Clean fracturing fluid suitable for construction in low temperature environment and preparation method thereof

A technology for clean fracturing fluid and low-temperature environment, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of increasing fracturing construction costs, failing to meet the needs of fracturing reconstruction, and increasing construction risks, etc. Achieve the effect of low cost, maximum effect and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

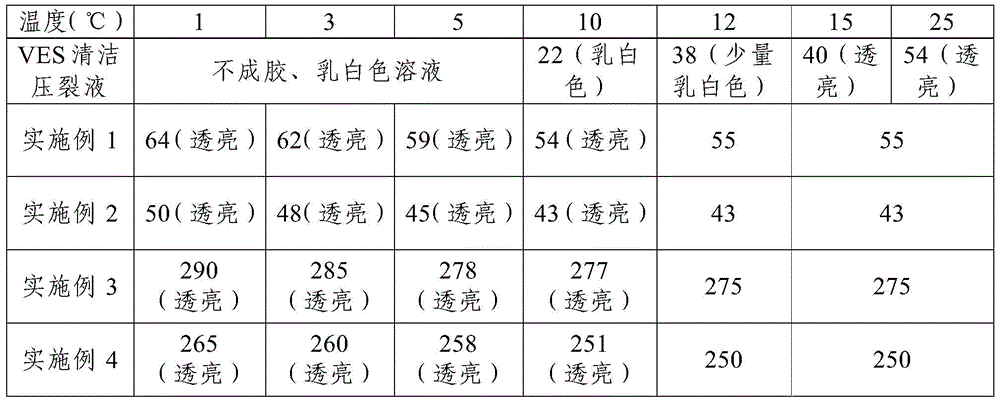

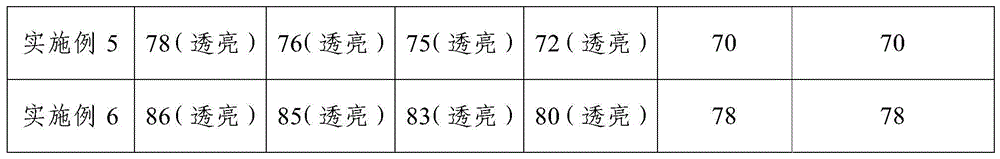

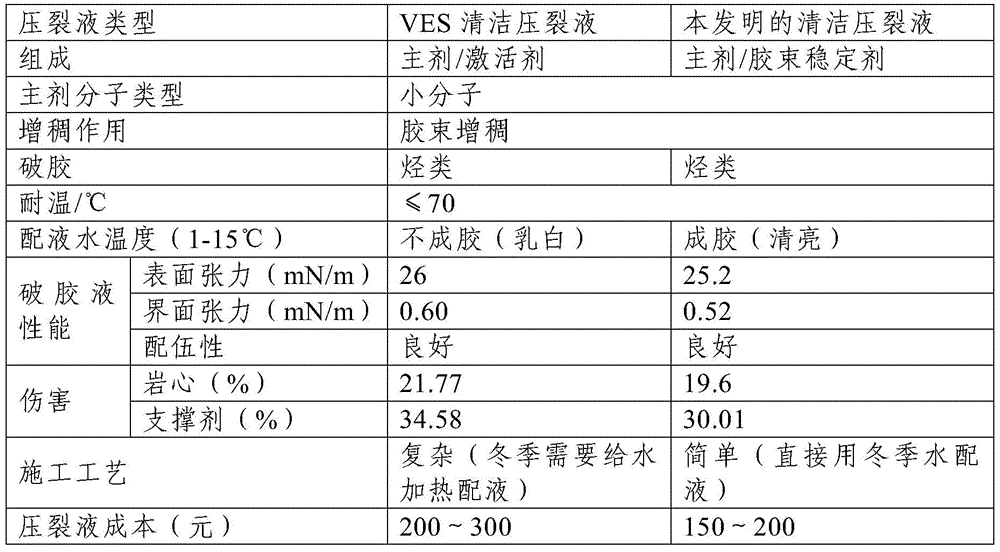

Examples

Embodiment 1

[0017] The clean fracturing fluid suitable for construction in a low temperature environment in this embodiment is made by mixing the fracturing fluid main agent, KCl and water and stirring evenly, wherein the mass of the fracturing fluid main agent accounts for 1.5% of the clean fracturing fluid mass , the quality of KCl accounts for 0.5% of the clean fracturing fluid mass; the main agent of the fracturing fluid is made of the following raw materials in mass percentage: 50% of alkyl dihydroxyethyl methyl ammonium chloride, 3% of micellar accelerator , 20% organic solvent, 0.5% complexing agent, 1% pH regulator, 1% micelle stabilizer, and the balance is water; the alkyl dihydroxyethyl methyl ammonium chloride is C 10 Alkyl dihydroxyethyl methyl ammonium chloride, the complexing agent is EDTA, the micelle accelerator is o-hydroxybenzoic acid, the organic solvent is ethylene glycol, and the pH regulator is sodium carbonate, The micelle stabilizer is cocamidopropyl hydroxysultain...

Embodiment 2

[0022] The clean fracturing fluid suitable for construction in a low temperature environment in this embodiment is made by mixing the fracturing fluid main agent, KCl and water and stirring evenly, wherein the mass of the fracturing fluid main agent accounts for 1% of the clean fracturing fluid mass , the quality of KCl accounts for 0.5% of the clean fracturing fluid mass; the main agent of the fracturing fluid is made of the following raw materials in mass percentage: 70% of alkyl dihydroxyethyl methyl ammonium chloride, 5% of micellar accelerator , 10% organic solvent, 0.1% complexing agent, 0.1% pH regulator, 8% micelle stabilizer, and the balance is water; the alkyl dihydroxyethyl methyl ammonium chloride is C 12 Alkyl dihydroxyethyl methyl ammonium chloride, the complexing agent is triethanolamine, the micelle accelerator is sodium o-hydroxybenzoate, the organic solvent is propylene glycol, and the pH regulator is sodium carbonate, so The micelle stabilizer is lauryl amid...

Embodiment 3

[0027] The clean fracturing fluid suitable for construction in a low temperature environment in this embodiment is made by mixing the fracturing fluid main agent, KCl and water and stirring evenly, wherein the quality of the fracturing fluid main agent accounts for 4% of the clean fracturing fluid mass , the quality of KCl accounts for 2% of the clean fracturing fluid quality; the main agent of the fracturing fluid is made of the following raw materials in mass percentage: 60% of alkyl dihydroxyethyl methyl ammonium chloride, 3.5% of micellar accelerator , 15% organic solvent, 5% complexing agent, 4% pH regulator, 6% micelle stabilizer, and the balance is water; the alkyl dihydroxyethyl methyl ammonium chloride is C 16 Alkyl dihydroxyethyl methyl ammonium chloride, the complexing agent is EDTA, the micelle accelerator is sulfobenzoic acid, and the organic solvent is ethylene glycol and propylene glycol (mass ratio 2:1), The pH regulator is sodium carbonate, and the micelle sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com