Two-sided solar cell and manufacturing method thereof

A solar cell, double-sided technology, applied in the field of solar cells, can solve the problems of high resistance and difficult preparation of tunnel junctions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

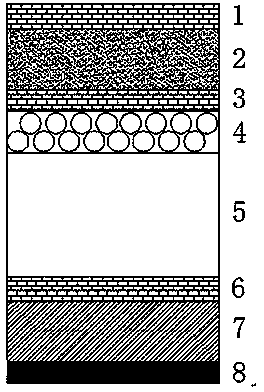

[0034] Preparation of Amorphous Silicon / ZnO Photonic Crystal Reflective Layer / Microcrystalline Silicon Solar Cell

[0035] 1. Clean the ITO glass sheet, deposit PS microspheres on the conductive surface of the glass sheet, and the diameter of the PS microspheres is 300nm.

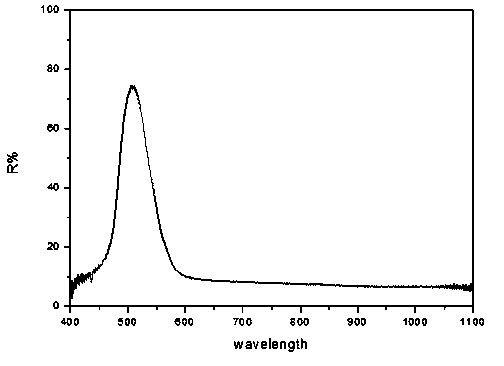

[0036] 2. Using the three-electrode constant potential deposition method, the solution is prepared as follows: configure Zn with zinc nitrate 2+ Concentration 0.02 mol / L, prepared with potassium nitrate (NO 3 ) - The concentration is 0.2mol / L, the pH value is adjusted to be weakly acidic between 5 and 7 with dilute nitric acid, the deposition potential is -0.9V, the deposition temperature is 70°C, and the deposition time is 5000s. After the deposition is completed and dried, it is annealed at 450°C for 2 hours to obtain ZnO with three-dimensional ordered inverse opal structure.

[0037] 3. Deposit a transparent conductive film ITO on ZnO with an inverse opal structure. The transparent conductive film ITO u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com