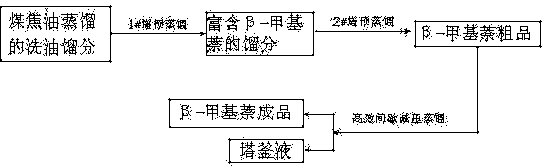

Method for extracting highly pure beta-methylnaphthalene from coal tar wash oil

A technology of methylnaphthalene and coal tar, which is applied in the field of extracting high-purity β-methylnaphthalene, can solve the problems of polluting equipment, complex process, high energy consumption, etc., and achieve the effects of low equipment requirements, convenient and simple operation, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 120tβ-methyl naphthalene content is 27.5wt%, and the indole content is 3.92wt% the wash oil fraction of coal tar distillation as raw material, through continuous pre-distillation, first distilled in 1# pre-distillation tower (1# pre-distillation tower It is a high-efficiency stainless steel packed tower with a packing height equivalent to 60 layers of trays. The top pressure is 5KPa, the top temperature is 220°C, the cutting temperature is 235-255°C, the reflux ratio is 15, and the upper side stream is rich in β-methyl The fraction recovery rate of naphthalene is 39%), obtains β-methylnaphthalene content 69.76wt%, and indole content is the cut 46.8t that is rich in β-methylnaphthalene of 2.79 wt %; The cut is distilled in the 2# pre-distillation tower (2# pre-distillation tower is preferably a high-efficiency stainless steel packed tower with a packing height of more than 80 layers, the preferred pressure at the top of the tower is 5KPa, the effective extraction section ...

Embodiment 2

[0031] With 120tβ-methylnaphthalene content as 28.3wt%, indole content as 4.15wt% coal tar wash oil fraction distillation as raw material, through continuous pre-distillation, first distilled in 1# pre-distillation tower (1# pre-distillation tower It is a high-efficiency stainless steel packed tower with a packing height equivalent to 60 layers of trays. The top pressure is 8KPa, the top temperature is 215°C, the cutting temperature is 230-250°C, the reflux ratio is 20, and the upper side stream is rich in β-methyl The fraction recovery rate of naphthalene is 36%), obtain β-methylnaphthalene content 74.3wt%, indole content is the cut 43.06t that is rich in β-methylnaphthalene of 3.02 wt %; The fraction is distilled in the 2# pre-distillation tower (2# pre-distillation tower is preferably a high-efficiency stainless steel packed tower with a packing height of more than 80 layers, the tower top pressure is preferably 2KPa, the effective extraction section temperature is 242°C, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com