Water dispersible granules containing dicamba salt and atrazine and method for manufacturing water dispersible granules

A technology of dicamba and atrazine, applied in botany equipment and methods, herbicides, algicides, biocides, etc., to achieve the effects of easy popularization and application, good bactericidal effect, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

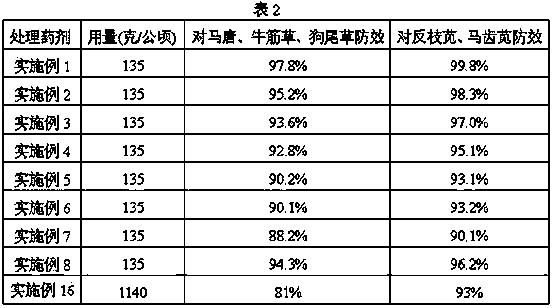

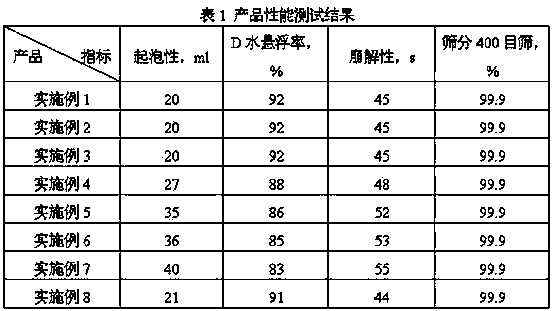

[0032] Example 1 90% dicamba sodium salt · atrazine water dispersible granules

[0033] Wheat straw sodium salt 34%, atrazine 56%, dispersant polycarboxylate sodium salt 1.5%, alkylphenol sulfonate sodium 1%, lignosulfonate calcium 1.5%, wetting agent a-sulfo fatty acid methyl ester 0.1 %, α-olefin sulfonate sodium 1.0%, fatty amide N-methyl taurine sodium salt 0.4%, disintegrant potassium dihydrogen phosphate 1.0%, diammonium hydrogen phosphate 0.32%, potassium chloride 0.18%, kaolin supplement 100%, after the mixture is fully mixed evenly, carry out ultra-fine airflow pulverization to obtain 700 mesh fine powder, then knead the obtained fine powder with an appropriate amount of water in a kneader, granulate through an extrusion granulator, and fluidize in boiling Dry in bed at 65°C to obtain 90% dicamba salt · atrazine water dispersible granules.

Embodiment 2

[0034] Example 2 70.49% dicamba sodium salt · atrazine water dispersible granules

[0035] Dicamba sodium salt 26.6%, atrazine 43.89%, dispersant polycarboxylate sodium salt 1.5%, alkylphenol sulfonate sodium 1%, lignosulfonate calcium 1.5%, wetting agent a-sulfo fatty acid methyl ester 0.1%, sodium a-olefin sulfonate 1.0%, fatty amide N-methyl taurine sodium salt 0.4%, disintegrant potassium dihydrogen phosphate 1.0%, diammonium hydrogen phosphate 0.32%, potassium chloride 0.18%, kaolin Make up 100%, after the mixture is fully mixed evenly, carry out ultra-fine airflow pulverization to obtain 700 mesh fine powder, then knead the obtained fine powder with an appropriate amount of water in a kneader, granulate through an extrusion granulator, and grind in a boiling flow Dry at 65°C in a chemical bed to obtain 70.49% dicamba salt · atrazine water dispersible granules.

Embodiment 3

[0036] Example 3 10.6% dicamba sodium salt · atrazine water dispersible granules

[0037] Dicamba sodium salt 4%, atrazine 6.6%, dispersant polycarboxylate sodium salt 1.5%, alkylphenol sulfonate sodium 1%, calcium lignosulfonate 1.5%, wetting agent a-sulfo fatty acid methyl ester 0.1%, sodium a-olefin sulfonate 1.0%, fatty amide N-methyl taurine sodium salt 0.4%, disintegrant potassium dihydrogen phosphate 1.0%, diammonium hydrogen phosphate 0.32%, potassium chloride 0.18%, kaolin Make up 100%, after the mixture is fully mixed evenly, carry out ultra-fine airflow pulverization to obtain 700 mesh fine powder, then knead the obtained fine powder with an appropriate amount of water in a kneader, granulate through an extrusion granulator, and grind in a boiling flow Dry at 65°C in a chemical bed to obtain 10.6% dicamba salt · atrazine water dispersible granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com