Calcium alginate supported metal phthalocyanine microsphere catalytic material and preparation method thereof

A metal phthalocyanine, calcium alginate technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of non-metallic phthalocyanine catalytic degradation of organic pollutants Carry out research on performance and other issues to achieve the effect of easy recycling and reusability, and solve the problem of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

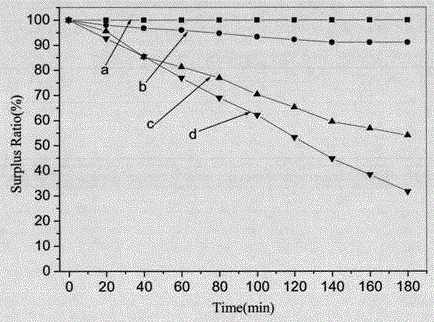

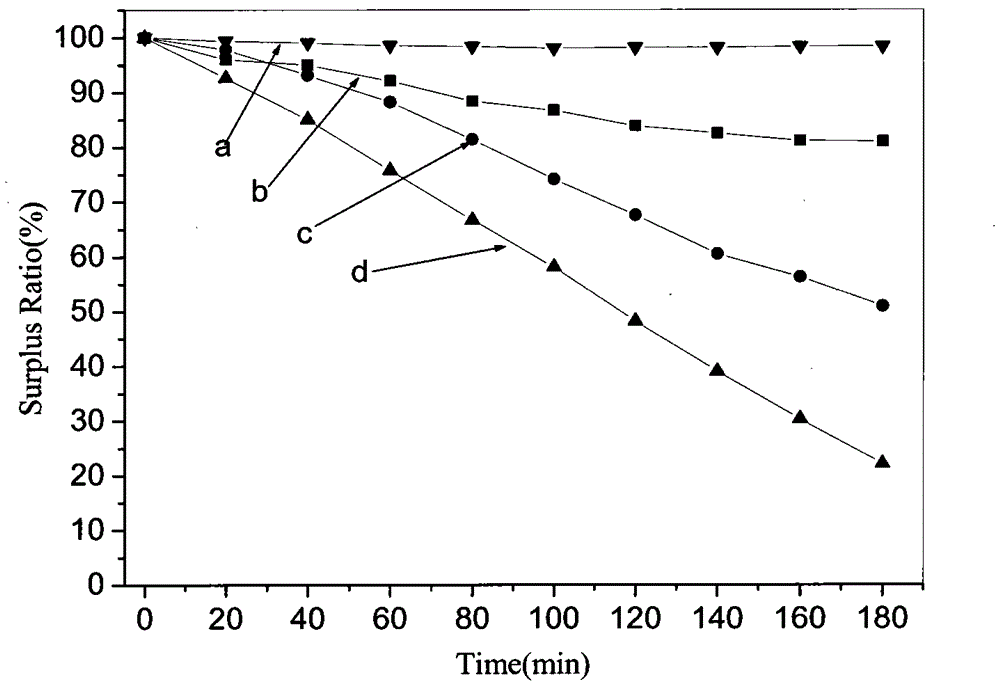

[0039] First, 0.1 g of tetracarboxyiron phthalocyanine (FePc) was dissolved in 10 mL of distilled water, ultrasonically oscillated for 30 minutes, then stirred for 18 hours to fully dissolve. Weigh 5g of sodium alginate and dissolve it in 100mL of distilled water at about 60°C, stir for 2 hours to finally obtain a light yellow colloidal substance. After both were fully dissolved, the phthalocyanine solution was slowly poured into the alginate gel and mixed with constant stirring for 2 hours. Put the dissolved sodium phthalocyanine alginate colloid in a vacuum drying oven for degassing. After the degassing is completed, pour the colloid into a 10mL disposable needle tube and add it dropwise to 50mL of 5% (mass) calcium chloride solution to form a ball. , and stood still for 12 hours, soaked in distilled water to remove the phthalocyanine on the surface of the microspheres. The loading of FePc in the loaded calcium alginate microspheres (FePc-SA-Ca) is 0.09% (mass percentage), ...

Embodiment 2

[0042] Firstly, 0.1 g of the prepared tetracarboxyl zinc phthalocyanine (ZnPc) was weighed and dissolved in 10 mL of distilled water, ultrasonically oscillated for 30 min, then placed on a stirrer and stirred for 18 hours. Weigh 1.0g of sodium alginate and slowly add it to 40mL of distilled water at about 20°C to dissolve, and keep stirring. After both were fully dissolved, the phthalocyanine solution was slowly poured into the alginate gel and mixed with constant stirring for 10 hours. The mixed gel was placed in a 10 mL syringe, freely dropped into 500 mL of 0.5% (mass) calcium chloride solution, formed into a ball, and stood still for 3 hours, soaked in distilled water to remove the phthalocyanine on the surface of the microsphere. The loading amount of ZnPc in the calcium alginate microspheres (ZnPc-SA-Ca) is 0.20% (mass percentage), the average diameter of the microspheres is about 3.6mm, and the average diameter of the microspheres after drying is about 1.3mm.

[0043] ...

Embodiment 3

[0045] Firstly, 0.5 g of the prepared tetracarboxyl zinc phthalocyanine (ZnPc) was weighed and dissolved in 10 mL of distilled water, ultrasonically oscillated for 30 min, then placed on a stirrer and stirred for 18 hours. Weigh 2g of sodium alginate and slowly add it to 40mL of distilled water at about 50°C to dissolve, and keep stirring. After both were fully dissolved, the phthalocyanine solution was slowly poured into the alginate gel and mixed with constant stirring for 10 hours. The mixed gel was placed in a 10 mL syringe, freely dropped into 300 mL of 5% (mass) calcium chloride solution, formed into a ball, and stood still for 3 hours, soaked in distilled water to remove the phthalocyanine on the surface of the microsphere. The loading amount of ZnPc in the calcium alginate microspheres (ZnPc-SA-Ca) is 0.95% (mass percentage), the average diameter of the microspheres is about 3.2mm, and the average diameter of the microspheres after drying is about 1.2mm.

[0046] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com