Capacitive pressure sensor and manufacturing method thereof

A pressure sensor, capacitive technology, used in fluid pressure measurement using capacitance changes, piezoelectric/electrostrictive/magnetostrictive devices, televisions, etc. Large-scale pressure monitoring requirements, difficult process preparation and other problems, to achieve the effect of improving the linear range, high yield, and large linear range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

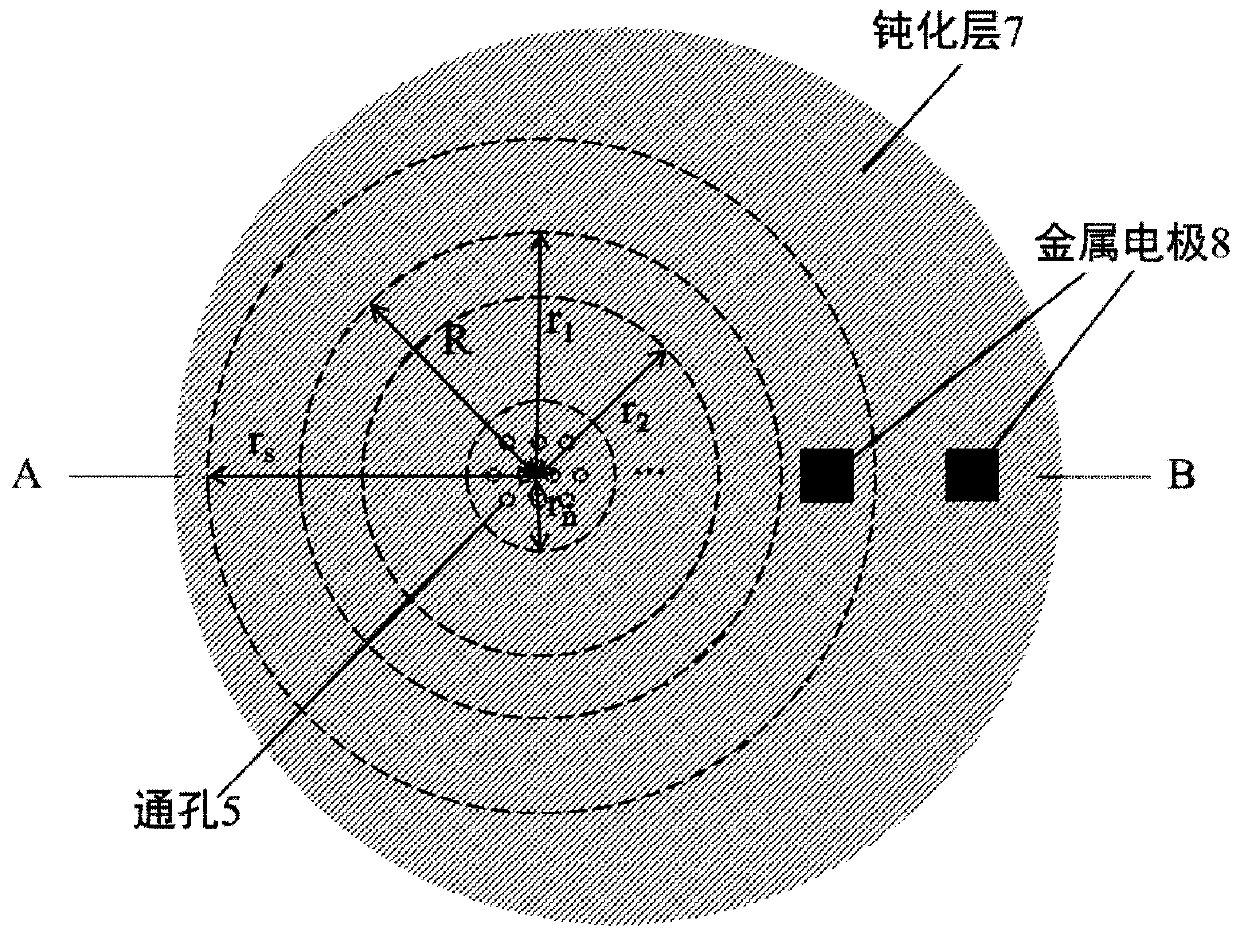

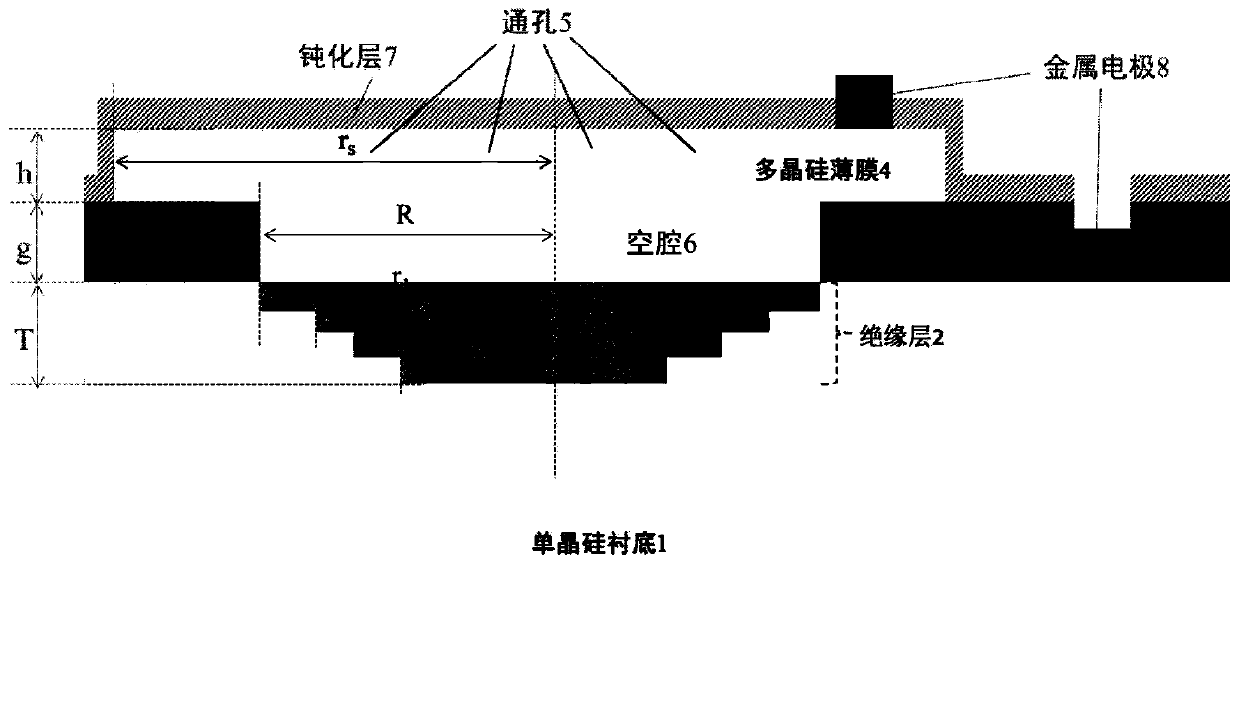

[0050] Example 1: Making the insulating layer as SiO 2 , the isolation layer is SiN, the passivation layer is SiN, and the number of insulating layers is N=2 capacitive pressure sensors.

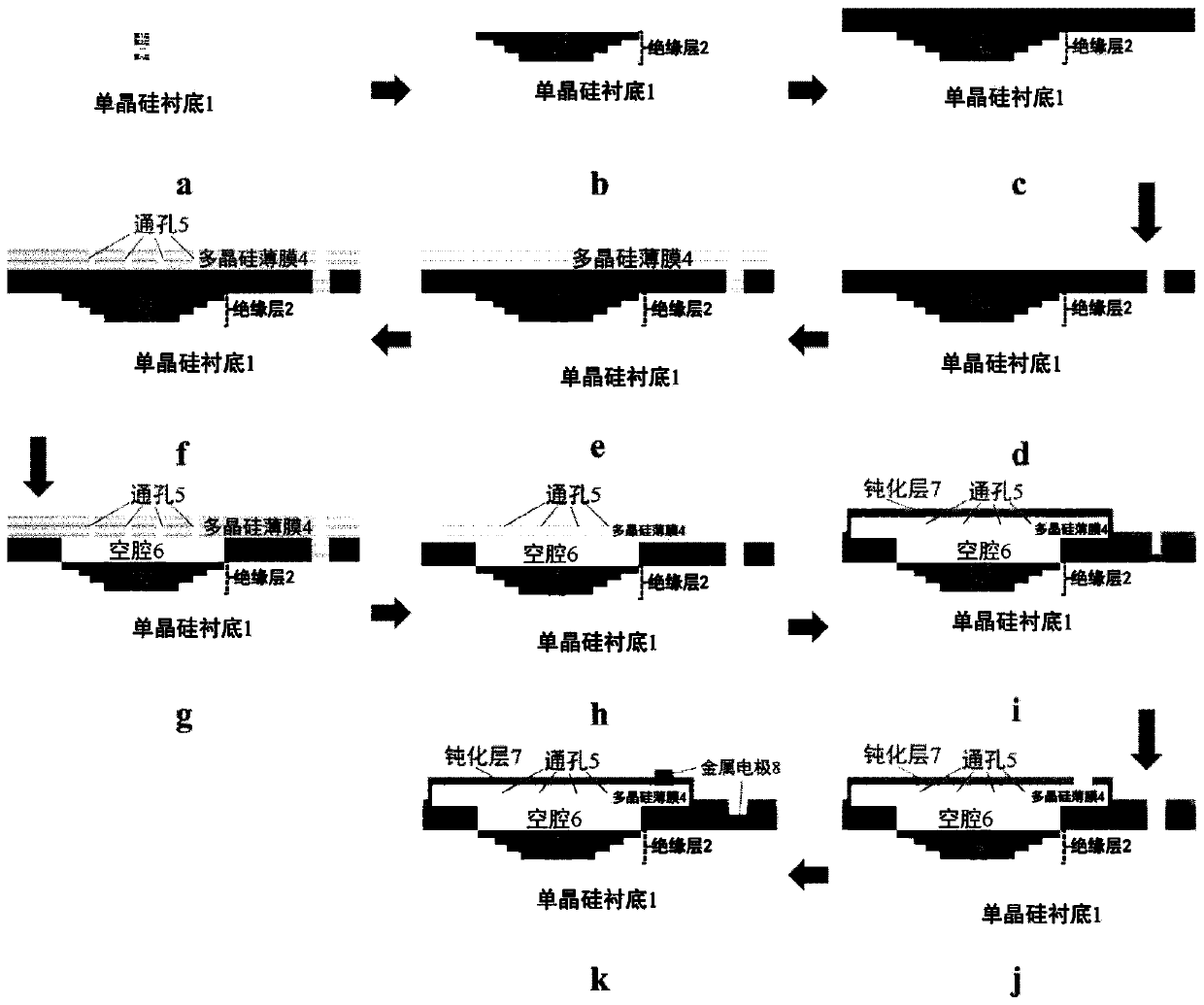

[0051] Step 1, etch the single crystal silicon in the region of the two insulating layers on the single crystal silicon substrate, such as image 3 a.

[0052] 1a) Make a mask on a single crystal silicon substrate, using reactive ion etching technology, that is, on CF 4 Under the process conditions of flow rate of 15sccm, pressure of 10mT and power of 80W, etching thickness t is 125nm, radius r 1 is 100μm of the first layer of insulating layer area;

[0053] 1b) Make a secondary mask on a single crystal silicon substrate, using the same reactive ion etching process conditions as 1a), the etching thickness t is 125nm, the radius r 2 The second insulating layer region is 39 μm.

[0054] Step 2, depositing insulating layer dielectric SiO in the region of the N-layer insulating layer etched...

Embodiment 2

[0074] Example 2: Making the insulating layer as SiO 2 , the isolation layer is SiN, and the passivation layer is Al 2 O 3 , a capacitive pressure sensor with N=4 insulating layers.

[0075] Step 1, etch the single crystal silicon in the area of 4 insulating layers on the single crystal silicon substrate, such as image 3 a.

[0076] 1.1) Make a mask on the single crystal silicon substrate, use reactive ion etching technology to etch the first layer of insulating layer region, the thickness t of the first layer of insulating layer region is 0.1μm, the radius r 1 is 250μm;

[0077] 1.2) Make a secondary mask on the single crystal silicon substrate, use reactive ion etching technology to etch the second insulating layer region, the thickness t of the second insulating layer region is 0.1 μm, and the radius r 2 is 123 μm;

[0078] 1.3) Make three masks on the single crystal silicon substrate, use reactive ion etching technology to etch the third insulating layer region, t...

Embodiment 3

[0102] Example 3: Making the insulating layer as SiO 2 , the isolation layer is SiN, and the passivation layer is HfO 2 , a capacitive pressure sensor with N=5 insulating layers.

[0103] Step A, etching the single crystal silicon in the area of 5 layers of insulating layers on the single crystal silicon substrate, such as image 3 a.

[0104] First, make a mask on the single crystal silicon substrate, and use reactive ion etching technology to etch the first insulating layer region. The thickness t of the first insulating layer region is 0.16μm, and the radius r 1 is 500μm; then a secondary mask is made on the single crystal silicon substrate, using reactive ion etching technology, the etching thickness t is 0.16μm, the radius r 2 The second insulating layer area is 260 μm, and then three masks are made on the single crystal silicon substrate, using reactive ion etching technology, the etching thickness t is 0.16 μm, the radius r 3 It is the third insulating layer area ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com