Preparation method of high-temperature inactivation resistant gold-based catalyst for synthesizing chlorethylene

A catalyst, the technology of gold trichloride, which is applied in the field of preparation of high temperature deactivation resistance, can solve the problems of increased deactivation rate and less use of other group substances, so as to improve thermal stability, reduce energy consumption, and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

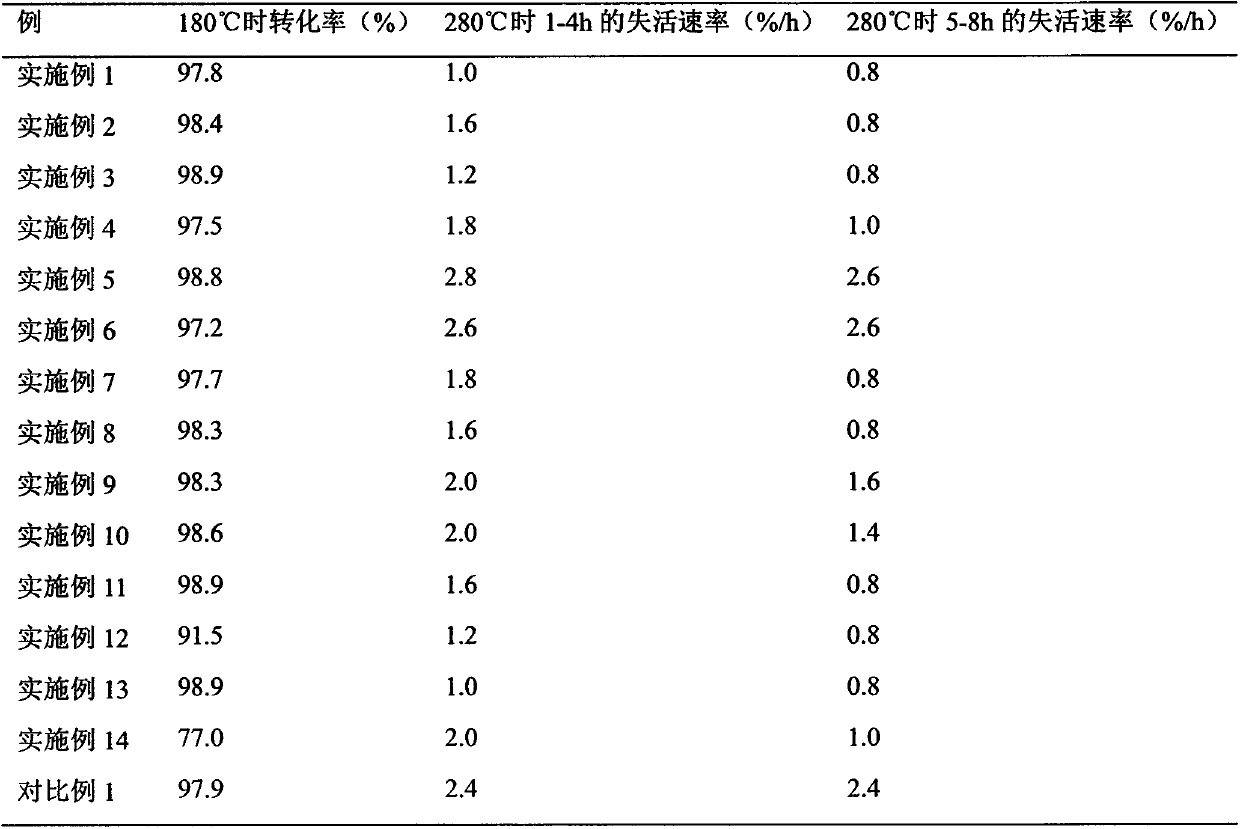

Examples

Embodiment 1

[0071] The first step, the washing of activated carbon:

[0072] At room temperature, weigh 5g of activated carbon and add 50g of water, oscillate under ultrasonic conditions to sink all activated carbon particles under water; pour out the supernatant and then add the same amount of water, and then keep the system for no less than 30s After supersonic treatment, the supernatant was poured out and an equal amount of water was added. This step was repeated three times to obtain sample A.

[0073] The second step, configuration of cysteine solution:

[0074] Under the condition of ultrasonic vibration at room temperature, 0.5 g of cysteine was added to 38.5 g of hydrochloric acid with a concentration of 1.2 mol / L to prepare a cysteine solution.

[0075] The third step, surface modification of activated carbon:

[0076] While stirring at room temperature, add the cysteine solution dropwise to sample A, start timing after the dropwise addition, and after stirring for at l...

Embodiment 2

[0084] Except that in the second step, the mass of cysteine added is 0.1 g, the others are the same as in Example 1.

Embodiment 3

[0086] Except that in the second step, the mass of cysteine added is 0.05g, other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com