Preparation method for high-purity pitaya pigment

A dragon fruit, high-purity technology, applied in chemical instruments and methods, organic dyes, natural dyes, etc., can solve the problems of limited resources, high production costs, waste of pigment resources, etc., and achieve environmental friendliness, easy operation, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of preparation method of high-purity pitaya pigment, its concrete steps are as follows:

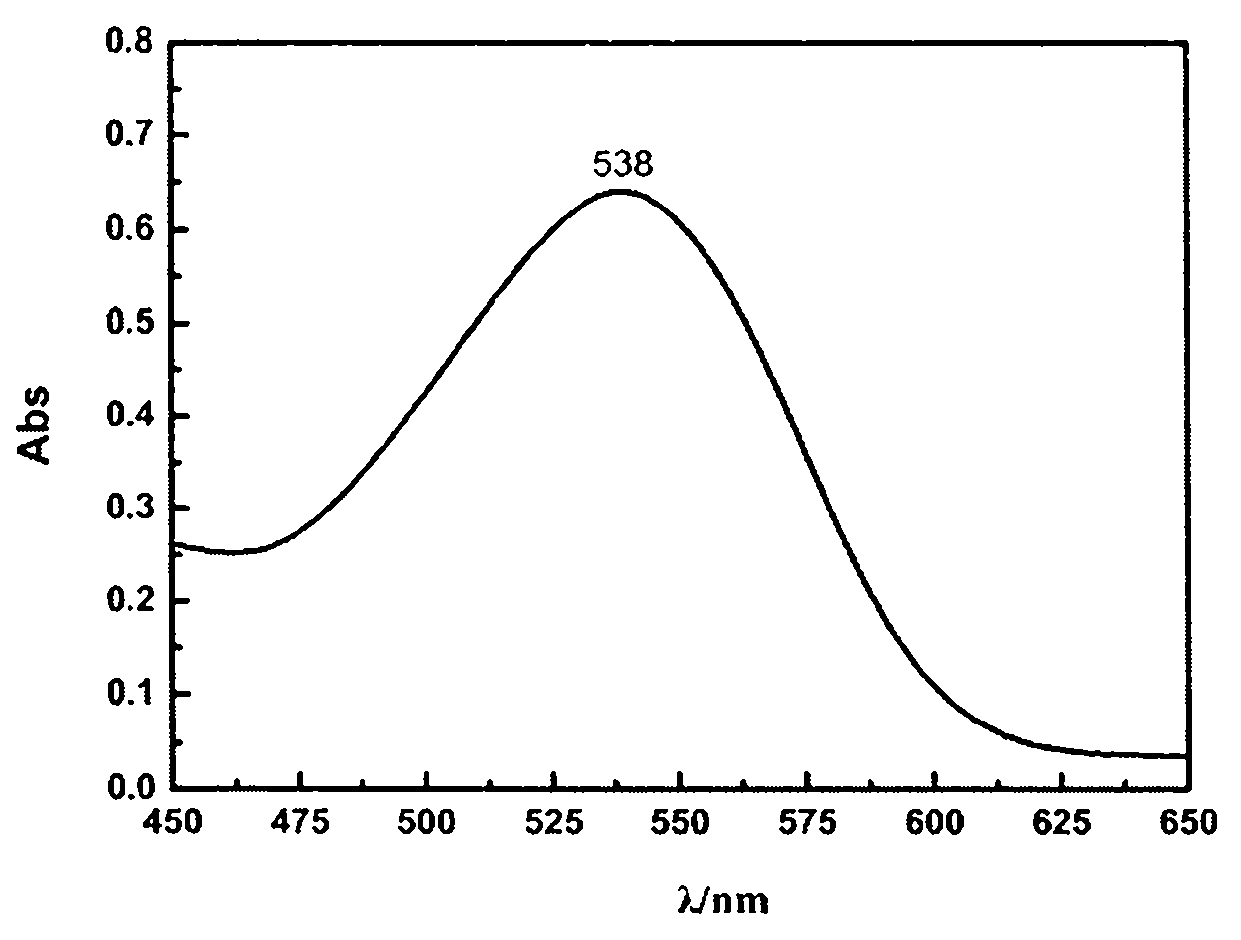

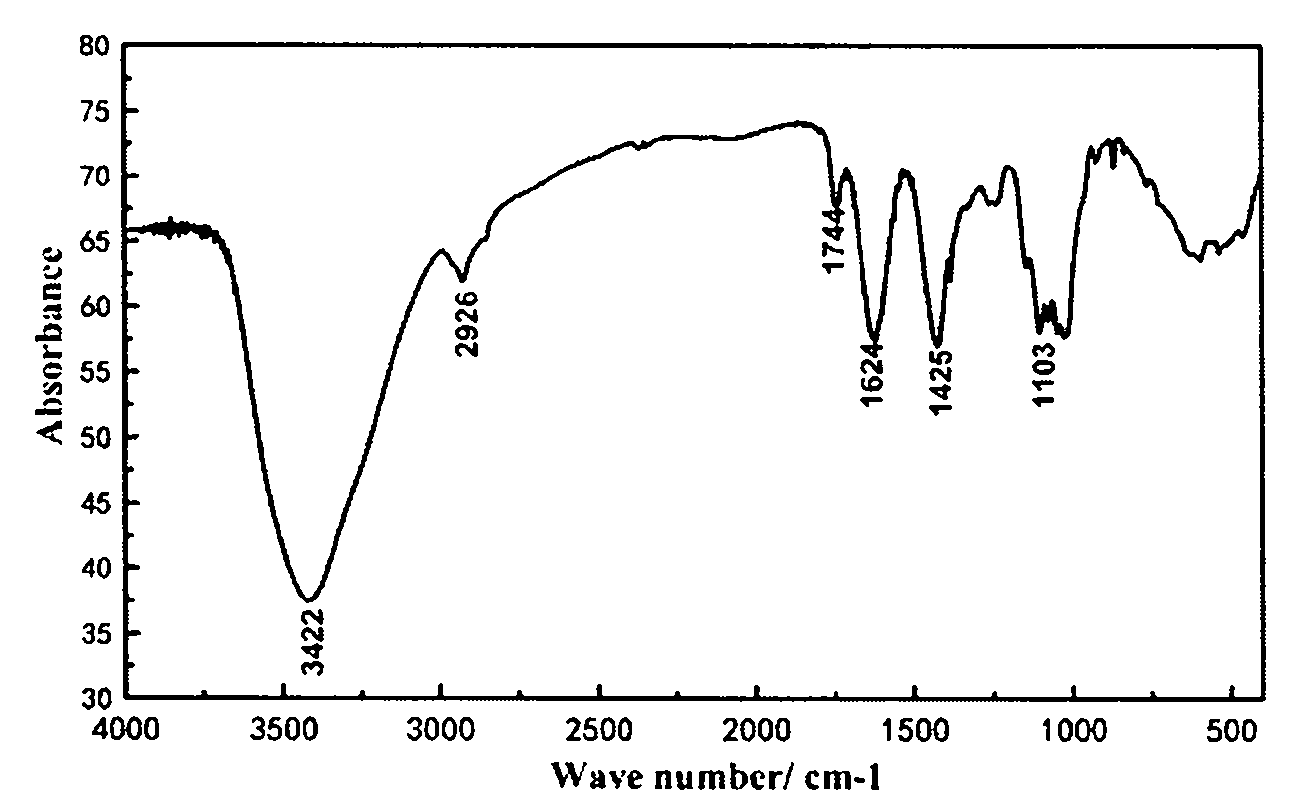

[0027] (1) Ultrasonic-assisted extraction method to prepare the initial extract of pitaya pigment. Wash the pitaya peel, put it in a water bath at 90°C for 30 seconds, take it out, shred it, freeze it at minus 20°C (-20°C) for 1 hour, and weigh it. Take 200g of the material sample and place it in a container with a volume of 1000ml, add 400ml of ethanol solution with a concentration of 40% by volume, and use a frequency of 40kHz ultrasonic assisted leaching for 45min to obtain a purple-red primary infusion.

[0028] (2) Purification of dragon fruit pigment initial infusion

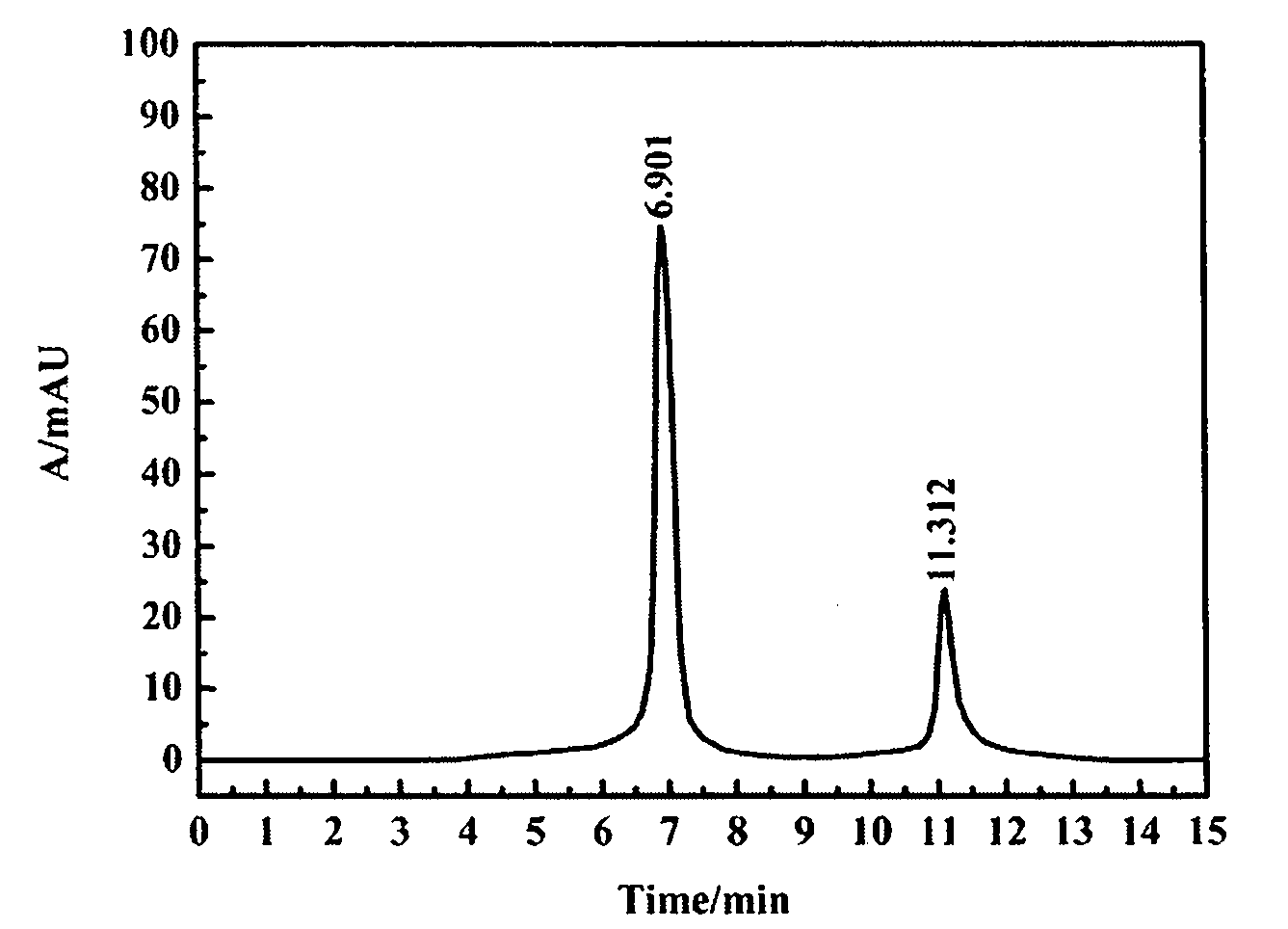

[0029] Use the particle size of the extract in step (1) Suction filtration with a microporous membrane to obtain a clear purple solution; vacuum rotary evaporation at 40°C for 20 min to recover ethanol; mix the clear purple solution with petroleum ether at a volume ratio of 1:3, oscillate and separate,...

Embodiment 2

[0033] A preparation method of high-purity dragon fruit pigment. With embodiment 1, wherein:

[0034] In step (1), the ethanol volume percentage concentration is 30%, and the ultrasonic-assisted extraction time is 35min.

[0035] In step (2), the clear purple red solution was mixed with petroleum ether at a volume ratio of 1:2, the extraction was repeated 3 times, and vacuum rotation was performed at 35°C for 30 min.

[0036] In the (3) step, the deionized water was changed every 3 hours during dialysis, and the color value was measured.

Embodiment 3

[0038] A preparation method of high-purity dragon fruit pigment. With embodiment 1, wherein:

[0039] In step (1), the ethanol volume percentage concentration is 50%, and the ultrasonic-assisted extraction time is 55 min.

[0040] In step (2), the clear purple red solution was mixed with petroleum ether at a volume ratio of 1:4, the extraction was repeated 5 times, and vacuum rotation was performed at 55° C. for 20 minutes.

[0041] In the (3) step, the deionized water is changed every 5h during dialysis, and the color value is measured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com