Method for observing inner shearing zone of zirconium base amorphous alloy

A zirconium-based amorphous alloy and shear band technology, which is applied in the preparation of test samples and other directions, can solve the problems of unfavorable shear band formation and evolution research, warping, cracks, curling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

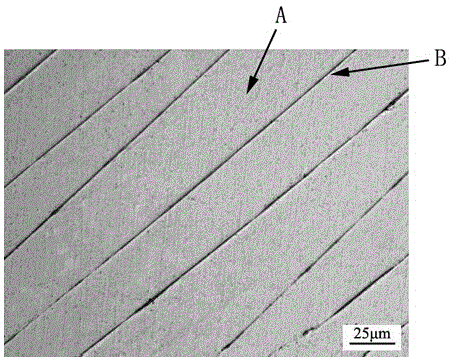

[0017] (1) The zirconium-based amorphous alloy specimen is rolled and deformed by a two-roll rolling mill, and the deformation is 20%;

[0018] (2) Using water as a wetting agent, use 400#, 800#, and 1200# silicon carbide water sandpaper to grind the zirconium-based amorphous alloy specimens plastically deformed in step (1) step by step, and remove the specimens Obtain at least one observation plane for the severely deformed part of the outer surface; each time after changing the sandpaper, turn the observation plane on the specimen 90 degrees in parallel and then grind until the scratches of the previous process are worn away, and each time before changing the sandpaper Clean the specimen with water;

[0019] (3) Place the zirconium-based amorphous alloy specimen ground in step (2) in a polishing machine, and use diamond polishing paste with a particle size of 5 μm and 1 μm to mechanically polish the observation plane of the specimen in sequence;

[0020] (4) Etching the obs...

Embodiment 2

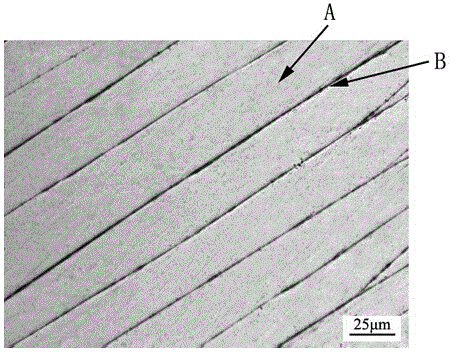

[0023] (1) A zirconium-based amorphous alloy specimen is rolled and deformed by a two-roll rolling mill, and the deformation is 30%;

[0024] (2) Using water as a wetting agent, use 400#, 800#, and 1200# silicon carbide water sandpaper to grind the zirconium-based amorphous alloy specimens plastically deformed in step (1) step by step, and remove the specimens Obtain at least one observation plane for the severely deformed part of the outer surface; each time after changing the sandpaper, turn the observation plane on the specimen 90 degrees in parallel and then grind until the scratches of the previous process are worn away, and each time before changing the sandpaper Clean the specimen with water;

[0025] (3) Place the zirconium-based amorphous alloy specimen ground in step (2) in a polishing machine, and use diamond polishing paste with a particle size of 5 μm and 1 μm to mechanically polish the observation plane of the specimen in sequence;

[0026] (4) Etching the obser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com