Flexible supporting device and flexible supporting pieces of photoetching machine

A technology of flexible support and lithography machine, which is applied in photoplate-making process exposure devices, microlithography exposure equipment, non-rotational vibration suppression, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

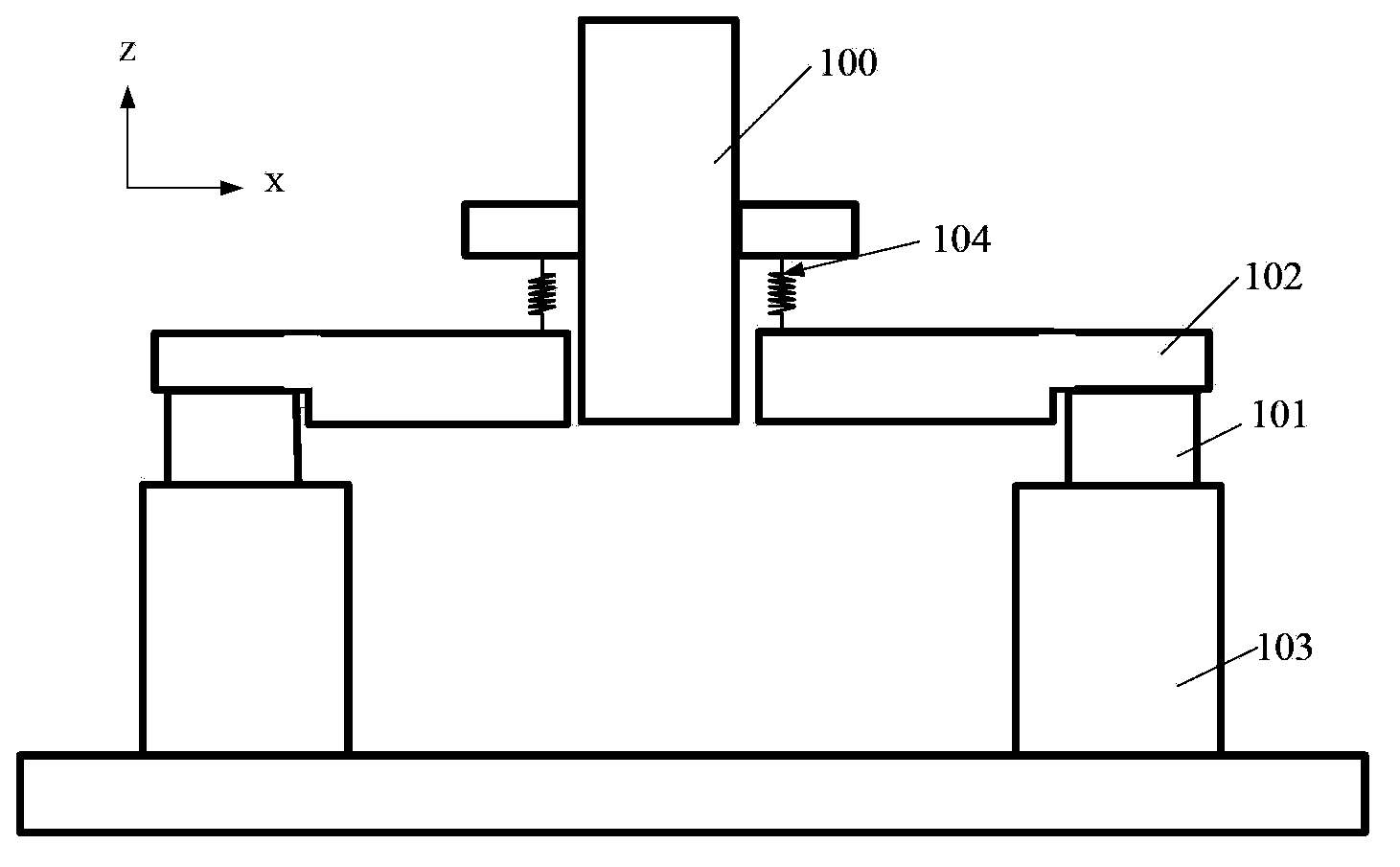

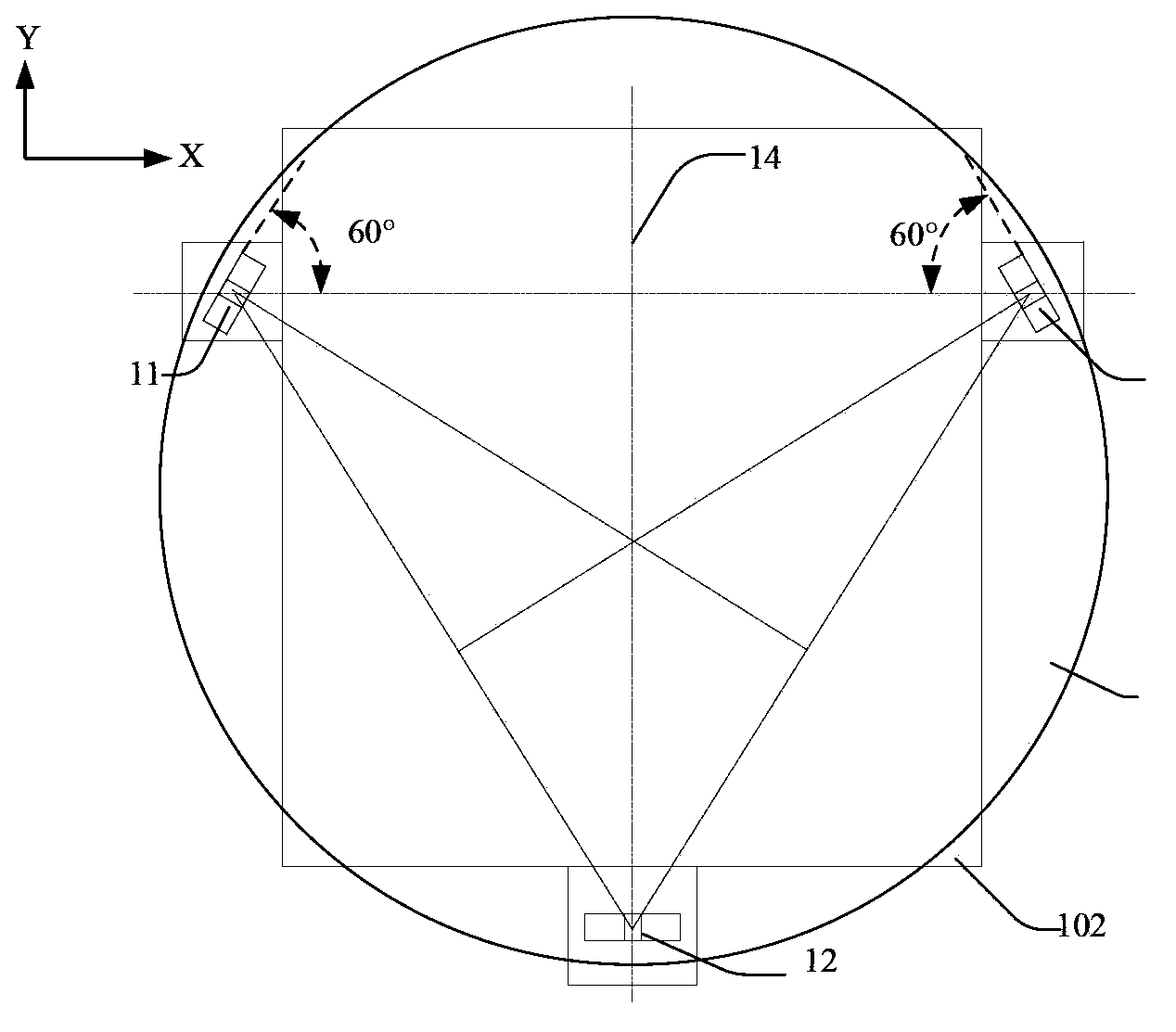

[0056] Such as image 3 As shown, the flexible support device of the present invention includes a first flexible support 11, a second flexible support 12 and a third flexible support 13, the three are distributed at three intersection points of an isosceles triangle, and the first flexible support 11 Located at the apex, the second flexible support 12 and the third flexible support 13 are located at two bottom points, and the center of the objective lens 100 coincides with the center of the triangle.

[0057] The first flexible support 11 is arranged laterally, the angle between the second flexible support 12 and the third flexible support 13 and the first flexible support 11 is 60°, the second flexible support 12 and the second flexible support 13 The three flexible supports 13 are arranged in a mirror image with the midline 14 of the apex as the axis.

[0058] Such as Figure 4 As shown, the flexible support device also includes a limit block 15 and a damper 16 correspondi...

Embodiment 2

[0067] Except for the following differences, all the others refer to Example 1.

[0068] Such as Figure 6 As shown, the first flexible support 11 is arranged vertically, and the second flexible support 12 and the third flexible support 13 are parallel to the first flexible support 11 .

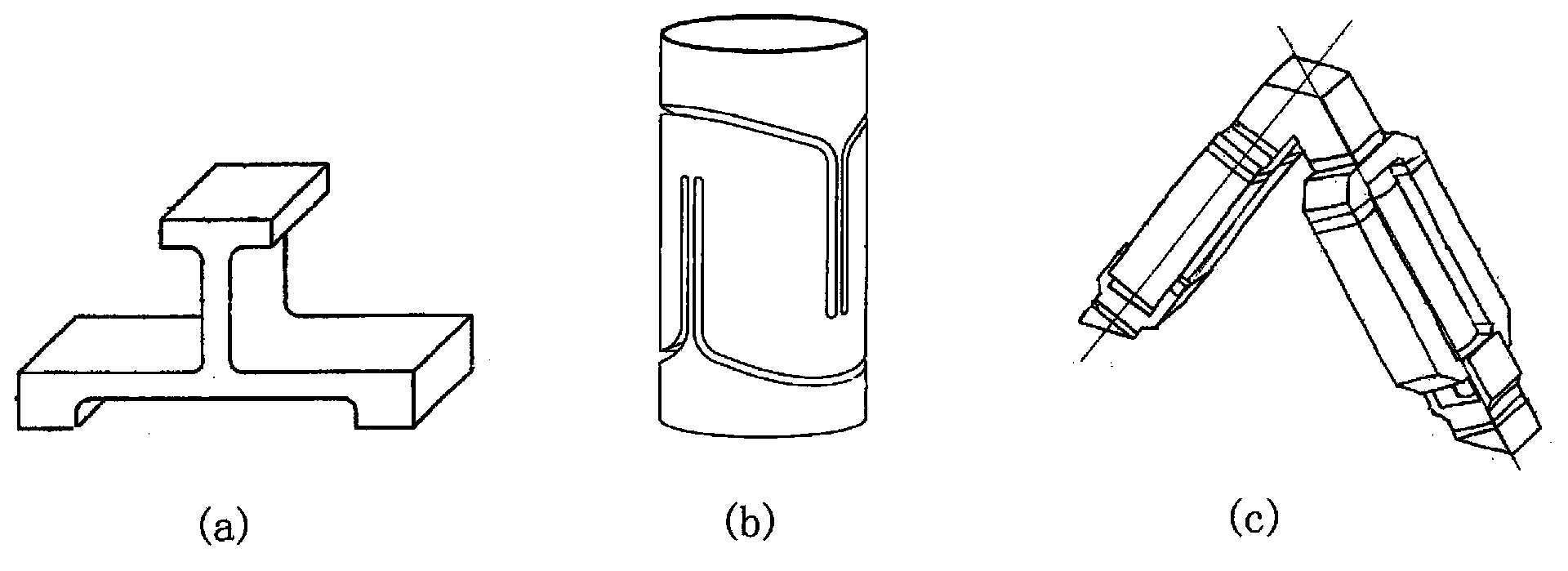

[0069] Such as Figure 7 As shown, the first one-beam 246 in the first flexible connector 24 and the second flexible connector 25 replaces the first cross beam 243, and the second one-beam 247 replaces the second cross beam 245, and the hourglass shape shrinks The section 248 replaces the X-shaped constriction section 241, and a third I-beam 249 is provided at the narrowest point of the hourglass-shaped constriction section 248.

Embodiment 3

[0071] Except for the following differences, all the others refer to Example 1.

[0072] Such as Figure 8 As shown, the first flexible support 11 is arranged horizontally or vertically, and the second flexible support 12 and the third flexible support 13 are perpendicular to the first flexible support 11 . The flexible supporting device does not include the limit block 15 and the damper 16 .

[0073] Such as Figure 9 As shown, the structure of the first flexible support 11, the second flexible support 12 and the third flexible support 13 is the same, taking the first flexible support 11 as an example, it includes a top block 21 connected to the objective lens 100, a flexible The connection mechanism and the first bottom block group 31 and the second bottom block group 32 connected with the main substrate 102 .

[0074] The first bottom block group 31 and the second bottom block group 32 have the same structure, taking the first bottom block group 31 as an example, it incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com