Blue and white color porcelain preparation method

A technology for colored porcelain and blue and white porcelain is applied in the field of preparation of blue and white porcelain, which can solve the problems of not being able to control the heat well, affecting the quality of blue and white porcelain, etc., and achieve the effects of bright colors, beautiful styles and simple firing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

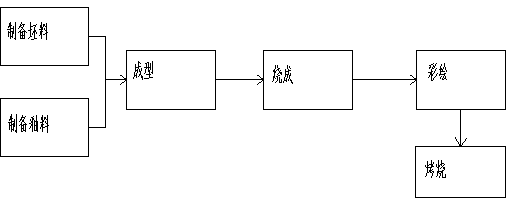

[0006] The following will be further explained according to the flow chart: a preparation method of blue-and-white colored porcelain, which is made by processing technologies such as preparing blanks, molding, firing and painting. The pressed mud cake is rolled into a gypsum mold, and the mold base is put into a chain desiccant or drying room for drying: after the mold base is separated, the green base is dried again, and after reaching a certain strength, it is taken out for trimming; the qualified The green billets are put into kiln car boron plates or gate bowls, bisque fired in the biscuit tunnel kiln, burned with natural gas, plain repaired, polished and washed after leaving the kiln, and then manually or automatically glazed and sprayed on the bisque porcelain after drying. After the glaze is dried again, it is put into a glaze firing tunnel kiln for glaze firing; after the qualified white porcelain is hand-applied, painted and inlaid with gold, it is dried and then put i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com