Supporting system used for rotor of high-speed and high-power interior permanent magnet synchronous motor and provided with reinforcing ribs

A permanent magnet synchronous motor and rotor support technology, which is applied to the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., can solve the problems that the electromagnetic performance and mechanical strength of the permanent magnet synchronous motor cannot be balanced, and achieve the improvement of electromagnetic performance , Improve the electromagnetic performance, the effect of margin increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

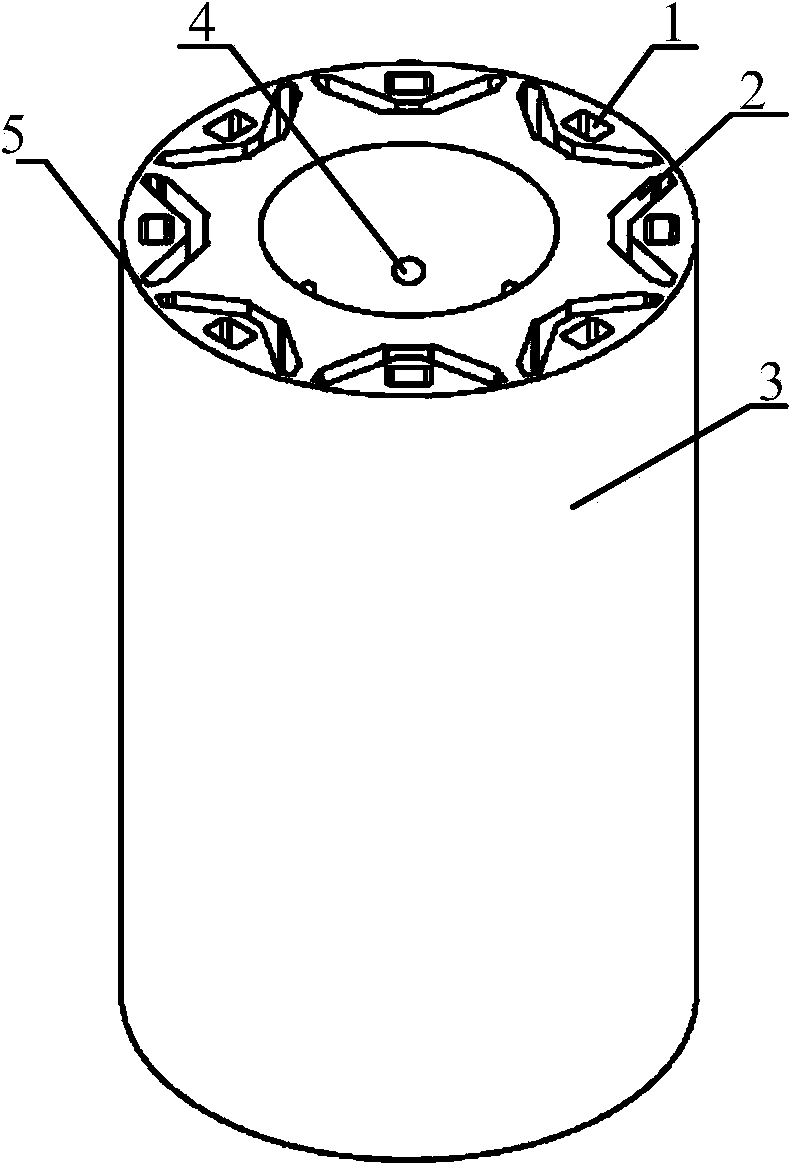

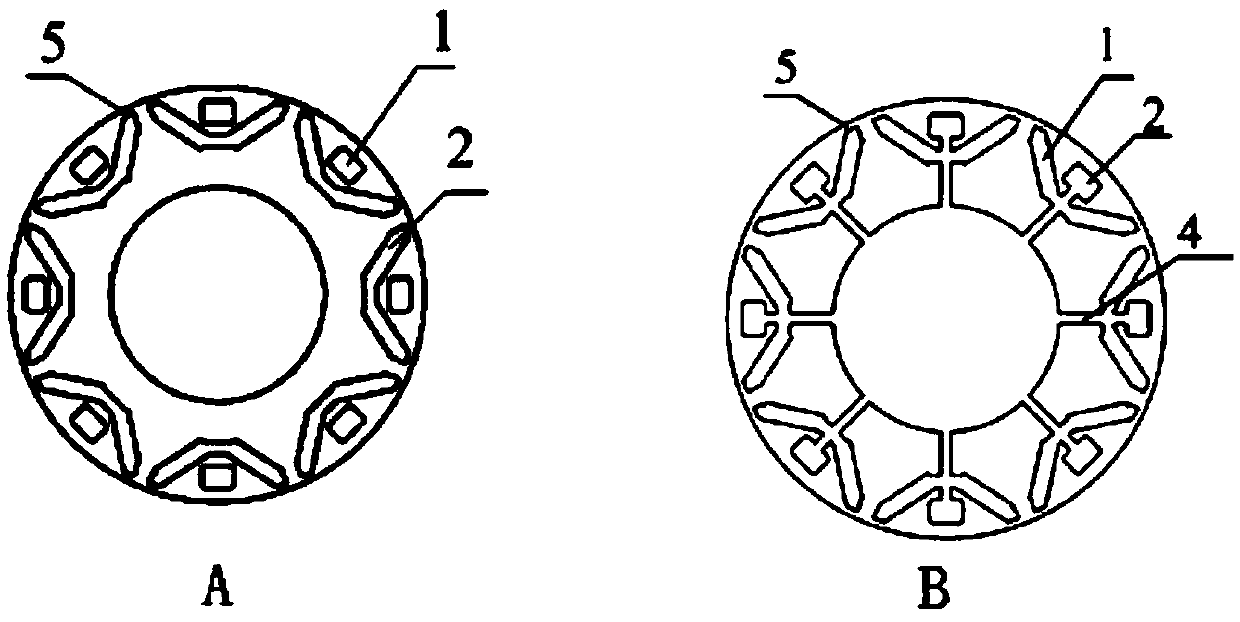

[0045] see figure 1 and Figure 6 , a high-speed and high-power built-in permanent magnet synchronous motor rotor support system with ribs. Like the existing motor rotor, the motor rotor includes a rotor core 3 , permanent magnet bars and a rotating shaft 8 , and the rotor core 3 is provided with a central axis hole and several permanent magnet slots 2 in the axial direction. In the embodiment, the cross-section of the permanent magnet slots 2 is "V" shaped, evenly distributed around the central axis hole. The part between the permanent magnet slot 2 and the outer wall of the rotor core 3 is called a magnetic isolation bridge.

[0046] Also includes screw rod 7, axle sleeve 11 and beam 6.

[0047] The rotor core 3 has several beam slots 1 for inserting beams 6 and several screw holes 4 for screw rods 7 to pass through.

[0048] Several beam slots 1 are distributed outside the permanent magnet slots 2 . The screw hole 4 runs through the central axis hole, the permanent mag...

Embodiment 2

[0055] see figure 1 and Figure 9, a high-speed and high-power built-in permanent magnet synchronous motor rotor support system with reinforcing ribs, including a rotor core 3, a permanent magnet bar and a rotating shaft 8, the rotor core 3 has a central axis hole and several Permanent magnet slots 2, the permanent magnet slots are distributed around the central hole. In the embodiment, the cross-section of the permanent magnet slots 2 is "V" shaped, evenly distributed around the central axis hole. The part between the permanent magnet slot 2 and the outer wall of the rotor core 3 is called a magnetic isolation bridge.

[0056] It also includes screw rod 7, beam 6 and dovetail tenon 12.

[0057] The rotor core 3 has several beam slots 1 for inserting beams 6 and several screw holes 4 for screw rods 7 to pass through.

[0058] Several beam slots 1 are distributed outside the permanent magnet slots 2 . The screw hole 4 runs through the central axis hole, the permanent magne...

Embodiment 3

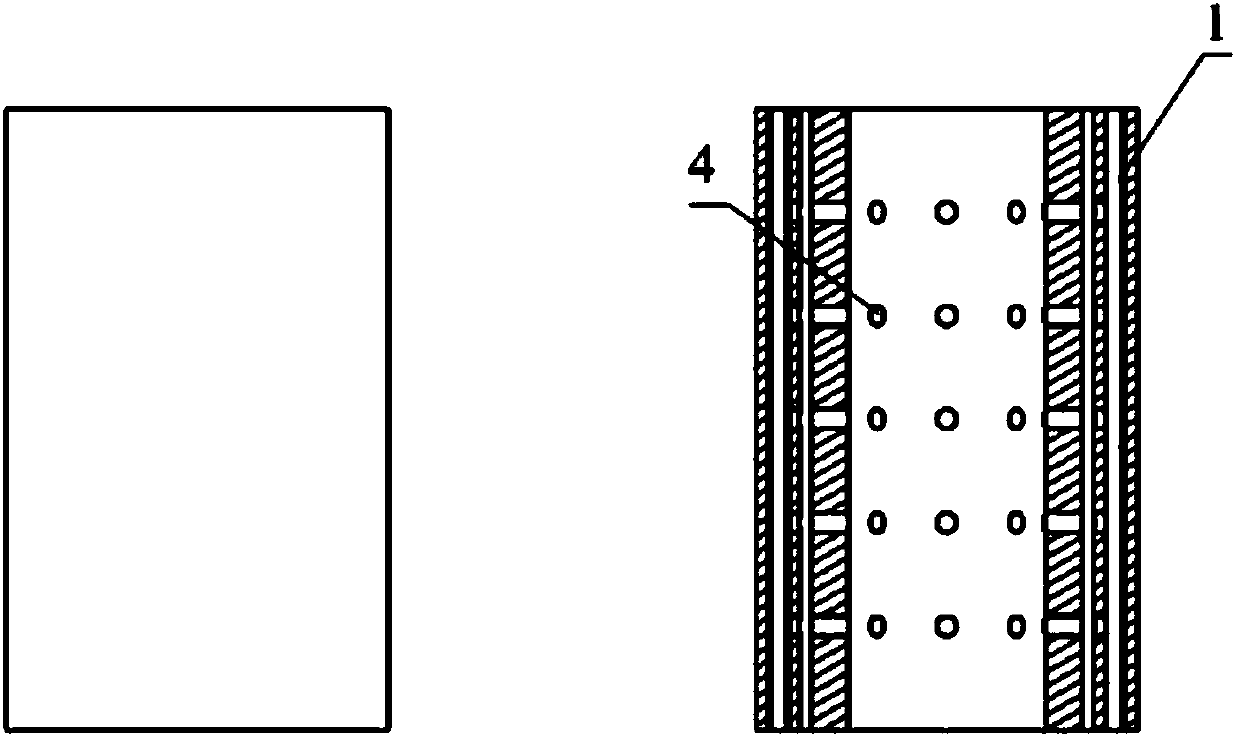

[0067] The main structure of this embodiment is the same as that of Embodiment 1 or 2, and the rotor core 3 is formed by laminating several silicon steel sheets I and several silicon steel sheets II.

[0068] The center of the silicon steel sheet I has a central shaft hole through which the rotating shaft 8 passes. Around the shaft hole of the silicon steel sheet I, there are distributed some permanent magnet slots 2 for the permanent magnet bars to pass through. The outer side of the permanent magnet slot 2 has a beam slot 1 through which the beam 6 passes.

[0069] The center of the silicon steel sheet II has a central shaft hole through which the rotating shaft 8 passes. Around the shaft hole of the silicon steel sheet II, there are several permanent magnet slots 2 for the permanent magnet bars to pass through. The outer side of the permanent magnet slot 2 has a beam slot 1 through which the beam 6 passes. The silicon steel sheet II also has screw grooves. One end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com