Piezoelectric floor device of blocking cantilever beam structure

A cantilever beam and piezoelectric technology, applied in the direction of piezoelectric effect/electrostriction or magnetostriction motors, electrical components, generators/motors, etc., can solve the problem of insufficient power generation capacity and small deformation of piezoelectric materials and other issues to achieve the effect of light weight and high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

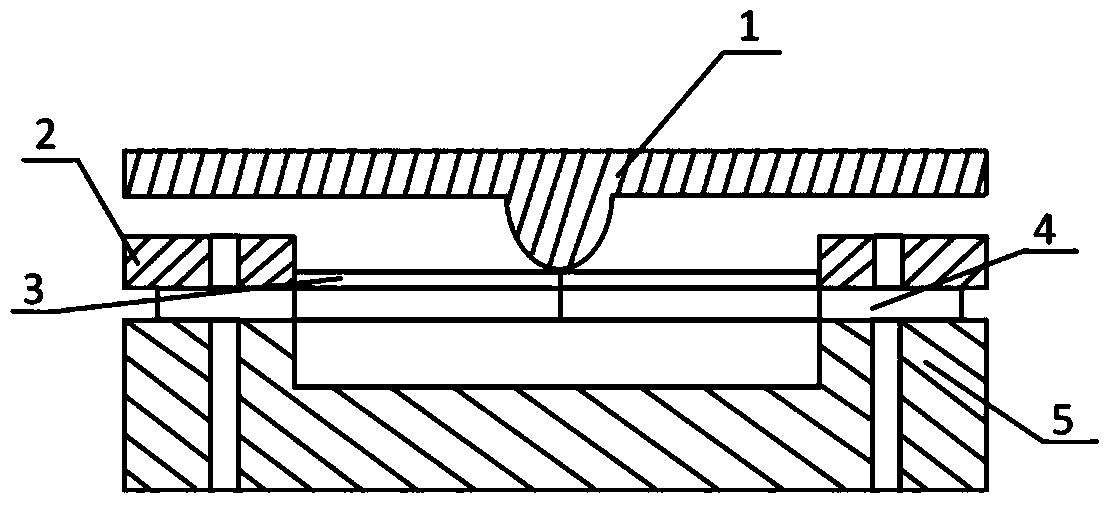

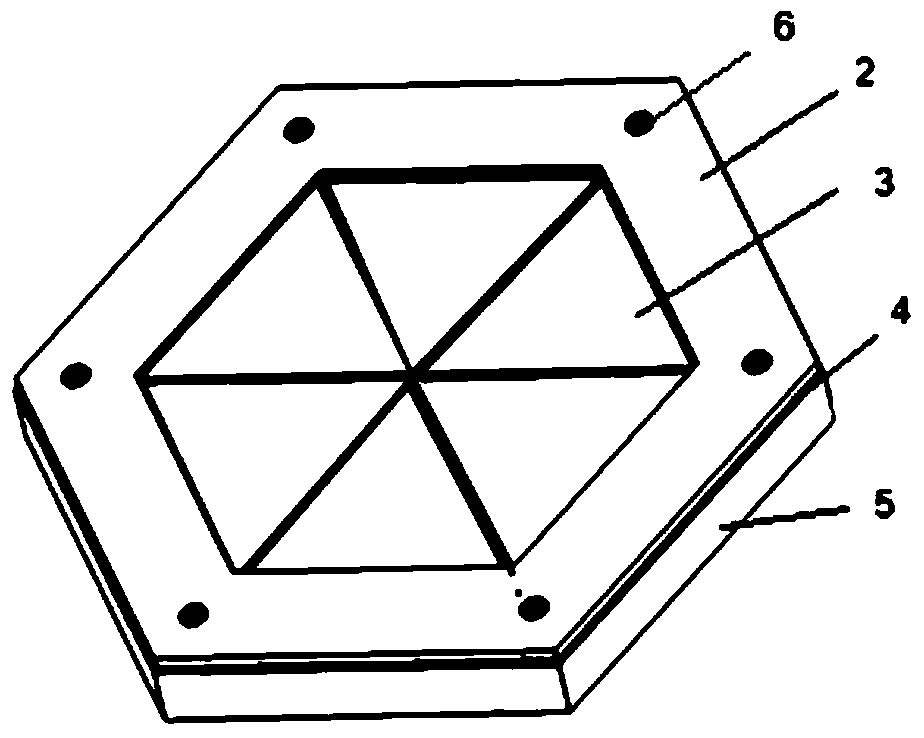

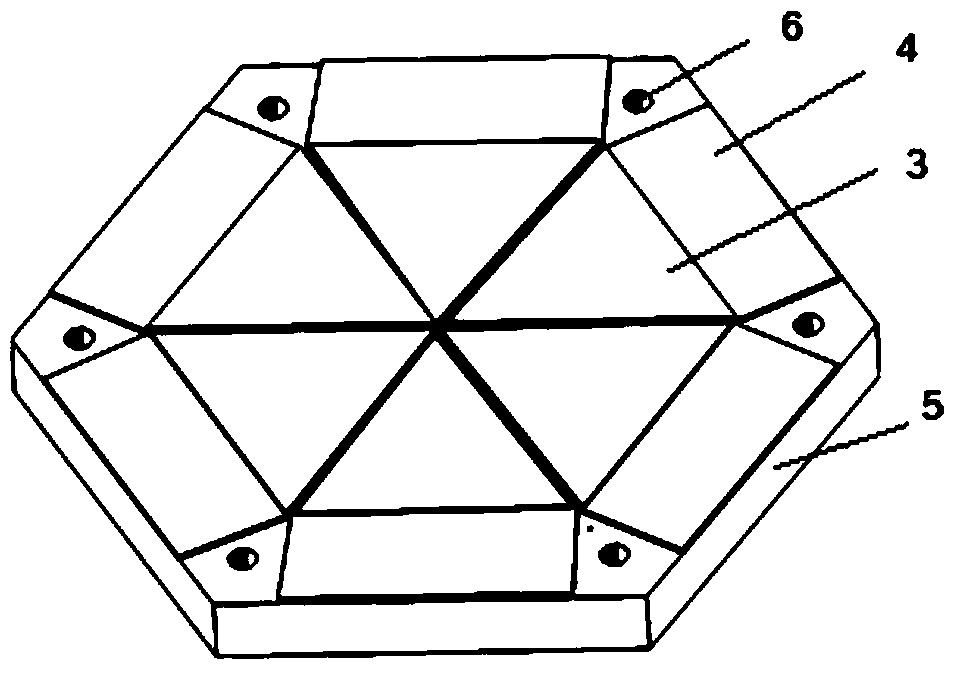

[0014] Embodiment 1, using a piezoelectric floor 7 composed of hexagonal piezoelectric units:

[0015] The thicknesses of the piezoelectric sheet 3 and the substrate 4 of a triangular structure with a vertex angle of 60 degrees and a hypotenuse length of 25 mm are 0.2 mm and 0.4 mm, respectively. The material of the piezoelectric sheet 3 should be selected according to the specific application. For example, you can choose piezoelectric single crystals, such as lead magnesium niobate-lead titanate PMN-PT, lead-free piezoelectric materials, sodium bismuth titanate-barium titanate NBBT, etc., which have good piezoelectric performance or are relatively cheap. Sheet material. You can choose circular, square, triangular, hexagonal and other shapes to cut according to size, and paste the selected six regular triangular piezoelectric sheets on the six substrates 4 respectively, and the six substrates 4 are installed on the bottom plate 5 in the form of a circle. Install the pressure...

Embodiment 2

[0016] Embodiment 2, using 4 triangular cantilever beams to form a square piezoelectric unit:

[0017] The thicknesses of the piezoelectric sheet 3 and the phosphor bronze substrate 4 having a triangular structure with a vertex angle of 90 degrees and a hypotenuse length of 25 mm are 0.17 mm and 0.34 mm, respectively. Four 90-degree triangular cantilever beams form a square as a unit, and the 90-degree triangular piezoelectric structural unit includes a cantilever beam piezoelectric sheet, a base plate, a pressure plate, and a cover plate. The installation method is the same as in Example 1. Also on a 25cm×30cm floor, 20 square piezoelectric units can be laid, with a coverage rate of 84%.

Embodiment 3

[0018] Embodiment 3, using three 120-degree triangular cantilever beams to form a square piezoelectric unit:

[0019] The thicknesses of the piezoelectric sheet 3 with a triangular structure and the phosphor bronze substrate 4 with a vertex angle of 120 degrees and a hypotenuse length of 25 mm are 0.13 mm and 0.26 mm, respectively. Three 120-degree triangular piezoelectric cantilever beams form a square piezoelectric unit, and the installation method is the same as Example 1. Similarly, 20 square piezoelectric units can be laid on a 25cm×30cm floor, and the coverage rate reaches 84%.

[0020] The output power curves of piezoelectric floors with different structures under the same thickness and the same displacement are compared by ANSYS software simulation. Figure 4 and Figure 5 Respectively represent the output power curves when a 100kg pedestrian steps on a 20cm×20cm floor, the top angle is 60 degrees, 90 degrees, 120 degrees, and the thickness of the piezoelectric sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com