Thermosetting composite resin foam insulation board and preparation method thereof

A composite resin and insulation board technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as inability to shape, particle sandwich, and excessive use of flame-retardant adhesives, to ensure fire protection rating, bond The effect of high strength and low smoke volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

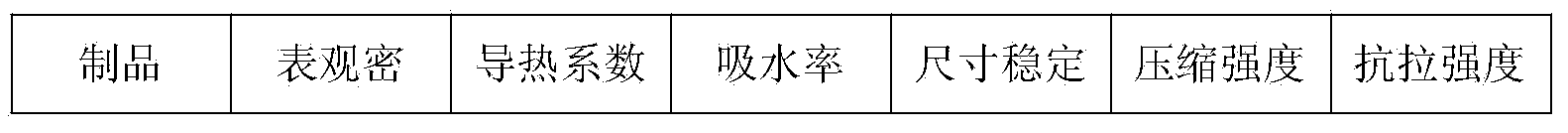

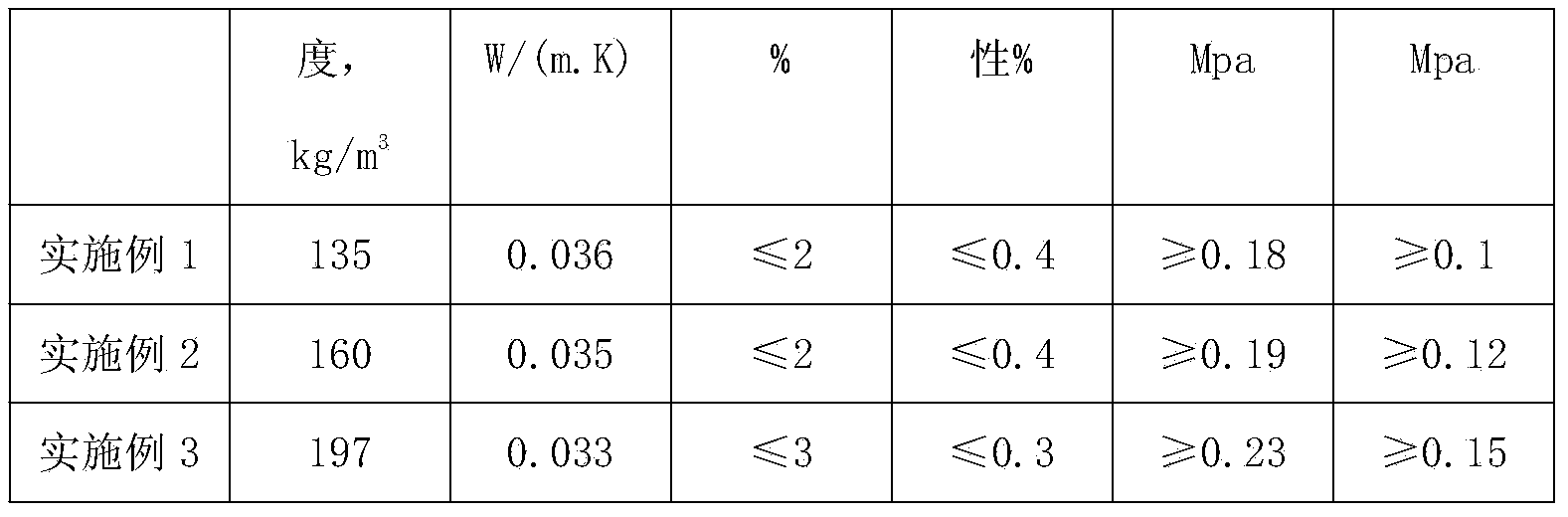

Examples

Embodiment 1

[0028] Preparation of fireproof hybrid adhesive: 1 part of aluminum dihydrogen phosphate, 0.3 part of phenolic resin, 0.1 part of melamine formaldehyde resin, 0.08 part of diisocyanate, 0.1 part of n-pentane, surfactant DC-193 and non-silicone surface Active agent Tween-80 mixed substance 0.02 part;

[0029] The deployment of curing agent: 1 part of zirconia, 1 part of silicon nitride, 8 parts of alumina;

[0030] Coating of EPS foam particles: Take 100g of pre-haired and matured EPS particles, 1000g of fireproof hybrid adhesive, stir evenly, add 100g of curing agent, and continue stirring until uniformly coated EPS particles are obtained; microwave heating and drying Dry for about 0.5min, and dry with hot air for about 1min to obtain gelled EPS particles;

[0031] Compression molding: Put the above-mentioned uniformly coated EPS particles into the mold and pressurize it, place the mold in a heating device with a temperature of about 120°C, keep it for 1-2min, cool down, and ...

Embodiment 2

[0033] Preparation of fireproof hybrid adhesive: 1 part of aluminum dihydrogen phosphate, 0.5 part of phenolic resin, 0.15 part of melamine formaldehyde resin, 0.1 part of diisocyanate, 0.1 part of isopentane, DC-193 and non-silicone surfactant 0.03 parts of mixed substances of Wen-80;

[0034] The deployment of curing agent: 1 part of zirconia, 1 part of silicon nitride, 15 parts of alumina;

[0035] Coating of EPS foam particles: Take 100g of pre-haired and matured EPS particles, 1200g of fireproof hybrid adhesive, stir evenly, add 130g of curing agent, and continue stirring until uniformly coated EPS particles are obtained; microwave heating and drying Dry for about 0.5min, and dry with hot air for about 1min to obtain gelled EPS particles;

[0036] Compression molding: Put the above-mentioned uniformly coated EPS particles into the mold and pressurize it, place the mold in a heating device with a temperature of about 120°C, keep it for 1-2min, cool down, and open the mold...

Embodiment 3

[0038] Preparation of fireproof hybrid adhesive: 1 part of aluminum dihydrogen phosphate, 0.5 part of phenolic resin, 0.2 part of melamine formaldehyde resin, 0.15 part of diisocyanate, 0.15 part of isopentane, DC-193 and non-silicone surfactant 0.05 parts of mixed substances of Wen-80;

[0039] Preparation of curing agent: 1 part of zirconia, 1 part of silicon nitride, 20 parts of alumina;

[0040] Coating of EPS foam particles: Take 100g of pre-haired and matured EPS particles, 1500g of fireproof hybrid adhesive, stir evenly, add 160g of curing agent, and continue stirring until uniformly coated EPS particles are obtained; microwave heating and drying Dry for about 0.5min, and dry with hot air for about 1min to obtain gelled EPS particles;

[0041] Compression molding: Put the above-mentioned uniformly coated EPS particles into the mold and pressurize it, place the mold in a heating device with a temperature of about 120°C, keep it for 1-2min, cool down, and open the mold t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com