Catalyst component for olefin polymerization, catalyst containing catalyst component and application of catalyst

A technology for olefin polymerization and catalyst, applied in the direction of organic chemistry, etc., can solve the problem of unsatisfactory balance of activity/isotacticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

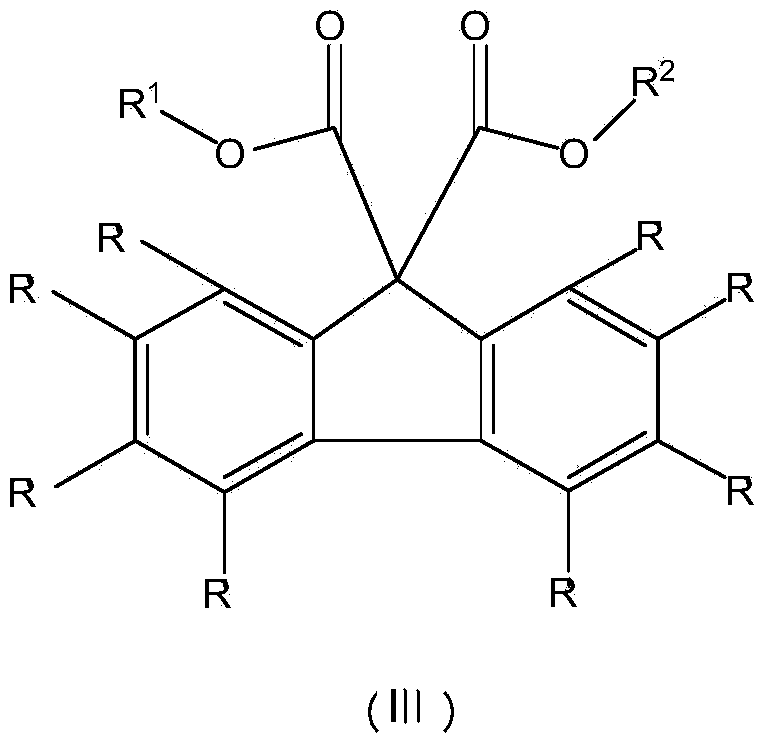

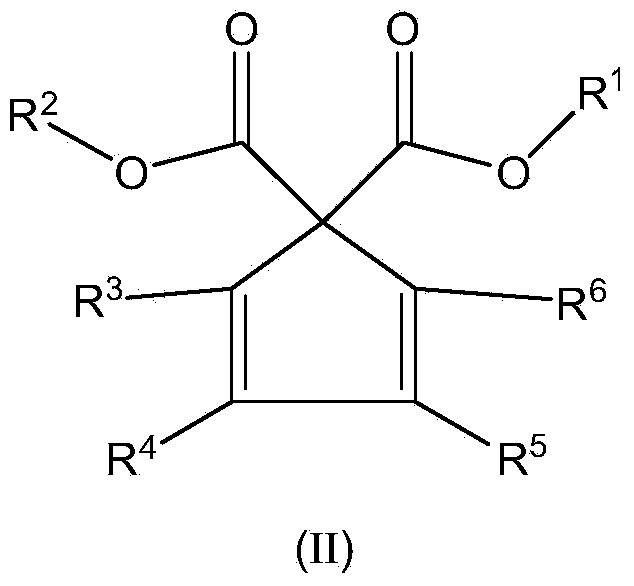

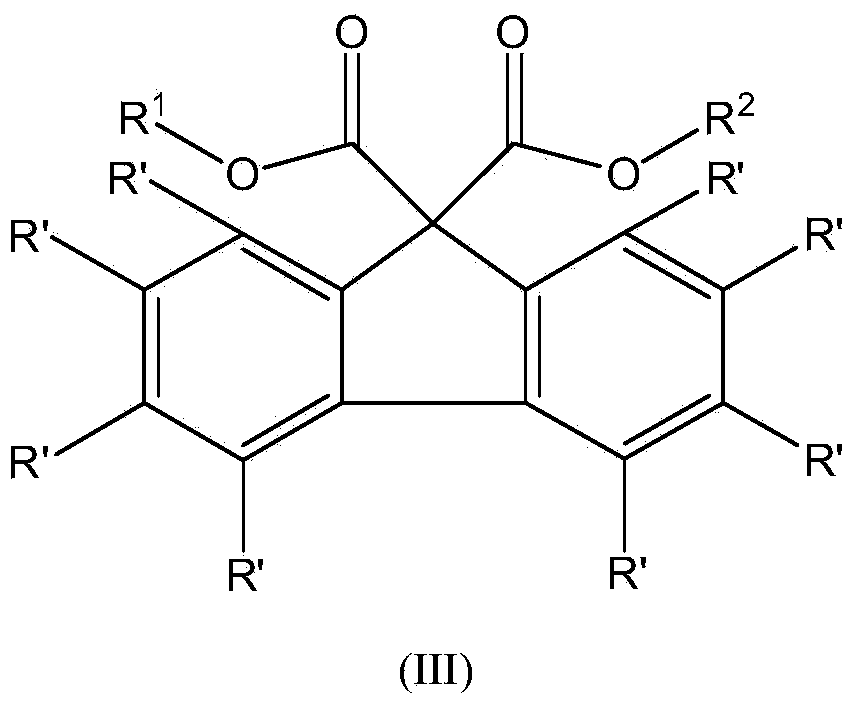

Method used

Image

Examples

Embodiment 1

[0072] Synthesis of embodiment 1 fluorene-9-methyl formate-9-ethyl formate

[0073] Step A: Add 18g of sodium hydride, 50g of fluorene, and 150mL of toluene to a 1000mL three-necked flask in sequence under nitrogen protection, turn on mechanical stirring, heat up to 125°C under reflux, and keep the reaction for 4h; cool down to 90°C, and slowly add 146.1 g diethyl carbonate, drop it within 1.5 hours, and continue to react for 3 hours after the drop; cool to 20°C, slowly add a mixture of 60g concentrated hydrochloric acid and 75g water, and control the temperature not to exceed 40°C; filter and separate the organic phase, washed with water until neutral, and the organic phase was rotary evaporated to obtain a reddish-brown liquid; the liquid obtained by rotary evaporation was refluxed overnight with 157.4g of acetic acid and 63g of 10% hydrochloric acid; the mixture was lowered to 20°C and separated; the organic phase was rotary evaporated Then add 30% NaOH solution to adju...

Embodiment 3

[0080] Embodiment 3 fluorene-9, the synthesis of dimethyl 9-dicarboxylate

[0081] The synthesis steps are the same as in Example 2, except that ethyl chloroformate is replaced by methyl chloroformate.

[0082] Dimethyl fluorene-9,9-dicarboxylate 1 H-NMR (CDCl 3 )δ (ppm): 3.759 (s, 6H, methyl hydrogen), 7.359-7.392 (t, 2H, aromatic ring hydrogen), 7.443-7.475 (t, 2H, aromatic ring hydrogen), 7.720-7.735 (d, 2H , aromatic ring hydrogen), 7.799-7.7814 (d, 2H, aromatic ring hydrogen).

Embodiment 4

[0083] Embodiment 4 fluorene-9, the synthesis of 9-dicarboxylic acid di-n-propyl ester

[0084] The synthesis steps are the same as in Example 2, except that ethyl chloroformate is replaced by n-propyl chloroformate.

[0085] Di-n-propyl fluorene-9,9-dicarboxylate 1 H-NMR (CDCl 3 )δ (ppm): 0.936-0.966 (t, 6H, methyl hydrogen), 1.664-1.735 (m, 4H, methylene hydrogen), 4.171-4.197 (t, 4H, oxygen o-methylene hydrogen), 7.389 -7.421 (t, 2H, aromatic ring hydrogen), 7.449-7.481 (t, 2H, aromatic ring hydrogen), 7.737-7.752 (d, 2H, aromatic ring hydrogen), 7.887-7.902 (d, 2H, aromatic ring hydrogen) .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com