Reactor pressure vessel simulation test platform for nuclear power plant

A test platform and pressure vessel technology, applied in instruments, educational appliances, teaching models, etc., can solve problems such as difficulty, radioactive contamination of equipment, unsatisfactory processing conditions in processing workshops, etc., to ensure safety, and ensure maintenance and maintenance cycles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

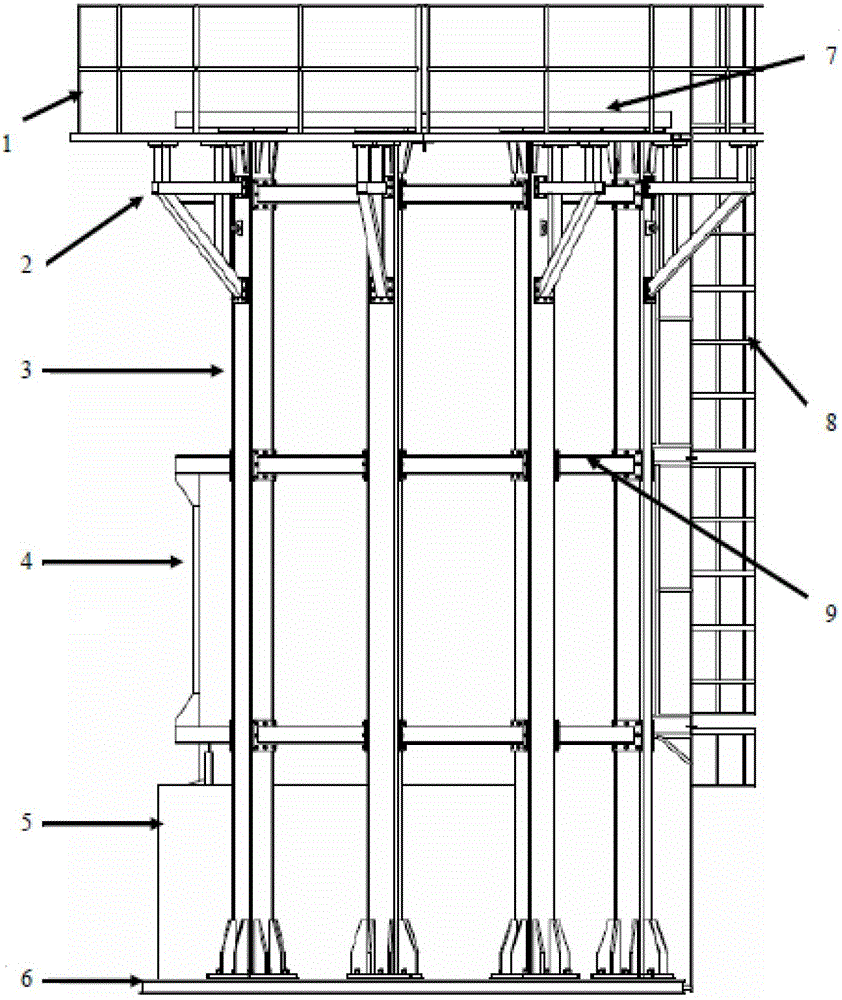

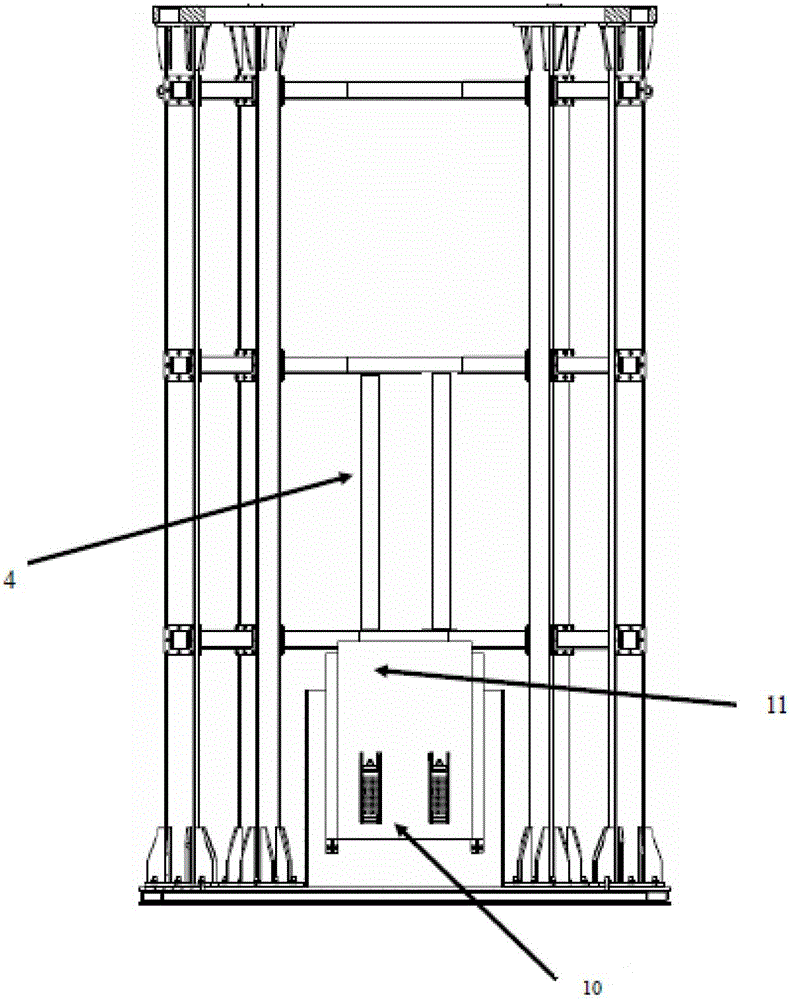

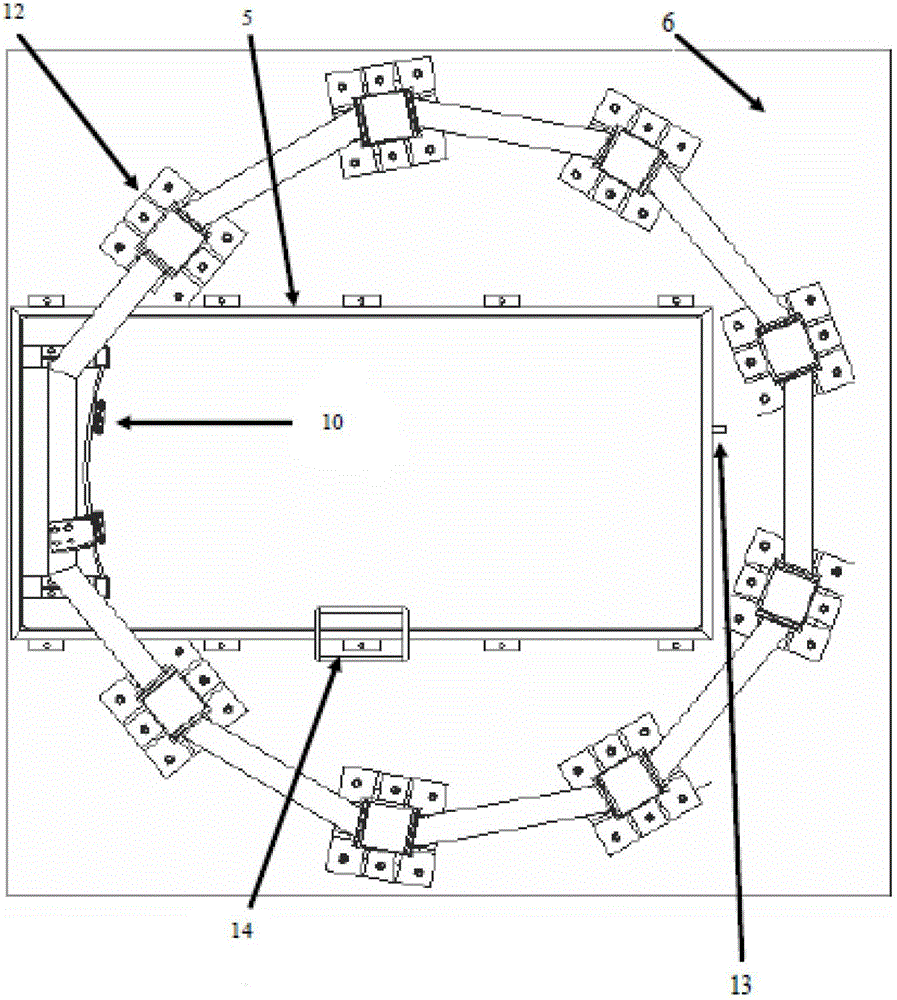

[0031] The present invention includes a personnel operation platform 1, an oblique support 2, a test platform support column 3, a simulated pressure vessel wall stand 4, a test platform simulated pool 5, a test platform base 6, a pressure vessel simulated flange 7, a test platform ladder 8, and a test platform. Platform crosspiece 9, sample box simulation metal storage rack and sample box simulation piece 10, pressure vessel simulation cylinder wall 11, test platform support column bottom flange 12, test platform simulation pool inlet and outlet pipes 13, and test platform simulation pool ladder 14.

[0032] The personnel operation platform 1 is mainly used for operators to stand beside the simulated flange of the pressure vessel and engage in operations related to reactor pressure vessel maintenance, training, tool debugging and verification. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com