Saline soil conditioner

A soil conditioner and salinization technology, applied in soil conditioning materials, organic fertilizers, fertilizer mixtures, etc., can solve the problems of ineffective soil pH value improvement, low cost, and high improvement efficiency, so as to improve microbial activity and ensure Ecological safety and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

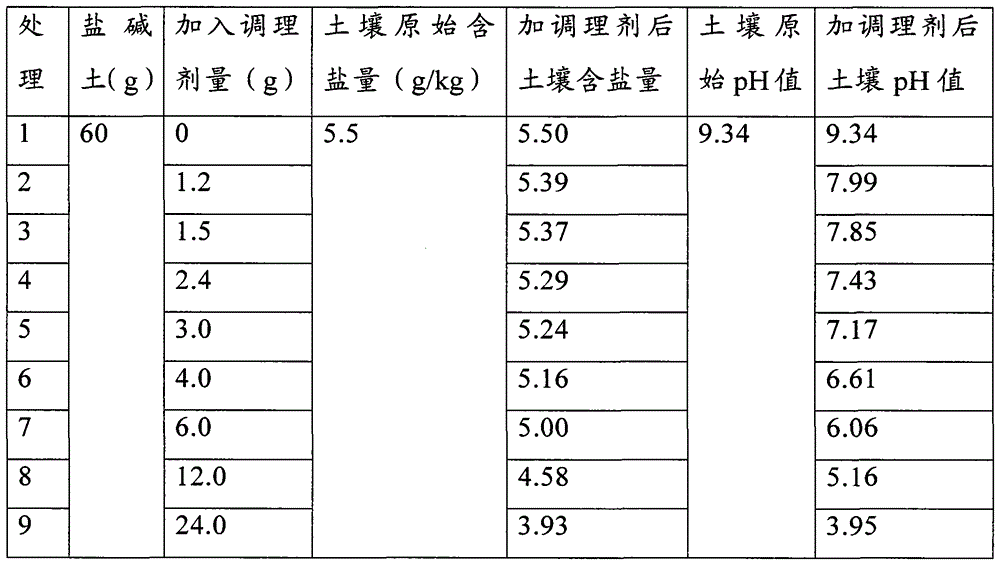

[0071] Embodiment one: conditioning the saline soil for planting tomato

[0072] In the embodiment of the present invention, the higher the salt content of the saline soil and the higher the pH value, the higher the weight percentage of sorrel. The salt content of the saline soil is determined to be 1.8g / kg, and the pH value is 7.6, so the proportioning of the saline soil conditioner applied to the tomato rhizosphere can be: 30% of sorrel dried at low temperature, crushed soybean stalk 55%, 5% straw biochar and 10% wheat bran made under the condition of 500°C. In the specific application, it is applied in holes before the transplanted tomato seedlings, and the saline soil conditioner is applied according to 50kg / mu. After applying the saline soil conditioner according to the embodiment of the present invention, compared with the control group without applying the saline soil conditioner, the single fruit weight of tomato increased by 37g, and the fruit firmness increased by 0...

Embodiment 2

[0073] Embodiment two: conditioning the saline soil for planting cotton

[0074] The saline soil salinity measured in the cotton field is 2.3g / kg, and the pH value is 8.2. The ratio of the saline soil conditioner applied to the cotton rhizosphere is: 38% of sorrel dried at low temperature, crushed soybean 40% of straw, 10% of straw biochar and 12% of wheat bran made under the condition of 500°C. The specific application method is: apply in strips before cotton sowing (tomatoes are transplanted seedlings, one hole and one seedling when transplanted, suitable for hole application, cotton is sown, so strips are applied), and the salt is applied according to 70kg / mu. soil conditioner. After using the saline soil conditioner of the embodiment of the present invention, compared with the control group without using the saline soil conditioner, the cotton bolls shedding decreased, the single boll weight increased by 0.31g, the cotton linter length increased by 0.28mm compared with th...

Embodiment 3

[0075] Embodiment three: conditioning the saline soil for planting sunflower fields

[0076] It is 3.8g / kg to measure the saline soil salinity of planting sunflower field, and the pH value is 8.9. 35% of soybean straw, 10% of straw biochar made under the condition of 500°C, and 10% of wheat bran. The specific application method is: apply the saline soil conditioner at the rate of 60kg / mu before planting the sunflower, and apply it once in the root hole at the budding stage of the sunflower, and apply the saline soil conditioner at 30kg / mu, two times. A total of 90kg / mu was applied each time (the salt content of the sunflower field is high, and the pH value is also relatively large. Applying twice can better ensure the action and effect of the conditioner. The key growth period of the salt-resistant sunflower production is mainly the seedling stage and the budding stage. It is scheduled to be applied at this time, which is conducive to the high yield of sunflower). After appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com