Method for extracting high-purity phenazine from RT base (4-Aminodiphenylamine) byproduct waste material

A high-purity, phenazine technology, applied in the field of phenazine refining, can solve the problems of dull product color, high consumption, disturbing RT production system, etc., and achieve the effect of bright appearance, increased burden, and stable purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

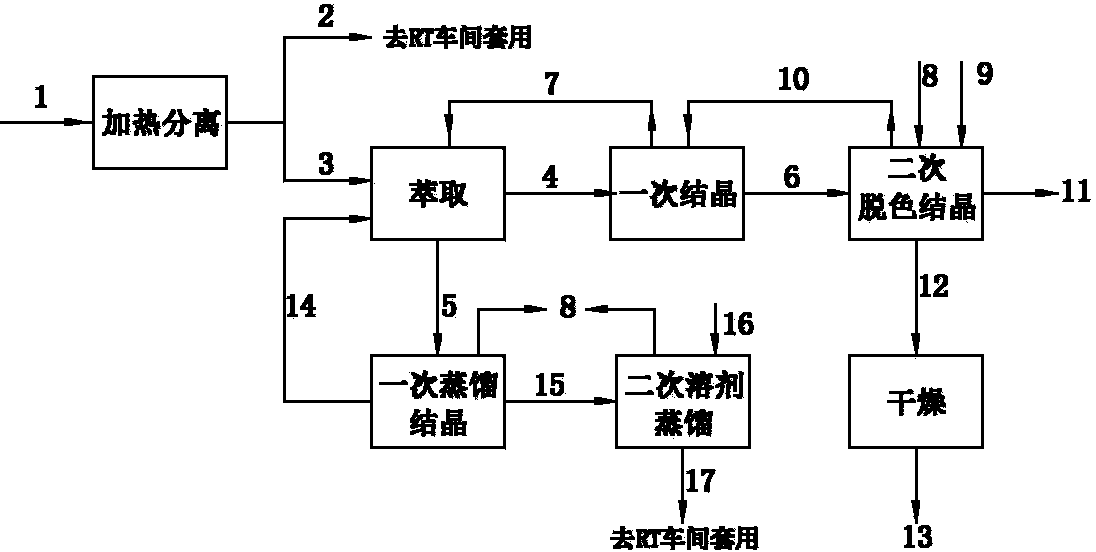

[0031] A method for extracting high-purity phenazine from RT base by-product waste, comprising the steps of:,

[0032] (1), heating separation

[0033] Heat 120g of RT base by-product waste 1 in a water bath to 85°C, filter and separate to obtain liquid phase 2 and crude phenazine 3;

[0034] (2), extraction

[0035] Add all the heated and separated crude phenazine 3 into the primary crystallization mother liquor 7, heat up and reflux for 60 minutes, cool to 25°C, pour into a funnel for filtration, and obtain the extraction mother liquor 5 and the extraction phenazine 4;

[0036] (3), primary crystallization

[0037] Add all the extracted phenazine 6 to the secondary decolorization crystallization mother liquor 10, heat up and reflux for 50 minutes, cool to 25°C, pour into a funnel for filtration, and obtain the primary crystallization mother liquor 7 and the primary crystallization phenazine 6;

[0038] (4), secondary decolorization crystallization

[0039] The primary cr...

Embodiment 2

[0048] A method for extracting high-purity phenazine from RT base by-product waste, comprising the steps of:,

[0049] (1), heating separation

[0050] The crude phenazine 14 obtained in Example 1 was heated and melted together with 120 g of RT base by-product waste at 100° C., and the liquid phase and solid-phase crude phenazine with higher phenazine content were separated;

[0051] (2), extraction

[0052] Add the solid-phase crude phenazine obtained by heating and separating in step (1) to the primary crystallization mother liquor 7 obtained in Example 1, heat up and reflux for 30-60 minutes, and cool to 20°C-30°C for solid-liquid separation to obtain the extract mother liquor and extract phenazine;

[0053] (3), primary crystallization

[0054] Add the extracted phenazine obtained in step (2) to the secondary decolorization crystallization mother liquor 10 obtained in Example 1, stir and raise the temperature and reflux for 40-70 minutes, then cool to 20°C-30°C for soli...

Embodiment 3

[0065] A method for extracting high-purity phenazine from RT base by-product waste, comprising the steps of:,

[0066] (1), heating separation

[0067] The crude phenazine 14 obtained in Example 2 was heated and melted together with 120 g of RT base by-product waste at 100° C., and the liquid phase and solid phase crude phenazine with higher phenazine content were separated;

[0068] (2), extraction

[0069] Add the solid-phase crude phenazine obtained by heating and separating in step (1) to the primary crystallization mother liquor obtained in Example 2, heat up and reflux for 30-60 minutes, cool to 20°C-30°C for solid-liquid separation, and obtain the extract mother liquor and extract phenazine Zinc;

[0070] (3), primary crystallization

[0071] Add the extracted phenazine obtained in step (2) to the secondary decolorization crystallization mother liquor obtained in Example 2, stir and raise the temperature and reflux for 40-70 minutes, then cool to 20°C-30°C for solid-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com