Propanil Wwater dispersible granules

A technology of dispersible granules and dispersants, applied in biocides, biocides, animal repellents, etc., can solve the problems of poor product shape, unreported preparation methods, low suspension rate, etc., and achieve product performance indicators Excellent, safe and pollution-free, resulting in phytotoxicity, avoiding the effect of large amount of emulsifiable solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

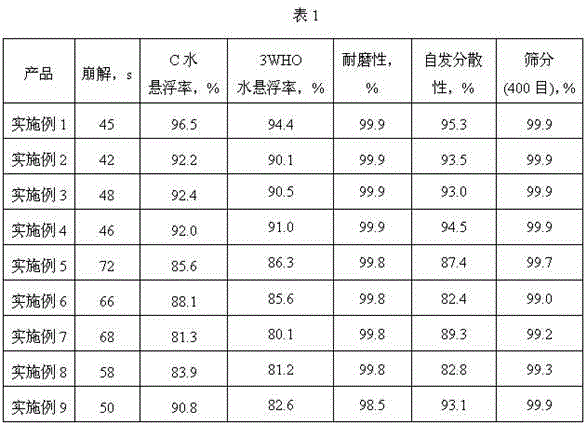

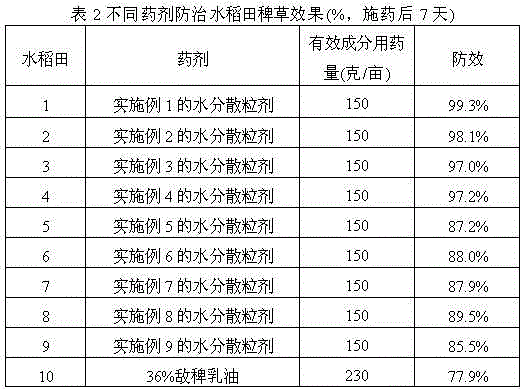

Examples

Embodiment 1

[0028] Embodiment 1 80% propanil water dispersible granules

[0029] Propannil 80%, dispersant polycarboxylate sodium salt 2.5%, maleic acid-acrylic acid copolymer 2.5%, wetting agent dodecylbenzenesulfonate 1.33%, naphthalenesulfonic acid formaldehyde condensate sodium salt 0.67%, Disintegrant ammonium sulfate 5%, binder polyvinylpyrrolidone 1.0%, chelating agent disodium edetate 0.75%, sodium tripolyphosphate 0.75%, cornstarch supplement 100%. After the mixture is fully mixed and uniform, carry out ultrafine airflow pulverization to obtain a 750-mesh fine powder, and then add an appropriate amount of water to the kneader to knead the resulting fine powder, and then granulate it through an extrusion granulator. Dry at ℃ to get 80% propanil water dispersible granules.

Embodiment 2

[0030] Embodiment 2 60% propanil water dispersible granules

[0031] Propaniln 60%, dispersant polycarboxylate sodium salt 2.5%, maleic acid-acrylic acid copolymer 2.5%, wetting agent dodecylbenzenesulfonate 1.33%, naphthalenesulfonic acid formaldehyde condensate sodium salt 0.67%, Disintegrant ammonium sulfate 5%, binder polyvinylpyrrolidone 1.0%, chelating agent disodium edetate 0.75%, sodium tripolyphosphate 0.75%, cornstarch supplement 100%. After the mixture is fully mixed and uniform, carry out ultrafine airflow pulverization to obtain a 700-mesh fine powder, and then knead the obtained fine powder with an appropriate amount of water in a kneader, granulate through an extrusion granulator, and 50 Dry at ℃ to get 60% propanil water dispersible granules.

Embodiment 3

[0032] Embodiment 3 50% propanil water dispersible granules

[0033] Propaniln 50%, dispersant polycarboxylate sodium salt 2.5%, maleic acid-acrylic acid copolymer 2.5%, wetting agent dodecylbenzenesulfonate 1.33%, naphthalenesulfonic acid formaldehyde condensate sodium salt 0.67%, Disintegrant ammonium sulfate 5%, binder polyvinylpyrrolidone 1.0%, chelating agent disodium edetate 0.75%, sodium tripolyphosphate 0.75%, cornstarch supplement 100%. After the mixture is fully mixed and uniform, carry out ultrafine airflow pulverization to obtain a 780-mesh fine powder, and then add an appropriate amount of water to the kneader to knead the resulting fine powder, and then granulate it through an extrusion granulator. Dry at ℃ to get 50% propanil water dispersible granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com