Microbial fuel cell bonsai and method for in-situ hexavalent chromium-polluted soil remediation

A fuel cell and in-situ remediation technology, applied in biochemical fuel cells, botanical equipment and methods, restoration of contaminated soil, etc., can solve problems such as environmental impact, cumbersome process, and multiple processing, and achieve no management and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

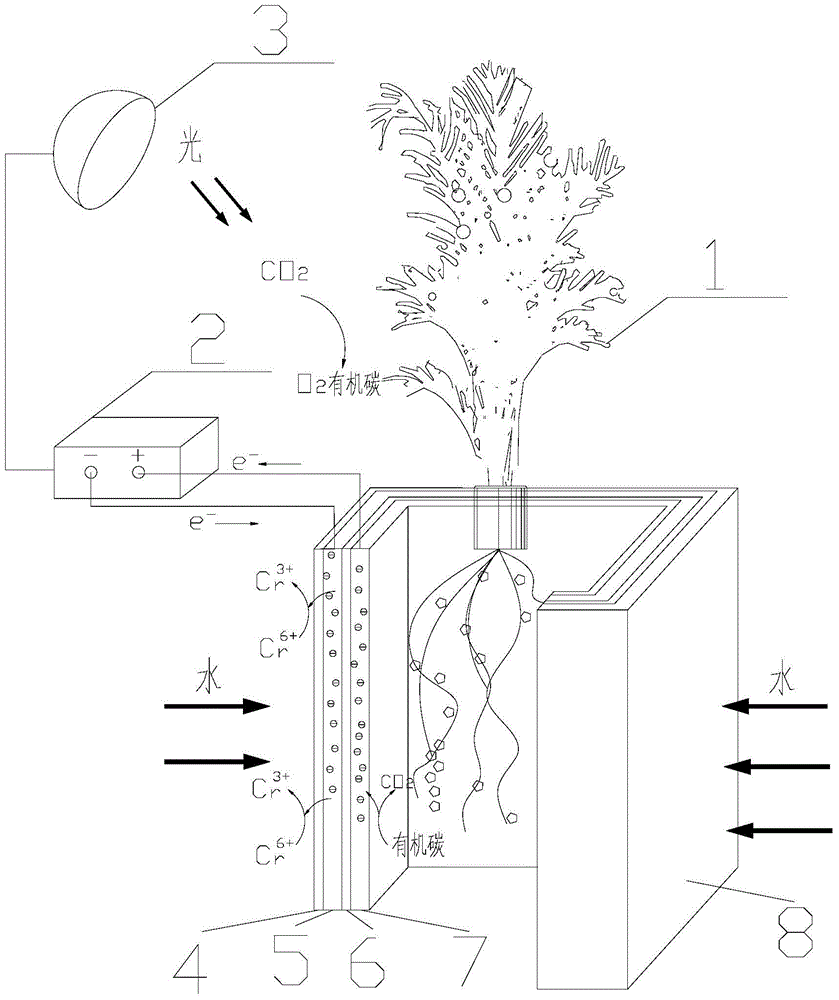

[0041] As shown in Fig. 1, a microbial fuel cell potted plant includes a flowerpot 8, a plant 1, a battery 2, and a light source 3 planted in the flowerpot 8.

[0042] The wall structure of the flowerpot 8 from the outside to the inside is the plastic mesh film layer 4, the graphite cathode layer 5, the glass fiber layer 6 and the graphite anode layer 7; the plastic mesh film layer 4 and the plastic mesh film layer 4 are made of rigid The pore size of the plastic mesh membrane layer is 1-10mm. The graphite cathode layer 5 is detachably connected between the plastic mesh membrane layer 4 and the glass fiber layer 6. The graphite cathode layer can be removed from the plastic mesh membrane The layer 4 and the glass fiber layer 6 are drawn out, and the graphite anode layer 7 is bonded to the glass fiber layer 6.

[0043] The graphite cathode layer 5 and the graphite anode layer 7 are connected to the battery 2 by wires, and the battery 2 is connected to the light source 3, which provid...

Embodiment 2

[0049] The plant selected in this embodiment is sweet potato with a pot diameter of 50 cm and a pot spacing of 50 cm. The anode uses a graphite board with a rough surface, and the cathode uses a graphite board after scratching the surface. Others are the same as in Example 1.

[0050] In this example, the content of hexavalent chromium in the contaminated soil was 800mg / Kg. After 70 days, the hexavalent chromium content dropped to 207mg / kg, and the total chromium dropped to 250mg / kg, reaching the allowable standard of my country's "Soil Environmental Quality Standard" GB15618-1995 After 140 days, the hexavalent chromium content dropped to 45mg / kg, and the total chromium dropped to 50mg / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com