Split type high-speed rolling bearing body of turbocharger

A turbocharger, high-speed rolling technology, applied in the direction of bearing components, shafts and bearings, bearing cooling, etc., can solve the problems of unstable dynamic control, large running resistance, difficult maintenance, etc., and achieve good anti-contact fatigue characteristics and durability Grinding performance, reduced processing costs, and convenient layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

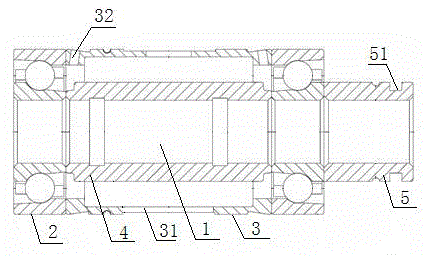

[0016] Such as figure 1 It is a structural schematic diagram of the present invention, a separate high-speed rolling turbocharger bearing body, including a turbine rotor shaft 1, an angular contact ball bearing 2, an outer spacer 3, an inner spacer 4 and a head cover 5, and an angular contact ball bearing 2 There are two, respectively sleeved on the two ends of the turbine rotor shaft 1, the outer spacer 3 and the inner spacer 4 are sandwiched between the two angular contact ball bearings 2, and the head cover 5 is installed on the top of the turbine rotor shaft 1. The outer spacer 3 is provided with an oil outlet hole 31 and an oil passage slope 32, which are embedded in the turbine shell hole, and the two ends are supported on the outer rings of the two angular contact ball bearings 2 respectively. The two ends of the inner spacer 4 arranged on the turbine rotor shaft 1 bear on the inner rings of the two angular contact ball bearings 2 respectively. The outer spacer 3 is sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com