Low-smoke flame-retardant polyvinyl chloride cable material and preparation method thereof

A polyvinyl chloride cable, low-smoke flame-retardant technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of large amount of combustion smoke, poor flame-retardant performance, high production cost, etc. The effect of easy operation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Mix 100 g of polyvinyl chloride and smoke suppression flame retardant BiFeO 3 20 g was dried in a blast oven at 100°C for 1 hour;

[0027] (2) The polyvinyl chloride and BiFeO obtained in step (1) 3 Put 40 g DOP, 1 g NDZ-311, 5 g dibutyltin dilaurate, 0.5 g stearic acid, 0.5 g calcium stearate into a high-speed mixer, mechanically stir and mix evenly;

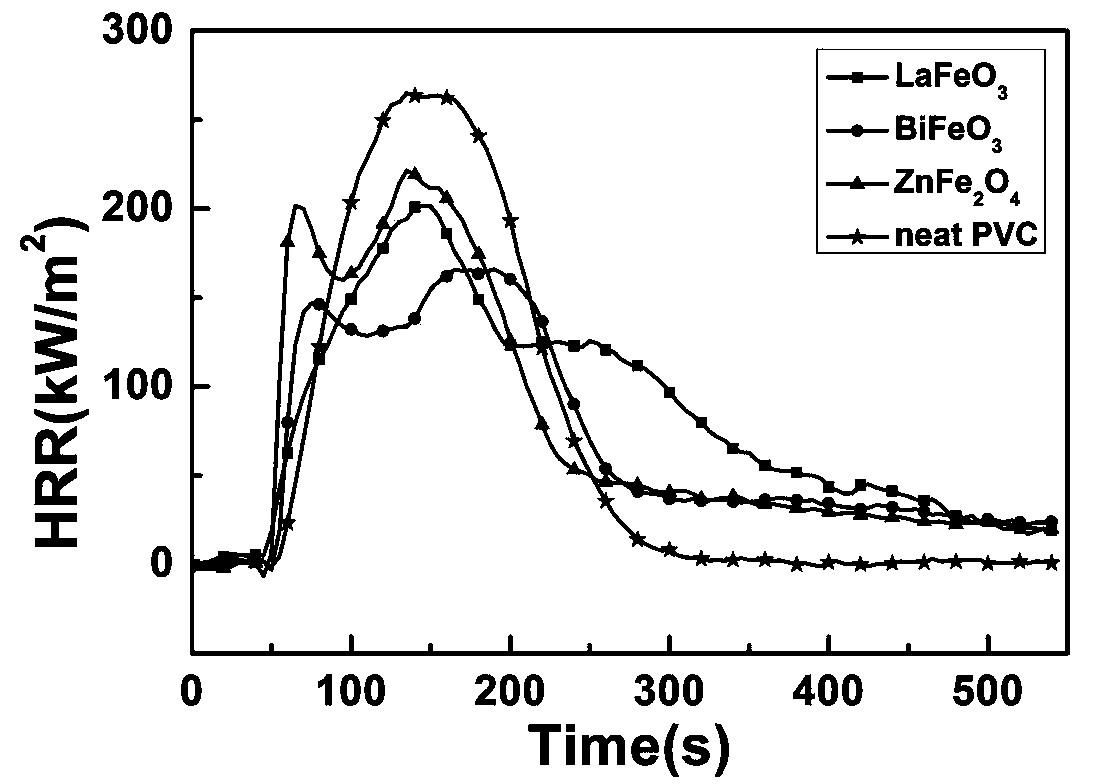

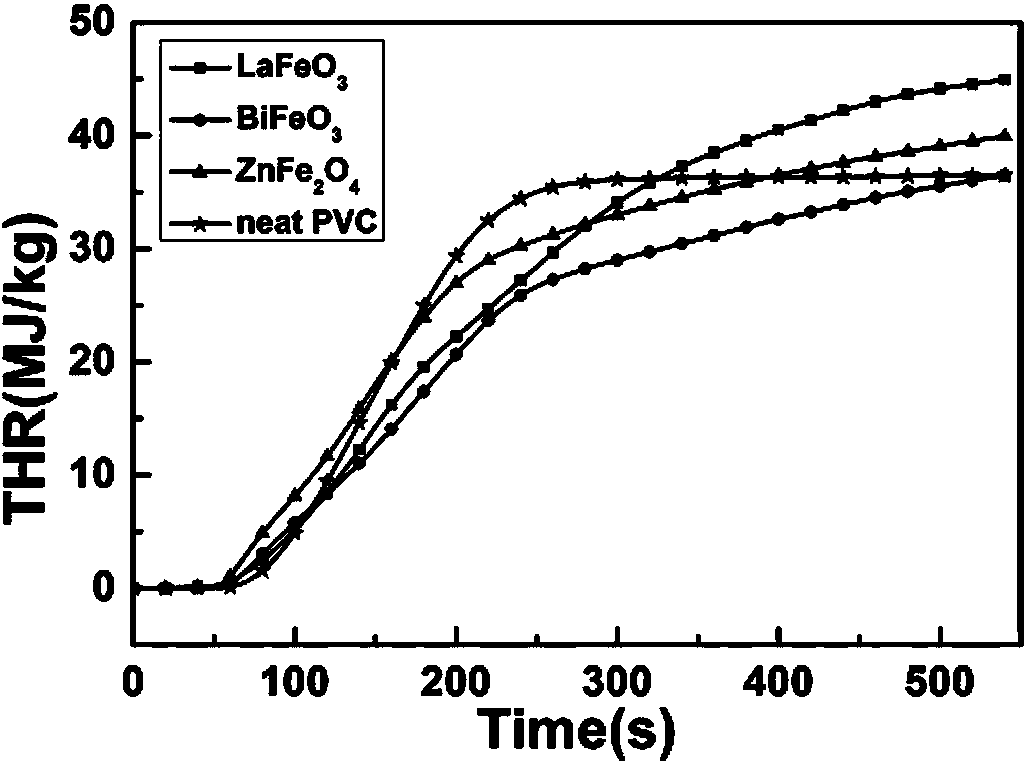

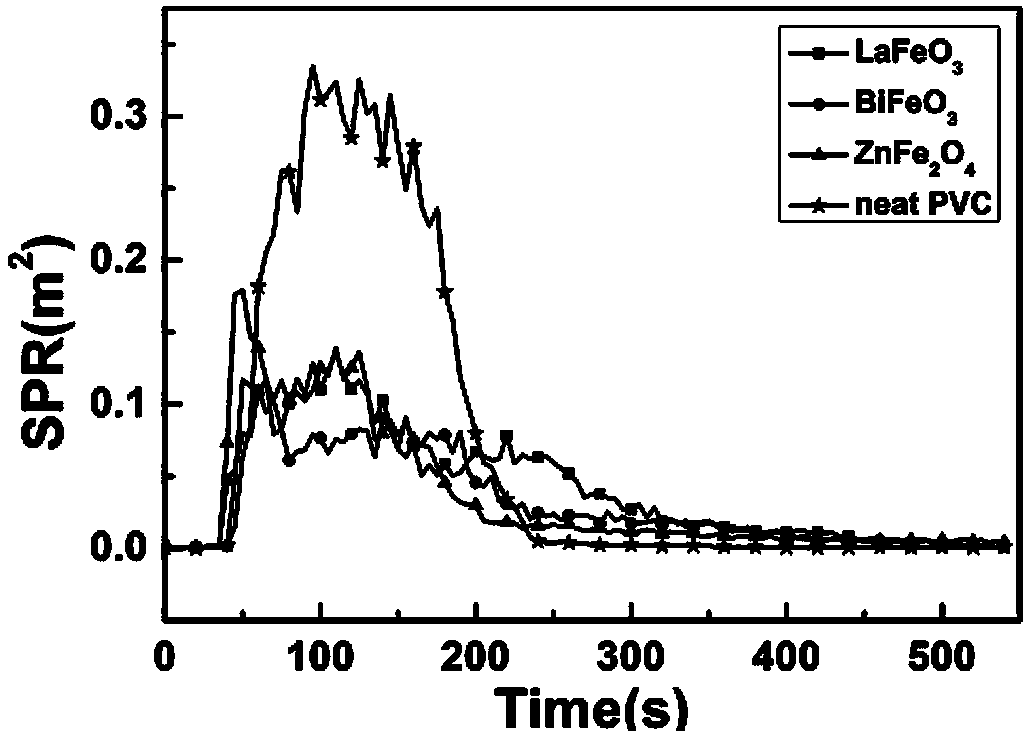

[0028] (3) Put the mechanically stirred mixture in step (2) into a twin-screw extruder for melt blending, extrude and granulate. 175°C, 170°C, 170°C, the screw speed is set to 40 r / min. The heat release rate, total heat release amount, smoke release rate, and total smoke release amount of the prepared cable materials are as follows: figure 1 , figure 2 , image 3 , Figure 4 shown.

Embodiment 2

[0030] (1) Mix 100 g polyvinyl chloride and BiFeO 3 1 g and Mg(OH) 2 19 g was dried in a blast oven at 80°C for 3 hours;

[0031] (2) The polyvinyl chloride and BiFeO obtained in step (1) 3 Put 40 g DOP, 1 g NDZ-311, 5 g dibutyltin dilaurate, 0.5 g stearic acid, 0.5 g calcium stearate into a high-speed mixer, mechanically stir and mix evenly;

[0032] (3) Put the mechanically stirred mixture in step (2) into a twin-screw extruder for melt blending, extrude and granulate. 175°C, 170°C, 170°C, the screw speed is set to 40 r / min.

Embodiment 3

[0034] (1) Mix 100 g polyvinyl chloride and BiFeO 3 3 g and Mg(OH) 2 17 g was dried in a blast oven at 110°C for 1.5 hours;

[0035] (2) Mix the polyvinyl chloride and BiFeO3 obtained in step (1) with 40 g DOP, 1 g NDZ-311, 5 g dibutyltin dilaurate, 0.5 g stearic acid, and 0.5 g calcium stearate at high speed In the machine, mechanically stir and mix evenly;

[0036] (3) Put the mechanically stirred mixture in step (2) into a twin-screw extruder for melt blending, extrude and granulate. 175°C, 170°C, 170°C, the screw speed is set to 40 r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com