A kind of low-smoke flame-retardant polyvinyl chloride cable material and preparation method thereof

A polyvinyl chloride cable, low-smoke flame-retardant technology, which is applied to insulated cables, cables, circuits and other directions, can solve the problems of large combustion smoke production, poor flame retardant performance, and high production costs, and achieves simple production process and production process. Easy operation and low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Add 100g polyvinyl chloride and BiFeO 3 20g was dried in a blast oven at 100°C for 1 hour;

[0027] (2) The polyvinyl chloride and BiFeO obtained in step (1) 3 Put 40gDOP, 1gNDZ-311, 5g dibutyltin dilaurate, 0.5g stearic acid, 0.5g calcium stearate into a high-speed mixer, mechanically stir and mix evenly;

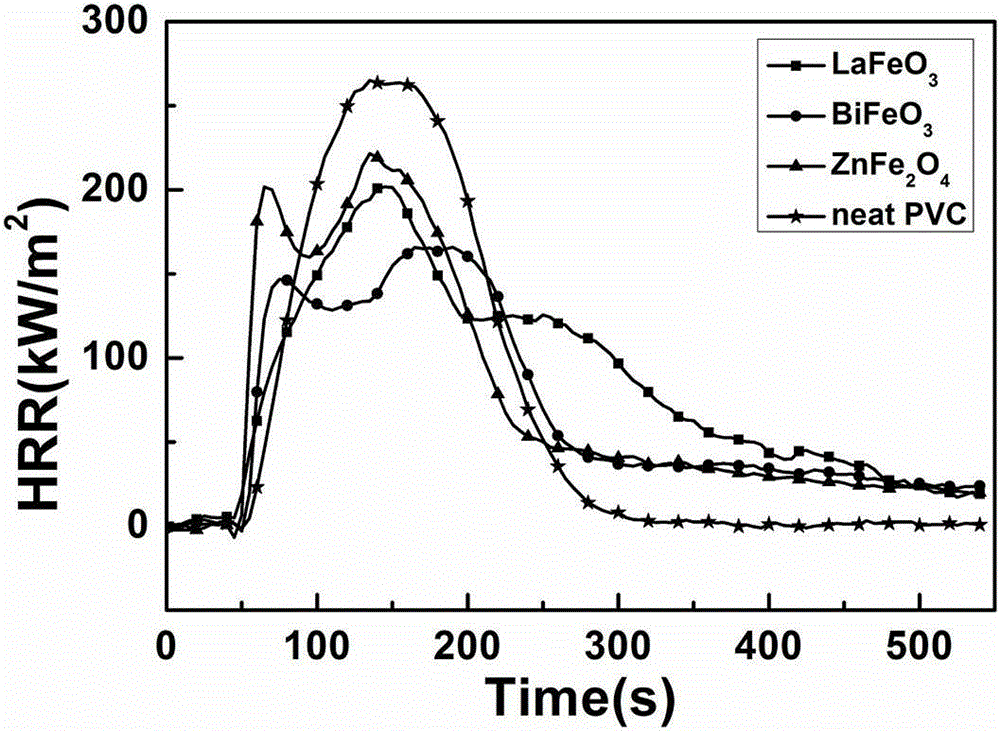

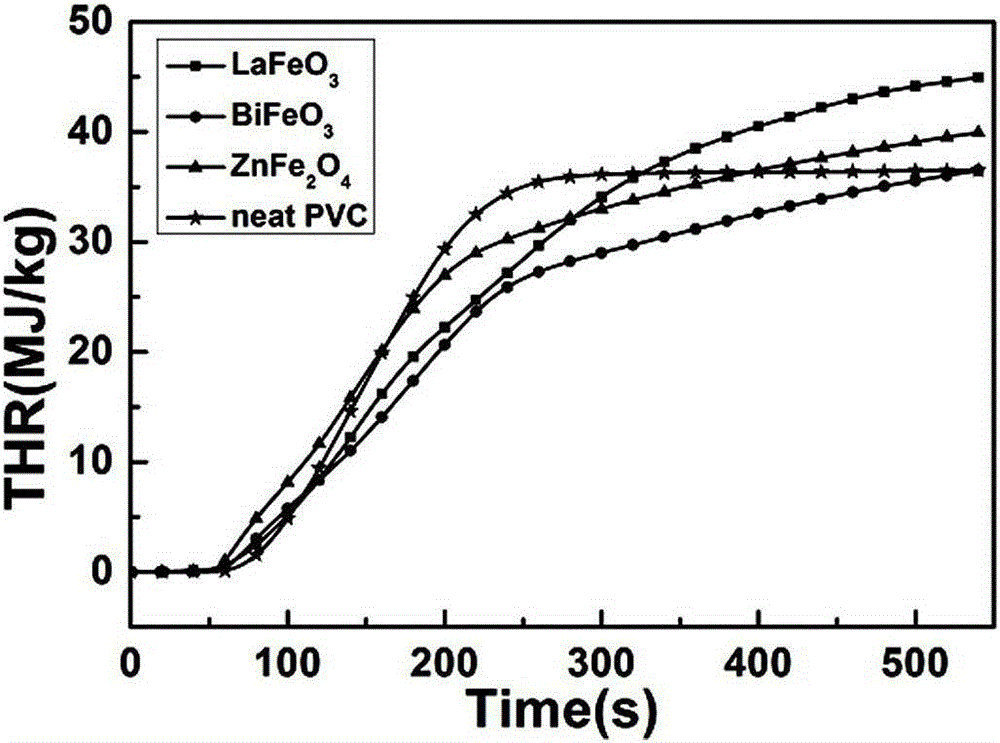

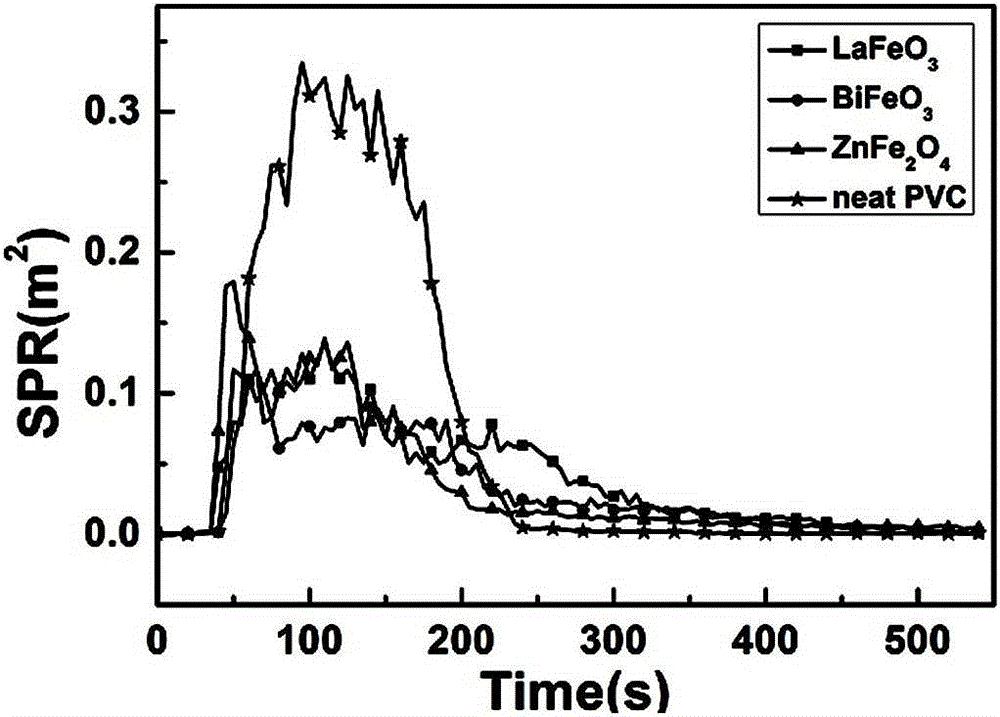

[0028] (3) Put the mechanically stirred mixture in step (2) into a twin-screw extruder for melt blending, extrude and granulate. 175°C, 170°C, 170°C, the screw speed is set to 40r / min. The heat release rate, total heat release amount, smoke release rate, and total smoke release amount of the prepared cable materials are as follows: figure 1 , figure 2 , image 3 , Figure 4 shown.

Embodiment 2

[0030] (1) Mix 100g polyvinyl chloride and BiFeO 3 1g and Mg(OH) 2 19g was dried in a blast oven at 80°C for 3 hours;

[0031] (2) The polyvinyl chloride and BiFeO obtained in step (1) 3 Put 40gDOP, 1gNDZ-311, 5g dibutyltin dilaurate, 0.5g stearic acid, 0.5g calcium stearate into a high-speed mixer, mechanically stir and mix evenly;

[0032] (3) Put the mechanically stirred mixture in step (2) into a twin-screw extruder for melt blending, extrude and granulate. 175°C, 170°C, 170°C, the screw speed is set to 40r / min.

Embodiment 3

[0034] (1) Mix 100g polyvinyl chloride and BiFeO 3 3g and Mg(OH) 2 17g was dried in a blast oven at 110°C for 1.5 hours;

[0035] (2) Put the polyvinyl chloride and BiFeO3 obtained in step (1) with 40gDOP, 1gNDZ-311, 5g dibutyltin dilaurate, 0.5g stearic acid, and 0.5g calcium stearate into a high-speed mixer, and mechanically stir well mixed;

[0036] (3) Put the mechanically stirred mixture in step (2) into a twin-screw extruder for melt blending, extrude and granulate. 175°C, 170°C, 170°C, the screw speed is set to 40r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com