Heat-conducting adhesive for LED (light-emitting diode) lamp packaging and preparation method thereof

A technology for LED lamps and thermally conductive adhesives, applied in adhesives, semiconductor devices, adhesive additives, etc., can solve problems such as increasing the thermal resistance between the substrate and the radiator, detaching the light source module radiator, increasing production costs, etc., to solve the curing time. and temperature problems, good market prospects, the effect of reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

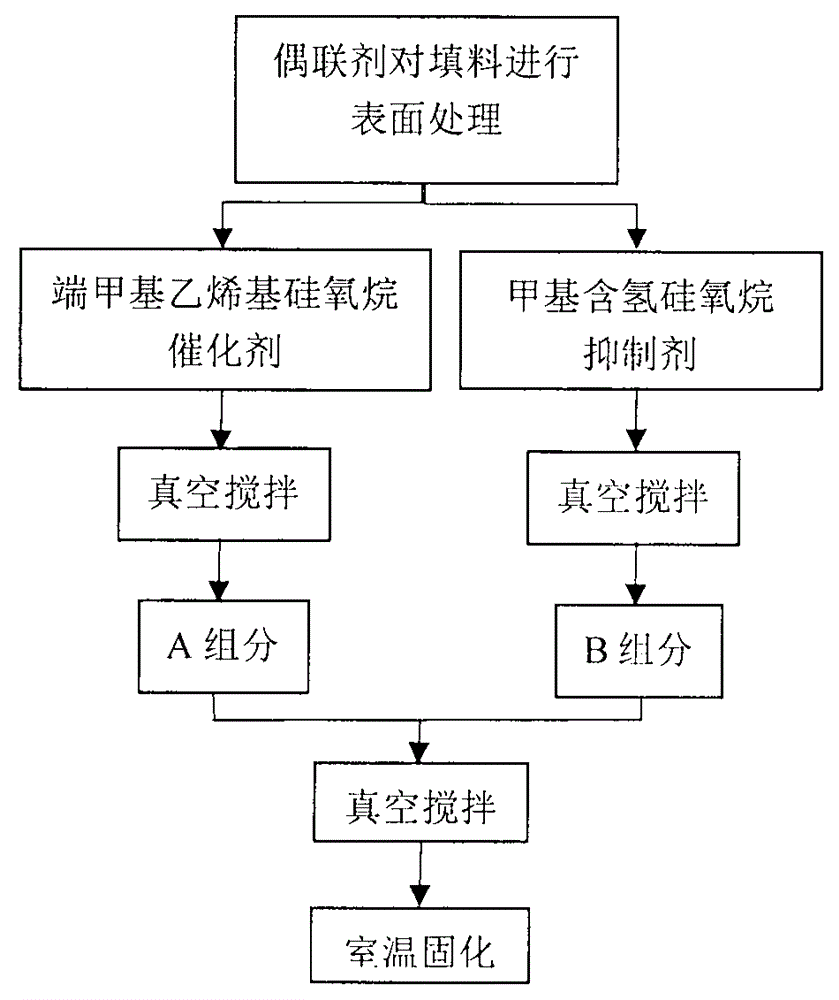

Method used

Image

Examples

Embodiment 1

[0019] a. Take 10 g of terminal methyl vinyl siloxane with a vinyl content of 160 mPas of 2.5%, 10 g of spherical alumina with a particle diameter of 5 μm, and 0.2 g of a platinum-vinyl siloxane complex catalyst, put them in a vessel, and place the The vessel is placed in a vacuum stirrer, at room temperature, the vacuum degree is 1×10 -1 Stir below MPa for 15min at a speed of 500r / min to obtain component A;

[0020] b. Take 7g of oxygen-containing siloxane with a hydrogen content of 0.18% at 140mPas, 6g of spherical alumina with a particle size of 13nm, and 0.01g of acetylenic alcohol inhibitors, put them in a vessel, and put the vessel in a vacuum stirrer , at room temperature, the vacuum degree is 1×10 -1 Stir for 15 minutes below MPa, and the rotating speed is 500 rpm to prepare component B;

[0021] c. Mix components A and B and put them in a vacuum mixer. At room temperature, the vacuum degree is 1×10 -1 Stir below MPa for 15 minutes at a speed of 600 rpm to prepare A...

Embodiment 2

[0023] a. Take 10g of terminal methyl vinyl siloxane with 160mPas vinyl content of 2.5%, 6g of spherical alumina with a particle size of 5μm, 4g of spherical aluminum nitride with a particle size of 50nm, platinum-vinyl siloxane complex Catalyst 0.3g, be placed in the container, this container is placed in the vacuum stirrer, at room temperature, vacuum degree is at 1 * 10 -1 Stir below MPa for 15min at a speed of 500r / min to obtain component A;

[0024] b. Take 7g of hydrogen-containing siloxane with a hydrogen content of 0.18% at 140mPas, 4g of spherical alumina with a particle size of 13nm, 2g of spherical aluminum nitride with a particle size of 2μm, and 0.01g of acetylenic alcohol inhibitors, and put them in a container Inside, put the vessel in a vacuum stirrer, at room temperature, the vacuum degree is 1×10 -1 Stir for 15 minutes below MPa, and the rotating speed is 500 rpm to prepare component B;

[0025] c. Mix components A and B and put them in a vacuum mixer. At r...

Embodiment 3

[0027] a. Take 10g of terminal methyl vinyl siloxane with 160mPas vinyl content of 2.5%, 6g of spherical alumina with a particle size of 5μm, 4g of spherical aluminum nitride with a particle size of 50nm, platinum-vinyl siloxane complex Catalyst 0.3g, be placed in the container, this container is placed in the vacuum stirrer, at room temperature, vacuum degree is at 1 * 10 -1 Stir below MPa for 15min at a speed of 500r / min to obtain component A;

[0028] b. Take 7g of hydrogen-containing siloxane with a hydrogen content of 0.18% at 140mPas, 3g of spherical alumina with a particle size of 13nm, 2g of spherical aluminum nitride with a particle size of 2μm, 1g of spherical copper powder with a particle size of 10μm, and acetylenic alcohol Inhibitors 0.01g, placed in a container, the container is placed in a vacuum stirrer, at room temperature, the vacuum degree is 1 × 10 -1 Stir for 15 minutes below MPa, and the rotating speed is 500 rpm to prepare component B;

[0029] c. Mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com