Polyether modified alkoxy silane containing organo-functional group and manufacute method for the same

An organosiloxane, alkoxysilane technology, applied in textiles and papermaking, coatings, adhesives, etc., can solve the problems of reduced reactivity, no co-modification, and intolerant of use, and achieves inhibition of coloration and residue. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

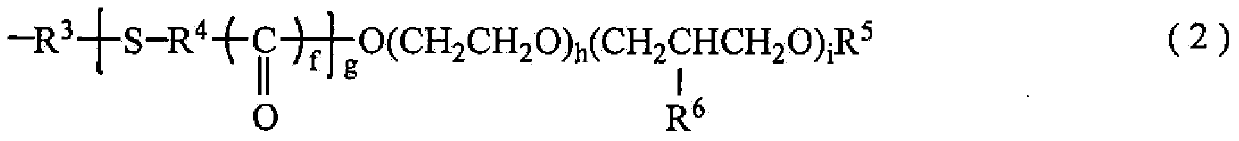

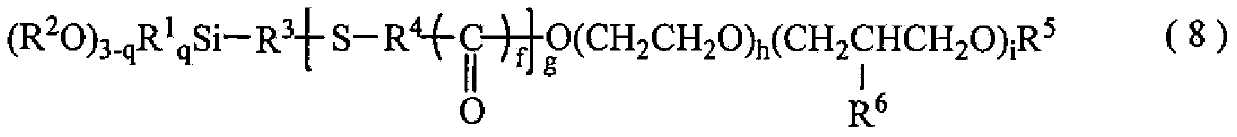

Method used

Image

Examples

Embodiment 1

[0162] [Example 1] (Synthesis of polyether-modified methoxysiloxane containing mercapto group-1)

[0163] 25.0 g of 3-mercaptopropyl trimethoxysilane (12.7 × 10 -2 mol), 28.8g (4.25×10 -2 mol) and diacetone alcohol 17.0g, 2.67g of 0.05N hydrochloric acid aqueous solution (water: 14.8×10 -2 mol, hydrochloric acid: 1.34×10 -4 mol), and then matured for 2 hours.

[0164] (CH 3 O) 3 Si-C 3 h 6 -O(CH 2 CH 2 O) 11 CH 3 (19)

[0165] Next, add 1.91 g of a 1% methanol solution of sodium acetate (sodium acetate: 2.33×10 -4 mol), the temperature was raised to 70°C for 2 hours of aging.

[0166] Next, heating under reduced pressure at 100° C. and 10 mmHg for 2 hours, distilled off residual alcohol components and low boiling point components, and filtered to obtain a liquid organosiloxane 1 with a non-volatile content of 99.0% (yield: 42.7g, yield: 91%).

[0167] In this organopolysiloxane 1, in the above-mentioned average composition formula (1), Y is a 3-mercaptoprop...

Embodiment 2

[0170] [Example 2] (Synthesis of polyether-modified methoxysiloxane containing mercapto group-2)

[0171] 12.5 g of 3-mercaptopropyl trimethoxysilane (6.36 × 10 -2 mol) and 35.4g (6.36×10 -2 mol), 0.5 g of PERBUTYL-O [manufactured by NOF Corporation: tert-butyl peroxy-2-ethylhexanoate] was added with stirring, and aging was performed at 65° C. for 2 hours.

[0172] CH 2 =CH-CH 2 -O(CH 2 CH 2 O) 11 CH 3 (twenty three)

[0173] The resulting liquid was subjected to GPC (gel permeation chromatography) measurement in THF solvent. As a result, product peaks were confirmed within the retention time range of 28 minutes to 34 minutes. In addition, the peak derived from 3-mercaptopropyltrimethoxysilane almost disappeared in the retention time range of 36 minutes to 38 minutes. In addition, for the liquid generated above, the 1 H-NMR determination. As a result, the peak derived from the allyl group of the allylated polyether represented by the above formula (23) existin...

Embodiment 3

[0180] [Example 3] (Synthesis of polyether-modified methoxysiloxane containing mercapto group-3)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com