Separate lightning protection cable

A separate, cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of conductor heating, dripping, slow production speed, etc., and achieve the effect of reducing the probability of lightning strikes, convenient maintenance, and simple production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

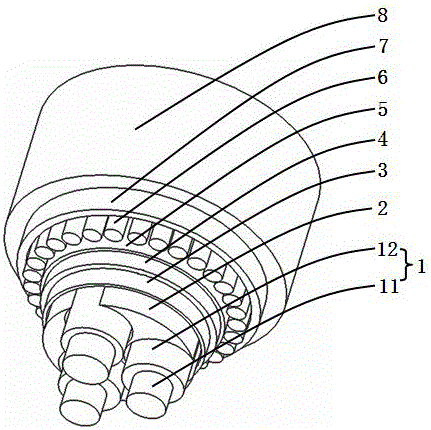

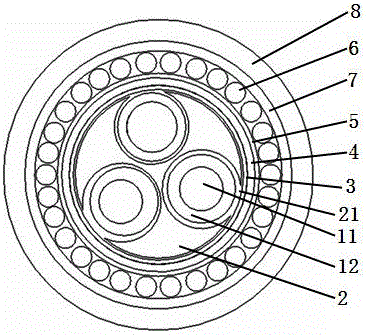

[0034] please see figure 1 and figure 2 , separate lightning protection cable, including three electric units 1, inner sheath 4, armor layer 7, outer sheath 8, and grounding layer 6, the electric unit is composed of a conductor 11 and an insulating layer 12 covering the conductor; the inner The sheath is extruded and coated on the outside of the first protective layer 3, the inner sheath is covered with a second protective layer 5, the grounding layer is located outside the second protective layer, the armored layer is coated on the outside of the grounding layer, and the outer sheath The sleeve is extruded and coated outside the armor layer; the armor layer is a single-sided coated steel tape, and the surface of the armor layer in contact with the ground layer is the non-coated surface; the first protective layer and the second protective layer are both mica Belt; it is characterized in that there is an integrated position fixing element 2 in the first protective layer, and...

Embodiment 2

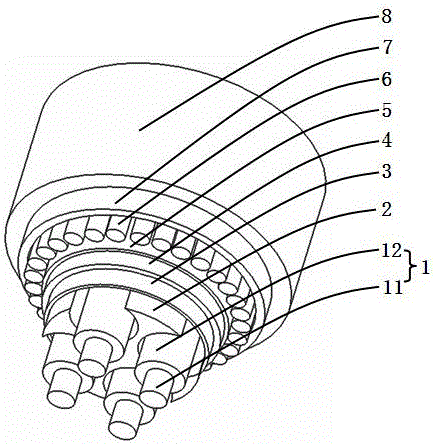

[0036] please see image 3 and Figure 4 , and refer to figure 1 and figure 2 , a separate lightning protection cable, including four electrical units 1, an inner sheath 4, an armor layer 7, an outer sheath 8, and a grounding layer 6. The electrical unit is composed of a conductor 11 and an insulating layer 12 covering the conductor; The inner sheath is extruded and coated on the outside of the first protective layer 3, the inner sheath is covered with the second protective layer 5, the grounding layer is located outside the second protective layer, the armored layer is coated on the outside of the grounding layer, and the outer The sheath is extruded and coated outside the armor layer; the armor layer is a single-sided coated steel tape, and the surface of the armor layer in contact with the ground layer is the non-coated surface; the first protective layer and the second protective layer are both Mica tape; it is characterized in that there is an integrated position fixi...

Embodiment 3

[0038] please see Figure 5 and Figure 6 , and refer to Figure 1 to Figure 4 , The separate lightning protection cable is basically the same as the implementation example 2, except that there is a reinforcing member 9 in the center of the position fixing element.

[0039] Of course, the separate lightning protection cable described in any of the above implementation examples is characterized in that there can be other multiple electric units, and there can be other multiple receiving holes, and the number of electric units is not greater than the number of receiving holes. When the number of electrical units is less than that of the accommodation holes, some of the accommodation holes are empty, and other communication or power transmission media can be placed or reserved.

[0040] The separate lightning protection cable described in any of the above implementation examples is characterized in that the central axes of the plurality of receiving holes are on the same cylind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com