A kind of terbutin water dispersible granule and preparation method thereof

A technology of terbutin and dispersible granules, applied in the field of pesticides, can solve problems such as no reports of high-content terbutin water dispersible granules preparations, etc., and achieve the effects of good control effect, convenient use and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

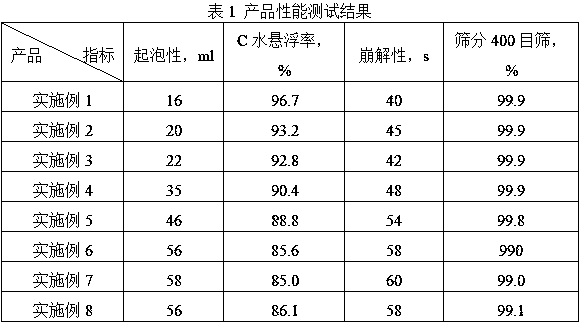

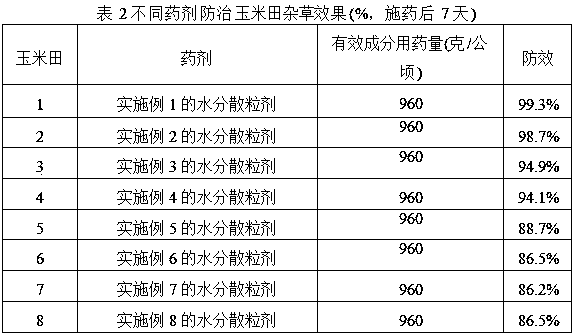

Examples

Embodiment 190

[0022] Embodiment 1 90% terbuthine water-dispersible granules

[0023] Terbutylazine 90%, dispersant sodium polycarboxylate 1.33%, alkylphenol sulfonate sodium 1.33%, calcium lignosulfonate 1.33%, wetting agent a-sulfo fatty acid methyl ester 0.83%, a-olefin sulfonic acid Sodium 0.83% and fatty amide N-methyl taurine sodium salt 0.83%, disintegrant ammonium sulfate 0.5%, diammonium hydrogen phosphate 0.5%, light calcium carbonate make up 100%.

[0024] After the above-mentioned ingredients are fully mixed, carry out ultra-fine airflow pulverization to obtain a 750-mesh fine powder, and then knead the obtained fine powder with an appropriate amount of water (1-5% of the fine powder mass, the same below) in a kneader, It is granulated by an extrusion granulator, and dried in a fluidized fluidized bed at 60°C to obtain 90% terbutyzine water-dispersible granules.

Embodiment 260

[0025] Embodiment 2 60% terbuthine water dispersible granules

[0026] 60% terbutyzine, 1.33% sodium polycarboxylate dispersant, 1.33% sodium alkylphenol sulfonate, 1.33% calcium lignosulfonate, 0.83% wetting agent a-sulfo fatty acid methyl ester, a-olefin sulfonic acid Sodium 0.83% and fatty amide N-methyl taurine sodium salt 0.83%, disintegrant ammonium sulfate 0.5%, diammonium hydrogen phosphate 0.5%, light calcium carbonate make up 100%.

[0027] After the above-mentioned ingredients are fully mixed, carry out ultra-fine jet crushing to obtain 750-mesh fine powder, and then knead the obtained fine powder with an appropriate amount of water in a kneader, granulate through an extrusion granulator, and fluidize in boiling Dry in bed at 60°C to get 60% terbuthine water dispersible granules.

Embodiment 380

[0028] Embodiment 3 80% terbuthine water dispersible granules

[0029] Terbutylazine 80%, dispersant sodium polycarboxylate 1.33%, sodium alkylphenol sulfonate 1.33%, calcium lignosulfonate 1.33%, wetting agent a-sulfo fatty acid methyl ester 0.83%, a-olefin sulfonic acid Sodium 0.83% and fatty amide N-methyl taurine sodium salt 0.83%, disintegrant ammonium sulfate 0.5%, diammonium hydrogen phosphate 0.5%, light calcium carbonate make up 100%.

[0030] After the above-mentioned ingredients are fully mixed, carry out ultra-fine jet crushing to obtain 750-mesh fine powder, and then knead the obtained fine powder with an appropriate amount of water in a kneader, granulate through an extrusion granulator, and fluidize in boiling Dry at 60°C in the bed to obtain 80% terbuthyrine water-dispersible granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com