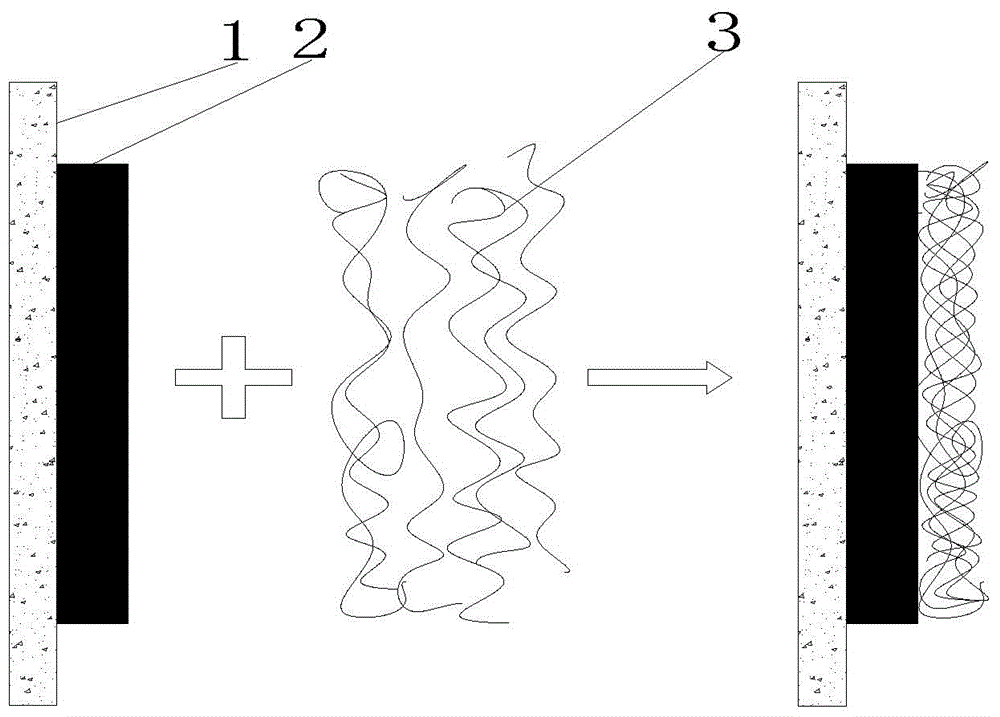

Method for preparing electro-adsorption component by virtue of self-assembly technology

A self-assembly technology and adsorption material technology, applied in the field of preparing electro-adsorption components by self-assembly technology, can solve problems such as unfavorable electric double layer, influence of desalination rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

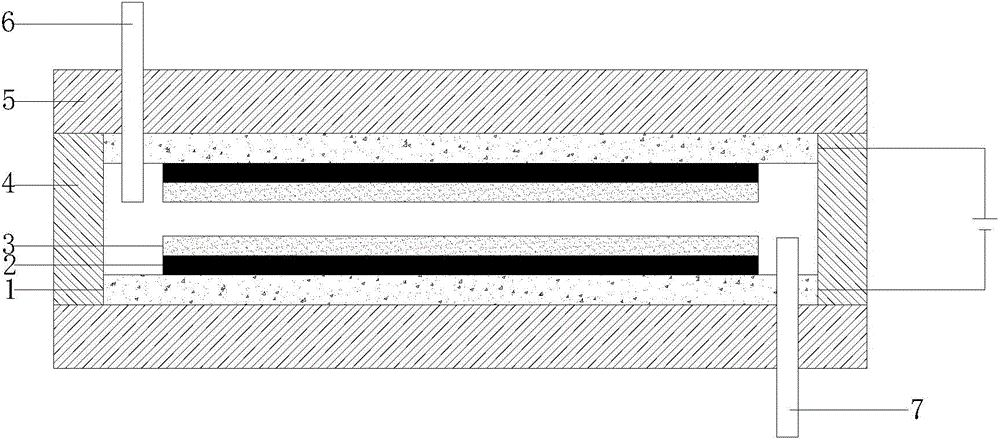

Method used

Image

Examples

example 1

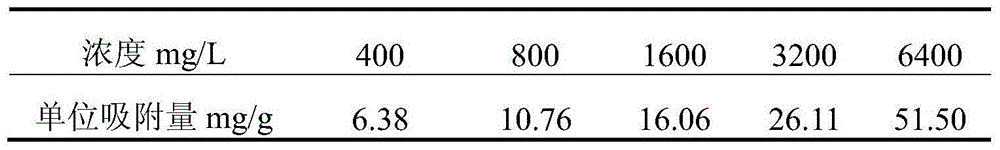

[0031] The technology of the present invention is used to assemble a new type of adsorption component and connect a power supply. The positive electrode of the power supply is connected to the side electrode assembled with the polycation layer, and the negative electrode of the power supply is connected to the side electrode assembled with the polyanion layer. First, use a large amount of deionized water to clean the entire component system to ensure the accuracy of the adsorption results. In the experiment, the electrosorption voltage was controlled at 1.2v, the adsorption temperature was controlled at 25°C, and the electrosorption desalination performance test was carried out. Sodium chloride solutions of different concentrations were selected, and the concentration gradient was set to 400, 800, 1600, 3200, 6400mg / L as the solution to be treated. The adsorption process was set to circulatory system adsorption. The results of electrosorption are shown in the following table: ...

example 2

[0034]The technology of the present invention is used to assemble a new type of adsorption component and connect a power supply. The positive electrode of the power supply is connected to the side electrode assembled with the polycation layer, and the negative electrode of the power supply is connected to the side electrode assembled with the polyanion layer. First, use a large amount of deionized water to clean the entire component system to ensure the accuracy of the adsorption results. In the experiment, the electrosorption voltage was controlled to increase to 1.6v, and the adsorption temperature was controlled to remain unchanged at 25°C, and the electrosorption desalination performance test was carried out. Sodium chloride solutions of different concentrations were selected, and the concentration gradient was set to 400, 800, 1600, 3200, 6400mg / L as the solution to be treated. The adsorption process was set to circulatory system adsorption. The results of electrosorption ...

example 3

[0037] The technology of the present invention is used to assemble a new type of adsorption component and connect a power supply. The positive electrode of the power supply is connected to the side electrode assembled with the polycation layer, and the negative electrode of the power supply is connected to the side electrode assembled with the polyanion layer. First, use a large amount of deionized water to clean the entire component system to ensure the accuracy of the adsorption results. In the experiment, the electrosorption voltage was controlled to be 1.2v, and the adsorption temperature was controlled to be 35°C, and the electrosorption desalination performance test was carried out. Sodium chloride solutions of different concentrations were selected, and the concentration gradient was set to 400, 800, 1600, 3200, 6400mg / L as the solution to be treated. The adsorption process was set to circulatory system adsorption. The results of electrosorption are shown in the followin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com