Finger joint finger tenon comb machine

A mortise-and-comb machine and comb-tooth technology, which is applied in the field of finger-jointed lumber production equipment, can solve the problems of low tenon-tooth processing accuracy, large planing volume, and waste of wood resources, so as to facilitate processing accuracy and improve work efficiency. Efficiency, the effect of ensuring the quality of sawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

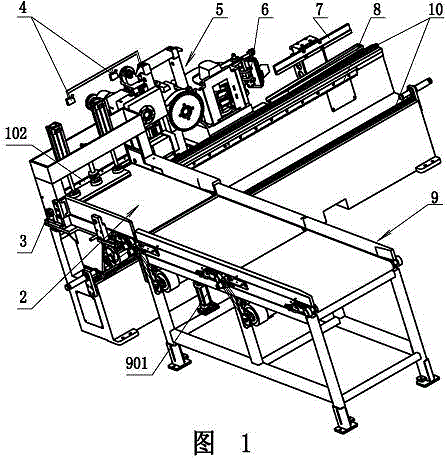

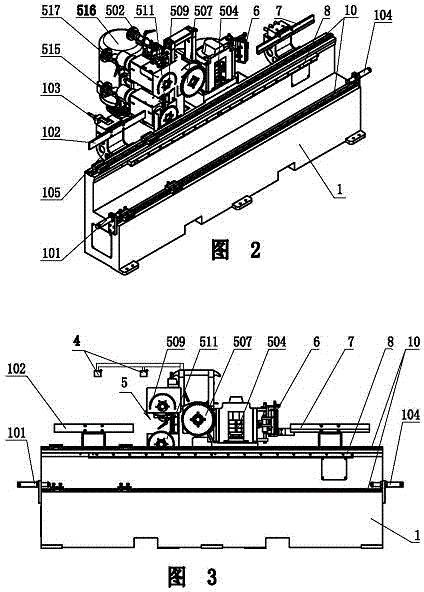

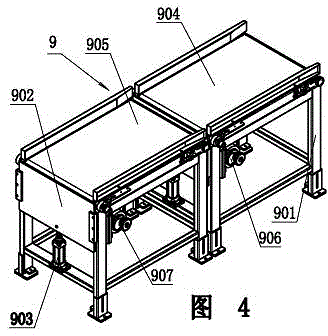

[0035] Such as figure 1 The shown finger joint machine refers to a tenon and tenon comb machine, which includes a comb machine body 1, a tenon and tenon comb milling device 5 fixedly connected to the back side of the comb machine body 1, and five pairs of tenon and tenon comb milling devices The wooden strips are trimmed at the ends and the ends are comb-milled. On the comb machine body 1, a mobile clamping workbench 2 that can slide back and forth along the length direction of the bed is supported by a sliding rail 10. The feeding movement of sawing the end of the bar and combing the tenon. The outer end of the movable clamping workbench 2 is also provided with a fixed fixed feed table 9 , which corresponds to the position of the movable clamping workbench 2 at the left end of the comb machine body 1 . When working, first place the wooden strips on the fixed feeding table 9, and then send the wooden strips on the fixed feeding table 9 to the mobile clamping workbench 2 in b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com