Self-centering electrolysis grinding combined machining device for inner hole

A technology of electrolytic grinding and composite processing, which is applied in the field of composite processing equipment, can solve the problems of restricting the application of inner hole grinding and reducing the productivity of electrolytic grinding, and achieve the effect of novel structure, low surface roughness and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings and embodiments.

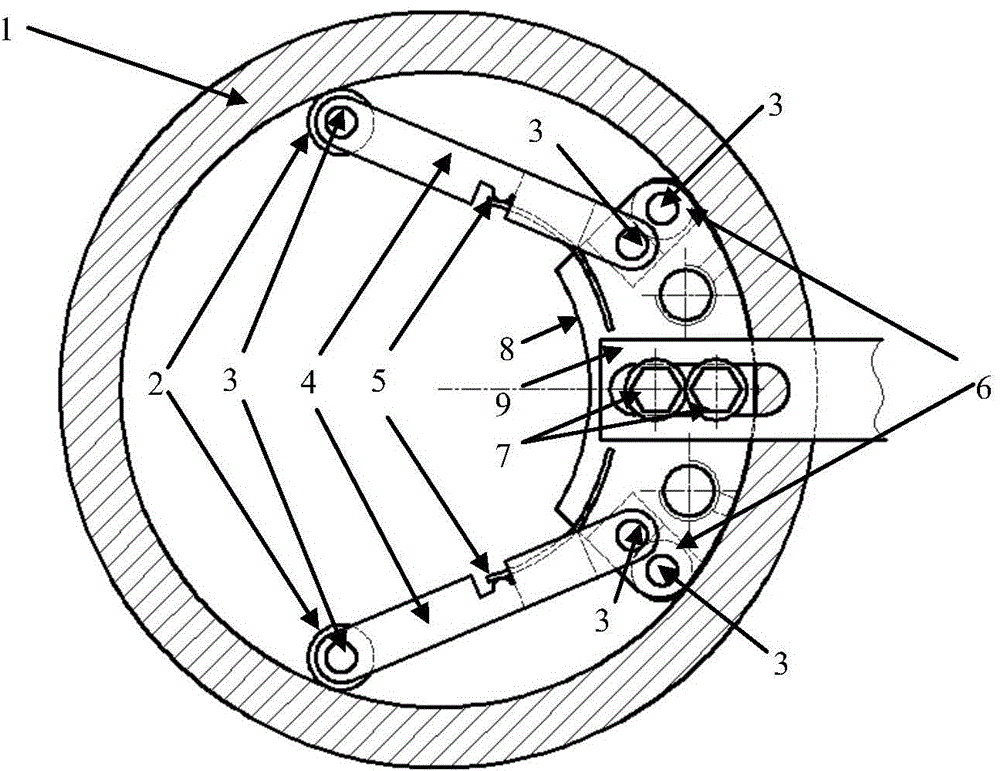

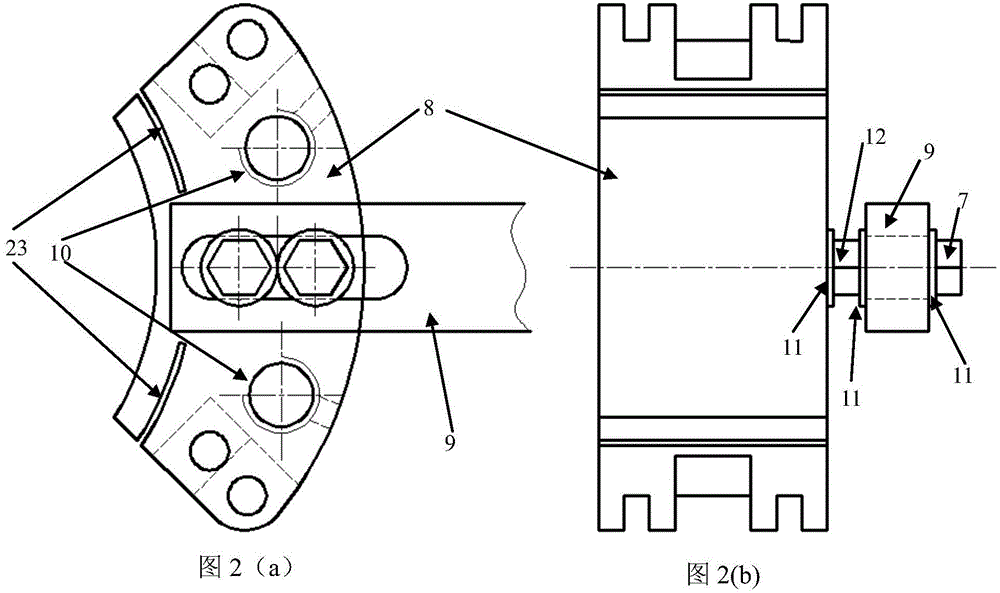

[0028] Such as Figure 1-Figure 4 As shown, the self-centering inner hole electrolytic grinding compound processing device includes a cathode 8 arranged in the inner hole of the workpiece, and four pins are fixed on the outer edge of the cathode to ensure the gap between the cathode 8 and the inner hole wall of the workpiece. The cathode roller 6 of the electrolysis gap;

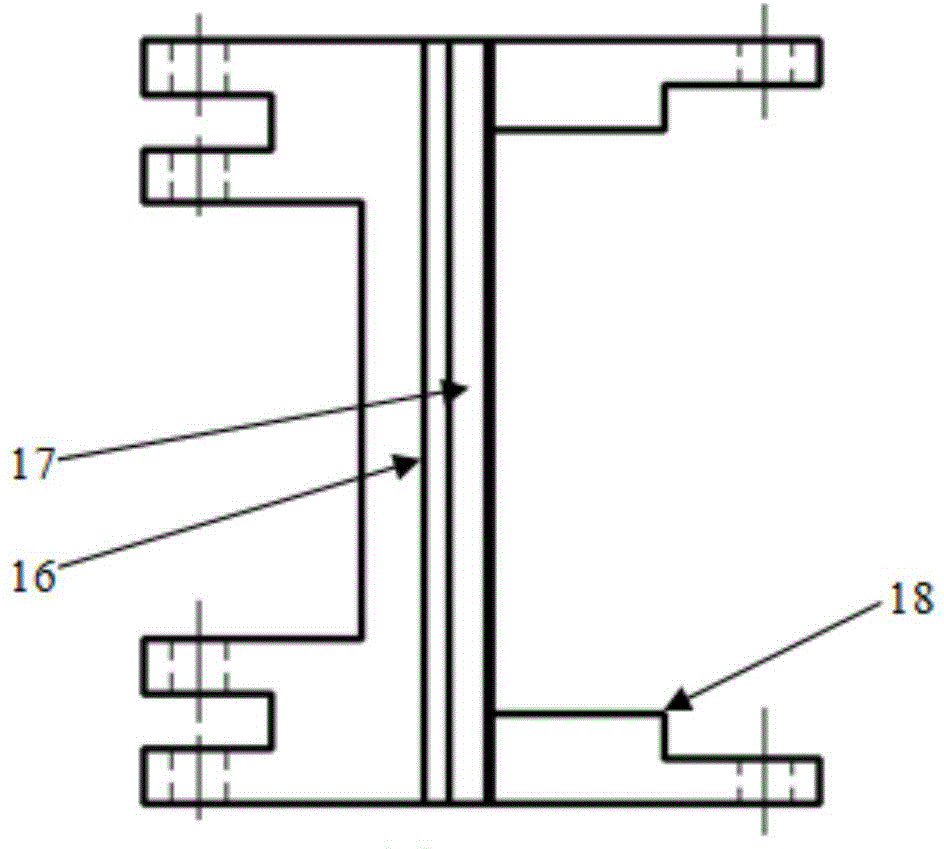

[0029] The cathode 8 is also provided with an arc-shaped cathode slot 23. The cathode slot 23 is provided with a spring sheet 5 with one end extended and embedded in it. The other end of the spring sheet 5 is set on the pawl 4; one end of the spring sheet 5 is pressed against the pawl 4 On the semicircular boss 17 on 4, the pawl 4 is in point contact with the spring plate 5, and the elastic force of the spring plate 5 is exerted to the greatest extent.

[0030] One end of the claw 4 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com