Method for in-situ synthesis of compound of rutile TiO2 mesocrystal and graphene

An in-situ synthesis and graphene technology, applied in the direction of sustainable manufacturing/processing, electrical components, electrochemical generators, etc., can solve the problems of difficult synthesis, hidden dangers of safety performance, poor rate performance, etc., and achieve good reproducibility, The effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

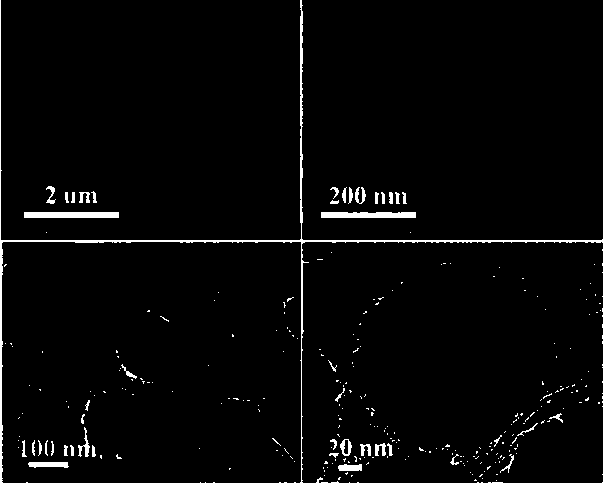

[0022] A kind of rutile TiO 2 The preparation method of mesogen and graphene compound, comprises the following steps:

[0023] 1) Disperse 0.68 mL of dodecylbenzenesulfonic acid in 70 mL of 2 mol / L nitric acid solution;

[0024] 2) After a uniform emulsion is formed, add 2 mL graphene oxide solution (5 mg / mL) dropwise, stir evenly, and finally add 0.68 mL tetrabutyl titanate dropwise, and continue stirring evenly;

[0025] 3) The resulting mixture was reacted in a water bath at 70 °C for 48 h, taken out, cooled to room temperature naturally, centrifuged to separate the product, washed 5 times with alcohol water, and dried to obtain rutile TiO 2 Mesogenic and graphene oxide composites.

[0026] 4) Weigh 100 mg rutile TiO 2 The composite of mesogen and graphene oxide was dispersed in 35 mL of water, put into a reaction vessel, and reacted in an oven at 140 °C for 6 h, taken out, cooled naturally to room temperature, centrifuged to separate the product, washed with alcohol wat...

Embodiment 2

[0031] A kind of rutile TiO 2 The preparation method of mesogen and graphene compound, comprises the following steps:

[0032] 1) Disperse 1.035 mL of dodecylbenzenesulfonic acid in 70 mL of 2 mol / L nitric acid solution;

[0033] 2) After a uniform emulsion is formed, add 3 mL graphene oxide solution (5 mg / mL) dropwise, stir evenly, and finally add 0.68 mL tetrabutyl titanate dropwise, and continue stirring evenly;

[0034] 3) The resulting mixture was reacted in a water bath at 70 °C for 48 h, taken out, cooled to room temperature naturally, centrifuged to separate the product, washed 5 times with alcohol water, and dried to obtain rutile TiO 2 Mesogenic and graphene oxide composites.

[0035] 4) Weigh 100 mg rutile TiO 2 The composite of mesogen and graphene oxide was dispersed in 35 mL of water, put into a reaction kettle, and reacted in an oven at 140 °C for 6 h, then taken out, cooled naturally to room temperature, centrifuged to separate the product, washed with alcoh...

Embodiment 3

[0039] A kind of rutile TiO 2 The preparation method of mesogen and graphene compound, comprises the following steps:

[0040] 1) Disperse 0.68 mL of dodecylbenzenesulfonic acid in 70 mL of 4 mol / L nitric acid solution;

[0041] 2) After a uniform emulsion is formed, add 2 mL of graphene oxide solution (5 mg / mL) dropwise, stir evenly, and finally add 0.68 mL tetrabutyl titanate dropwise, and continue stirring evenly;

[0042]3) The resulting mixture was reacted in a water bath at 70 °C for 72 h, taken out, cooled to room temperature naturally, centrifuged to separate the product, washed 5 times with alcohol water, and dried to obtain rutile TiO 2 Mesogenic and graphene oxide composites.

[0043] 4) Weigh 100 mg rutile TiO 2 The composite of mesogen and graphene oxide was dispersed in 35 mL of water, put into a reaction kettle, and reacted in an oven at 140 °C for 6 h, then taken out, cooled naturally to room temperature, centrifuged to separate the product, washed with alco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com