Double ccd scanning imaging detection method for surface defects of continuous casting slab

A scanning imaging and detection method technology, applied in the field of iron and steel metallurgy, can solve the problems of recognition algorithm design and final recognition accuracy limit, it is difficult to ensure reliable defect recognition rate, phase unwrapping algorithm design is difficult, etc., to ensure clear imaging High degree, easy on-line detection and industrial implementation, and the effect of eliminating high-temperature radiation interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

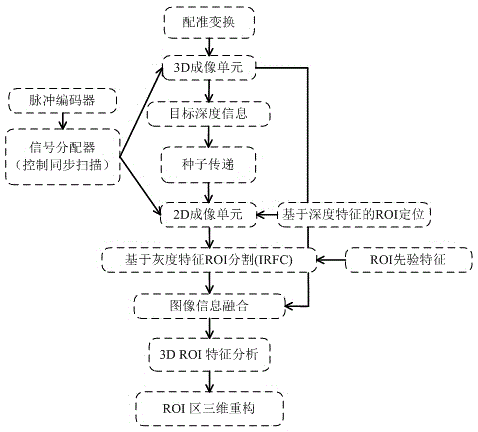

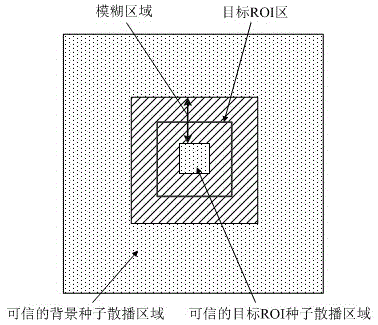

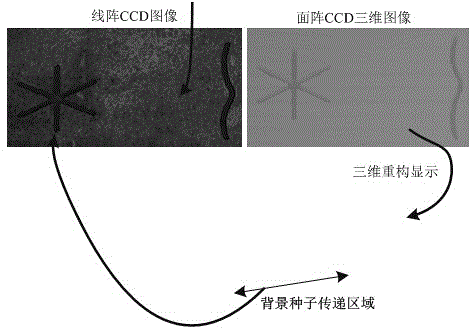

[0024] Before cutting the continuous casting slab or billet, it is the core content of this invention to accurately extract the image of the surface defect of the casting slab online, and to eliminate the surface vibration marks, iron oxide scale, residual mold slag layer and water film interference, and its purpose is to facilitate and reduce image recognition. The selection and extraction of the feature quantity of the area of interest on the surface during the process improves the defect recognition rate, reduces errors, simplifies the design complexity of the system defect classifier, and provides reliable technical support for the continuous casting slab surface quality assessment. The realization idea is to combine the conventional grayscale linear array CCD scanning imaging method with the laser three-dimensional ranging mapping scanning imaging technology based on the area array CCD, and accurately extract the two-dimensional shape and three-dimensional depth features ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com