Fiber neat paste test piece forming method for scanning microscope

A technology of scanning microscopy and forming method, which is applied in the field of microscopic testing, can solve the problem that it is difficult to guarantee the shape, size and surface smoothness of the test piece, it is difficult to ensure that the test piece can meet the experimental requirements, and the shape of the test piece can only be relatively simple, etc. problems, to achieve the effect of facilitating observation, saving manpower and material resources, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

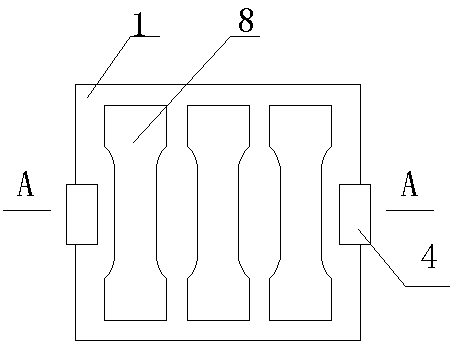

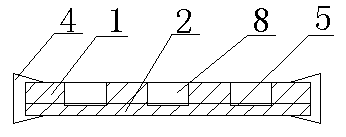

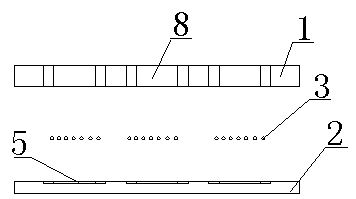

[0020] carved as figure 1 , 2 For the upper mold 1 and the bottom plate 2 shown, brush oil on the surface of the upper mold 1 and the bottom plate 2, weigh 500g of cement and 150ml of water and stir with the NJ-160A slurry mixer, set it to automatic mixing, and clean the slurry with cement after the mixing is completed Fill the groove 5 on the bottom plate 2, vibrate lightly 20 times, level it, repeat 2 times, place the basalt fiber 3 parallel to the surface of the filled groove 5 along the length direction of the test piece, place the mold 1 on Fix the bottom plate 2 and the upper mold 1 with the clamp 4 at the corresponding position on the base plate 2, and wait for half an hour to wait for the initial setting of the cement slurry; stir the cement slurry with the same mixing ratio again, and fill the through groove 8 of the upper mold 1 , gently vibrated 20 times, leveled, and repeated 2 times until the surface of the test piece was flat, removed the mold after 24 hours, an...

Embodiment 2

[0022] carved as figure 1 , 2 The upper mold 1 and the bottom plate 2 are brushed with oil on the surface, weighed 500g of cement and 148ml of water and stirred with an NJ-160A pure slurry mixer, set to automatic stirring, and filled the groove 5 on the bottom plate 2 with the clean slurry after the stirring is completed , gently vibrated 20 times, leveled, repeated 2 times, put the plastic steel fiber 3 parallel to the surface of the filled groove 5 along the length direction of the test piece, put the upper mold 1 on the corresponding position on the bottom plate 2, and use the clamp 4. Fix the bottom plate 2 and the upper mold 1, let it stand for half an hour, and wait for the initial setting of the cement slurry; stir the cement slurry with the same mix ratio again, fill the through groove 8 of the upper mold 1, and vibrate gently 20 times, Leveling, repeating 2 times until the surface of the test piece 7 is flat, remove the mold after 24 hours, take it out after 28 days ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com