Car varnish spraying and baking room

A technology for baking paint booths and automobiles, applied in paint spray booths, spraying devices, coatings, etc., can solve problems such as uneven heating, dead angles, and low illumination, and achieve reasonable structural design, uniform painting effects, and high surface quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

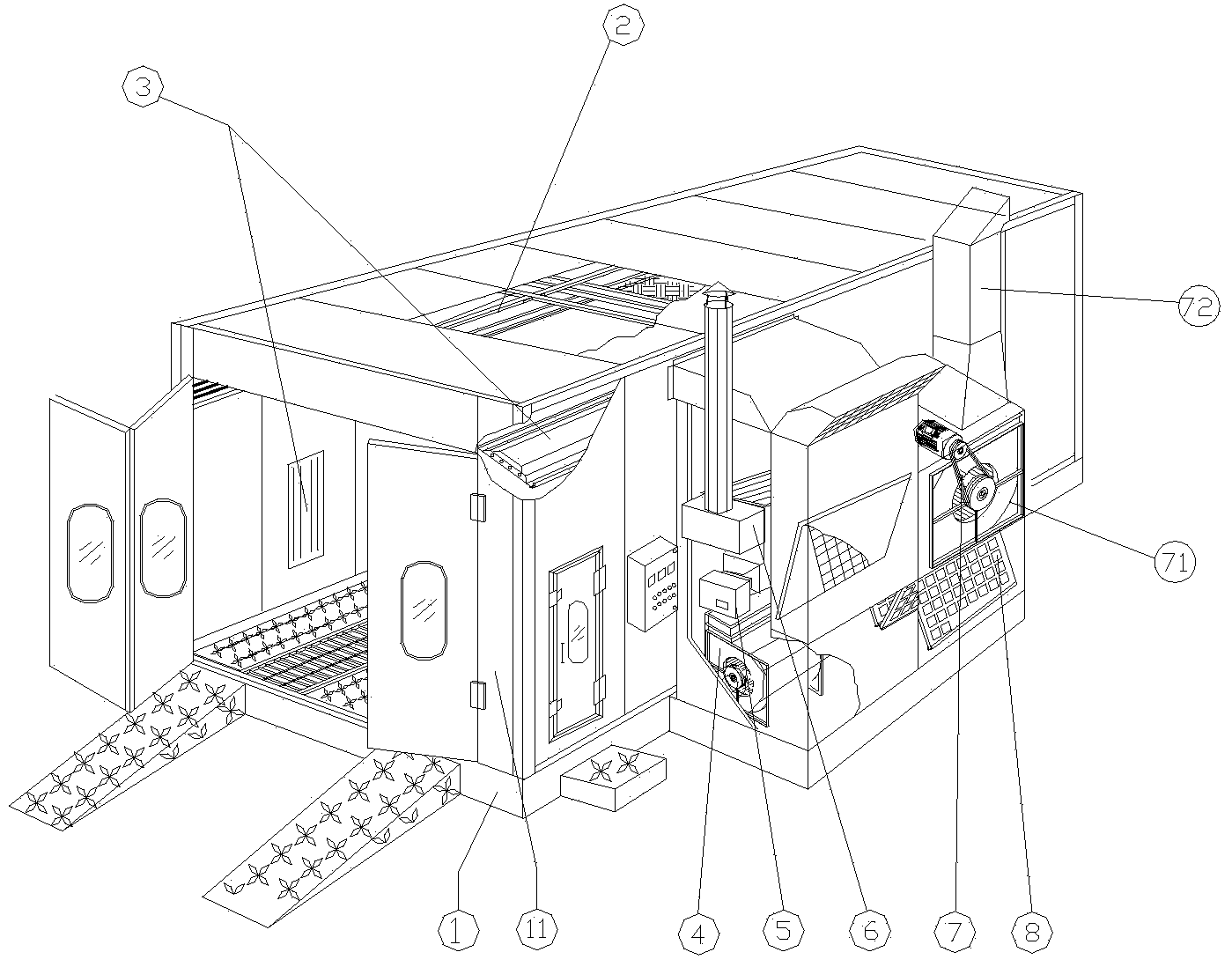

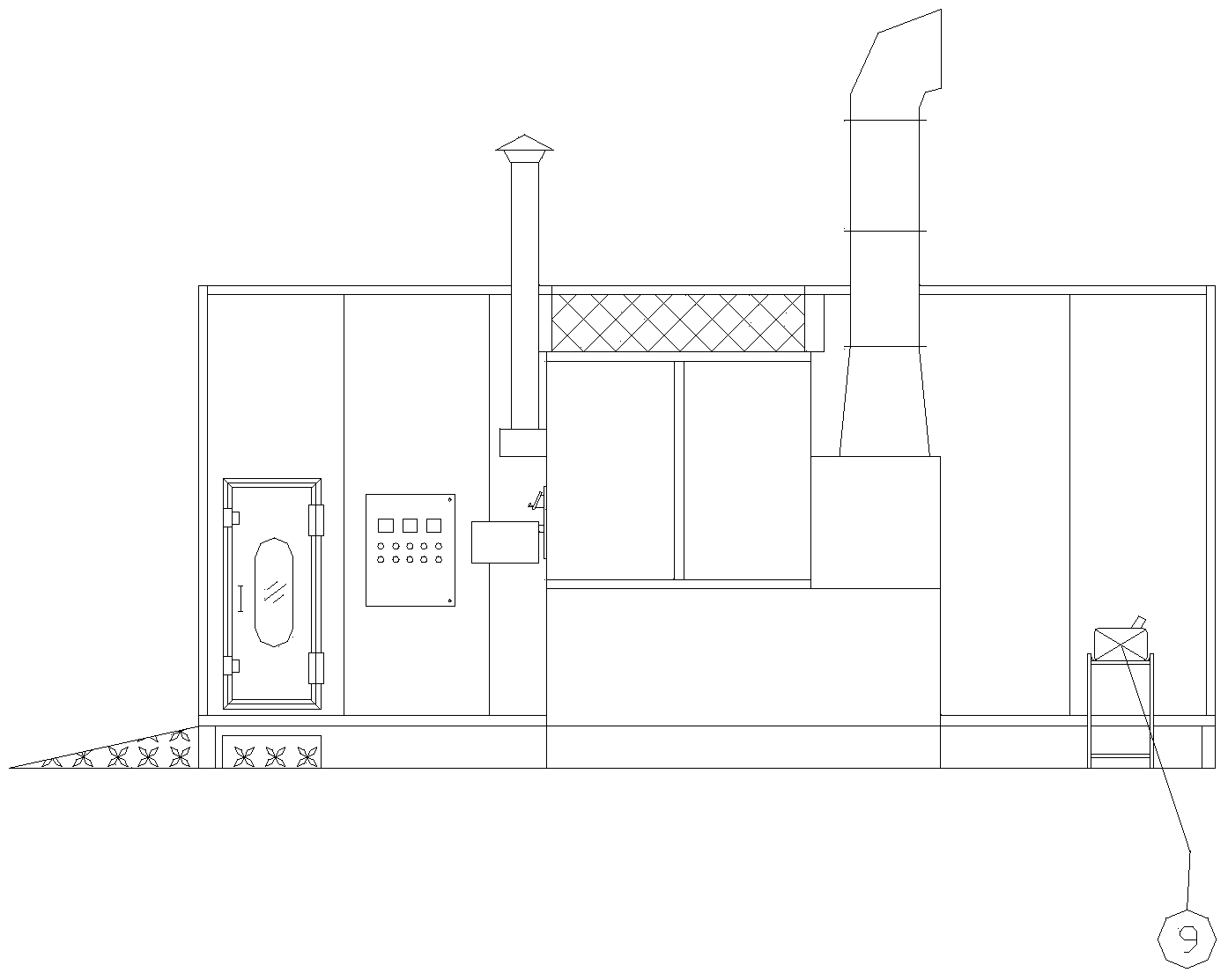

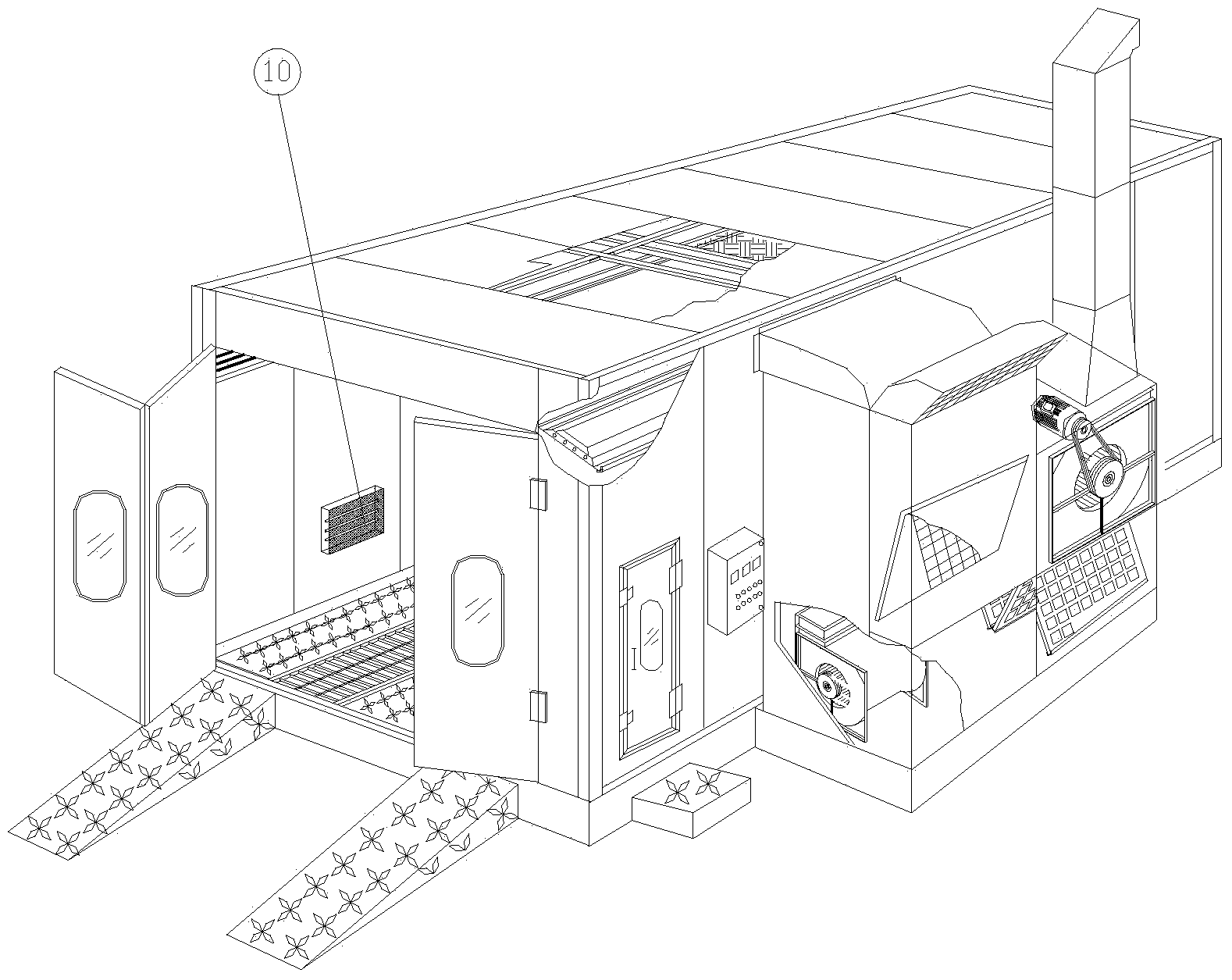

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0026] Such as Figure 1 to Figure 5 Shown: Automobile painting and baking room, including base 1, room body 11, air conditioning filter system 2, lighting system 3, air supply system 4, heating system, exhaust system 7, exhaust gas treatment system 8; the layout of the room body 11 On the base 1, the air-conditioning filter system 2 and the lighting system 3 are arranged on the inner top wall of the room body 11; And it communicates with the housing body 11 .

[0027] The room body system is mainly composed of: skeleton, wall board, roof board, static pressure chamber, workpiece entry door, escape safety door and base assembly. The strength, stability, heat preservation, airtightness, impact resistance, and earthquake resistance of the chamber body meet the requirements of national or relevant industry standards.

[0028] Skeleton: It is composed of vertical and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com