Wood pulp nitrocellulose single-base propellant and preparation method thereof

A nitrocellulose and single-base propellant technology is applied in the field of wood pulp nitrocellulose single-base propellant and its preparation, and achieves the effects of stable performance, less impurities and good quality consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] In addition to providing the above-mentioned wood pulp nitrocellulose single-base propellant, the present invention also provides a preparation method of the above-mentioned wood pulp nitrocellulose single-base propellant. It includes the following steps:

[0046] a. Water flooding: water-containing wood pulp nitrocellulose is flooded, and ethanol with a volume concentration of 72% to 100% is sprayed during the water flooding process to obtain wood pulp nitration with a water mass percentage of ≤4.0% and a certain amount of ethanol cellulose;

[0047] b. Plasticization: add 1% to 2% stabilizer and 50% to 110% solvent to the wood pulp nitrocellulose after water displacement in step a, based on the pure dry weight of wood pulp nitrocellulose, and then add 0% to 110% solvent 7% other additional ingredients, plasticized and mixed at -5°C to 35°C for 60min to 120min;

[0048] Wherein, the other additional ingredients described are one or more of potassium nitrate, potassiu...

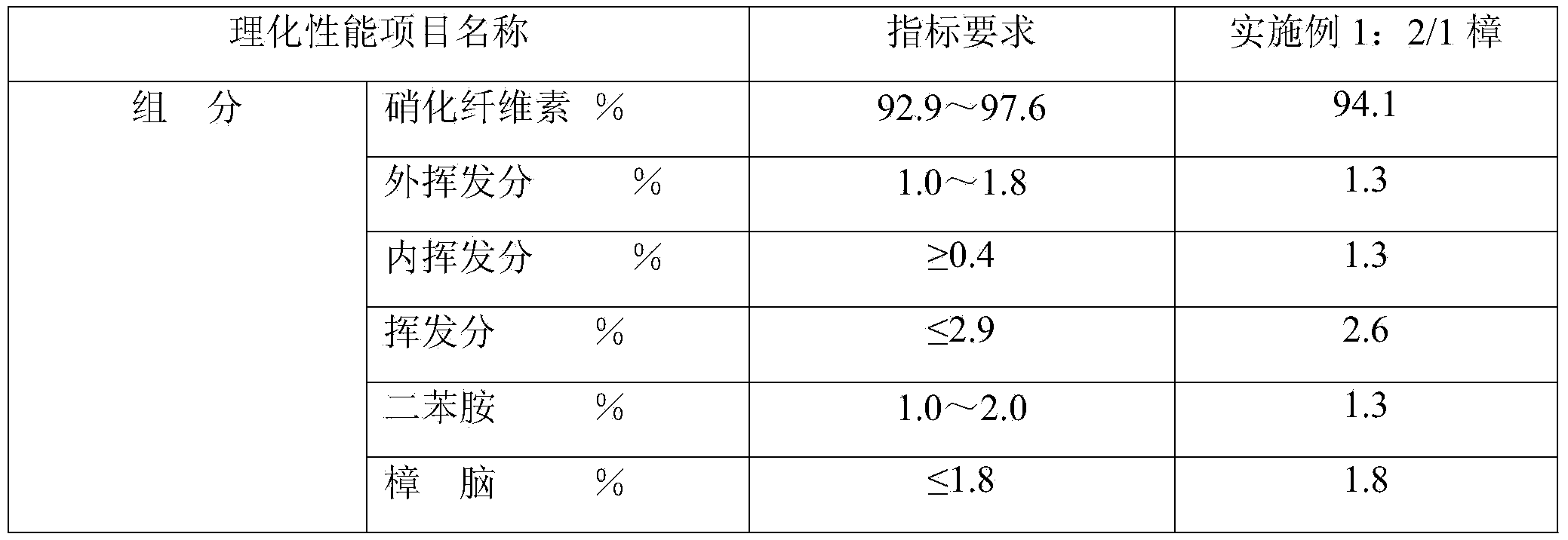

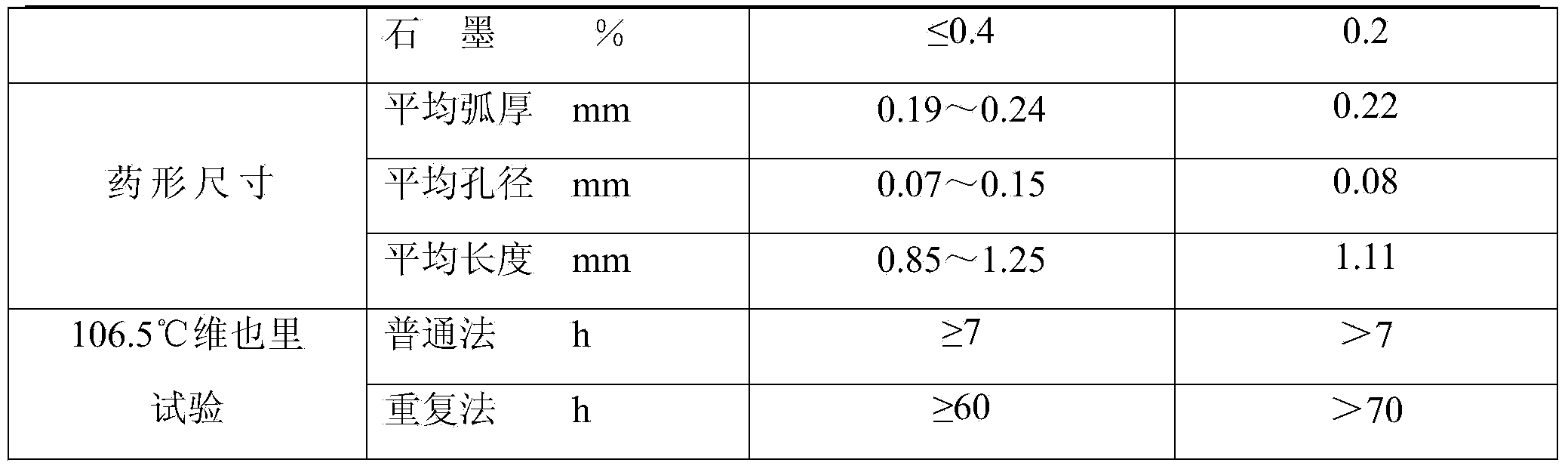

Embodiment 1

[0061] The preparation of wood pulp nitrocellulose single-base propellant 2 / 1 camphor comprises the following steps:

[0062] (1) Water flooding: put the water-containing wood pulp nitrocellulose into the centrifugal water flooding machine, first gradually spray 35L of ethanol with a volume concentration of 72% to 76% in the centrifugal water flooding machine, uniformly flood the water for more than 3min, and then Gradually spray 48L to 53L of ethanol with a volume concentration of 95% to 100%, and drive water for more than 15 minutes to produce water-repelling wood pulp nitrocellulose with a water content of ≤4.0%;

[0063] (2) Plasticization: According to the existing 2 / 1 single-base propellant technology of Zhang product number, the wood pulp nitrocellulose after the water displacement in step a is added to the gelling machine, calculated according to the pure dry weight of wood pulp nitrocellulose , dissolve 1.5% stabilizer diphenylamine in ether, prepare the solution and ...

Embodiment 2

[0069] The preparation of wood pulp nitrocellulose single base propellant 4 / 7 stone comprises the following steps:

[0070] (1) Water flooding: put the water-containing wood pulp nitrocellulose into the centrifugal water flooding machine, first gradually spray 40L of ethanol with a volume concentration of 72% to 76% in the centrifugal water flooding machine, and evenly flood the water for 10 minutes, then Gradually spray 60L of ethanol with a volume concentration of 95% to 100%, and displace water for 20 minutes to obtain water-displacing wood pulp nitrocellulose with a water content of ≤4.0%.

[0071] (2) Plasticization: According to the existing 4 / 7 stone product number single-base propellant technology, take the water-displacing wood pulp nitrocellulose prepared in step (1) and add it to the gelling machine; Calculated, dissolve 1.6% diphenylamine in ether, prepare the solution and then add it to the plasticizing equipment, wherein the amount of ether added is 65% to 80%, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Needle length | aaaaa | aaaaa |

| Needle length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com