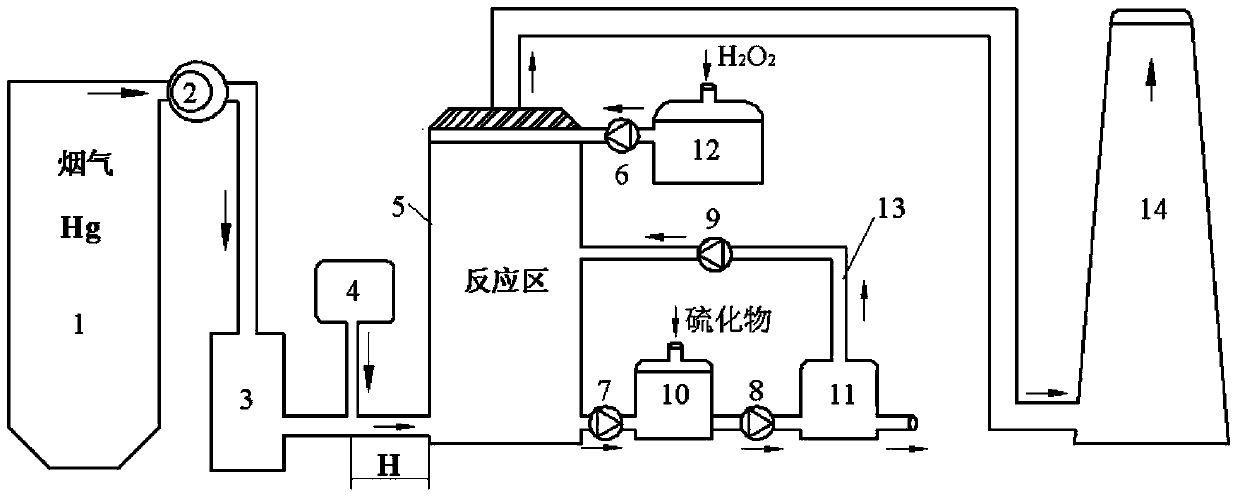

Method and system for removing mercury through free radicals generated based on ozone/hydrogen peroxide

A technology of hydrogen peroxide and free radicals, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc. It can solve the problems of affecting the effective radiation distance of ultraviolet light, deteriorating the long-term operating efficiency of the system, and short penetration distance of ultraviolet light. , to achieve the effects of no secondary pollution, reduced sewage discharge, and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1. Hg in flue gas 0 The concentration is 50 μg / m3, the flue gas temperature is 50°C, the molar concentration of hydrogen peroxide is 1.5mol / L, the ozone injection concentration is 100ppm, and the liquid-gas ratio is 10L / m 3 , the distance between the ozone injection port and the flue gas inlet of the reactor is 50cm. Hg in flue gas 0 The removal efficiency is 89.9%.

Embodiment 2

[0034] Example 2. Hg in flue gas 0 The concentration is 50 μg / m3, the flue gas temperature is 70°C, the molar concentration of hydrogen peroxide is 1.5mol / L, the ozone injection concentration is 100ppm, and the liquid-gas ratio is 10L / m 3 , the distance between the ozone injection port and the flue gas inlet of the reactor is 50cm. Hg in flue gas 0 The removal efficiency is 81.2%.

Embodiment 3

[0035] Example 3. Hg in flue gas 0 The concentration is 100 μg / m3, the flue gas temperature is 50°C, the molar concentration of hydrogen peroxide is 1.5mol / L, the ozone injection concentration is 100ppm, and the liquid-gas ratio is 10L / m 3 , the distance between the ozone injection port and the flue gas inlet of the reactor is 50cm. Hg in flue gas 0 The removal efficiency is 84.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com