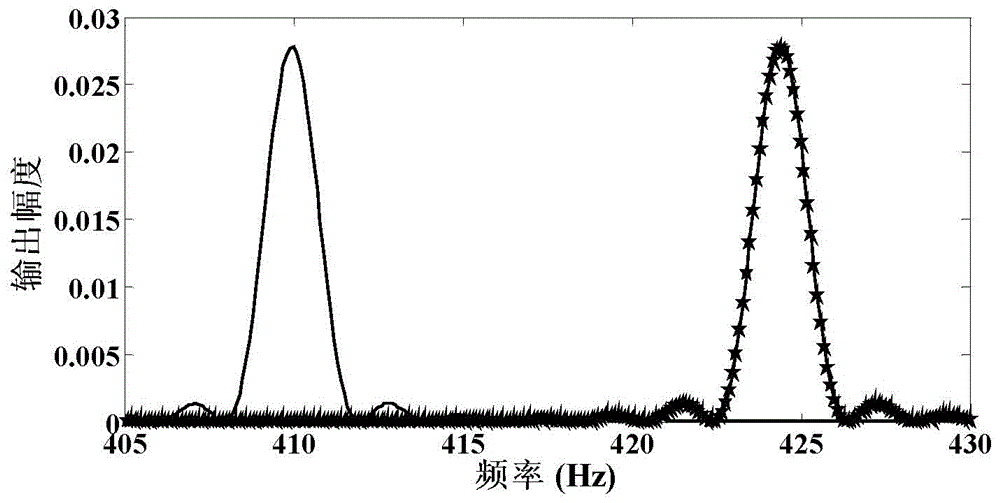

[0039] Step 2: The signal processing system continuously collects the electrical signals sent by the photodetector 9 during the swinging process of the torsion system, and processes the continuously obtained electrical signals, and measures the beam inci...

specific Embodiment approach 4

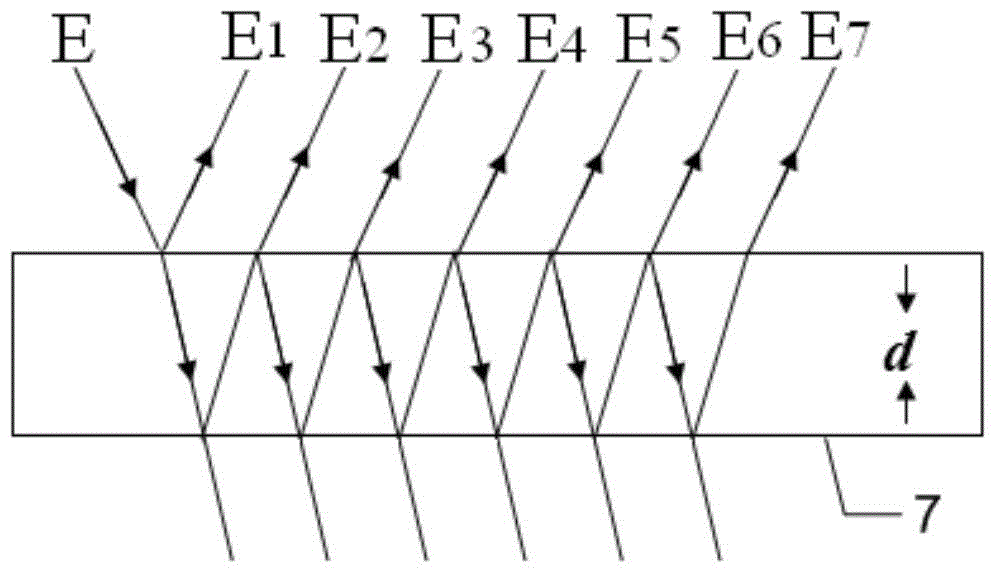

[0045] Embodiment 4: This embodiment is a further description of the method for measuring micro-pulse by using the chirp multi-beam laser heterodyne second harmonic method and the torsion method described in the third embodiment. In step 2, the chirp multi-beam is used The laser heterodyne second harmonic method measures the incident angle θ of the beam incident on the plane standard mirror 7 0 The method of obtaining:

[0046] Step 21, the total light field E of the light beam of photodetector 9 Σ (t):

[0047] E. Σ (t)=E 1 (t)+E 2 (t)+...+E m (t);

[0048] Among them: E 1 (t) is the reflected light field after the light beam is reflected by the front surface of the plane standard mirror 7, and according to the formula

[0049] E 1 ( t ) = α 1 E 0 exp { i [ ω 0 ( t ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com