Multi-purpose electrical window and manufacturing methods thereof

An electronic window and multi-functional technology, applied in the field of electronic windows, can solve problems such as poor shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

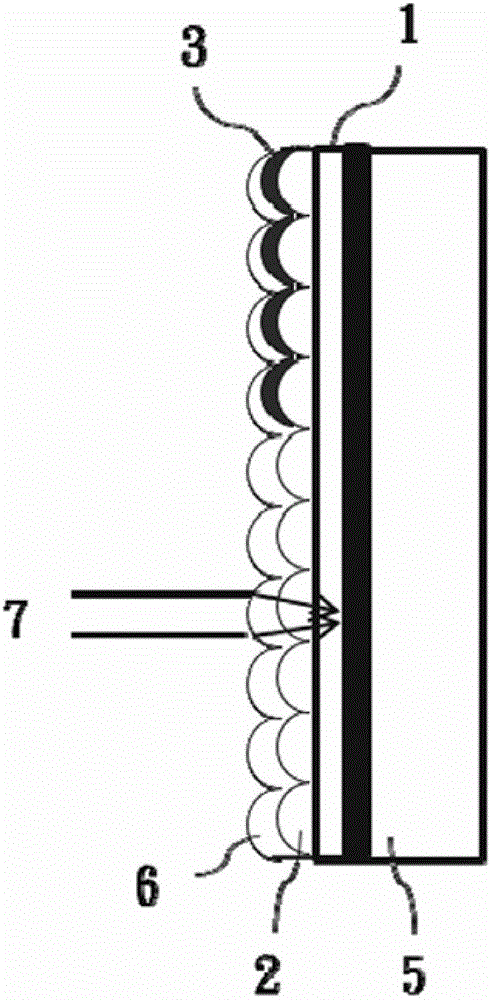

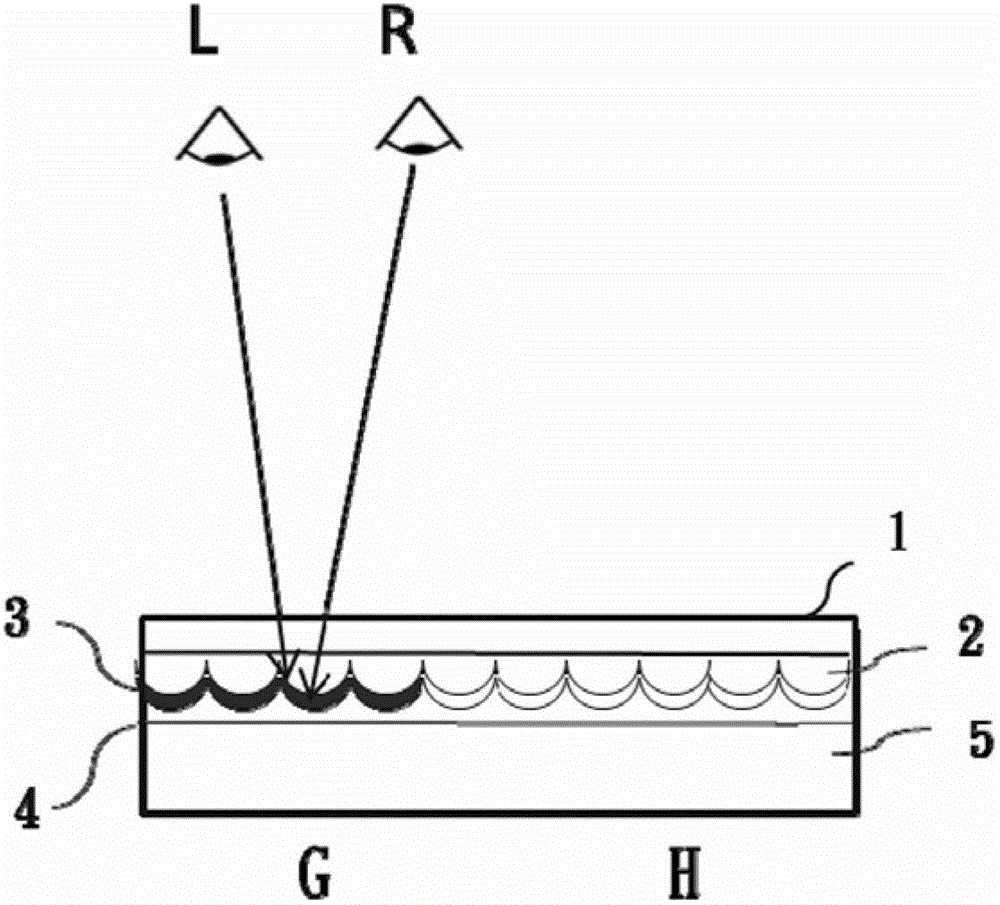

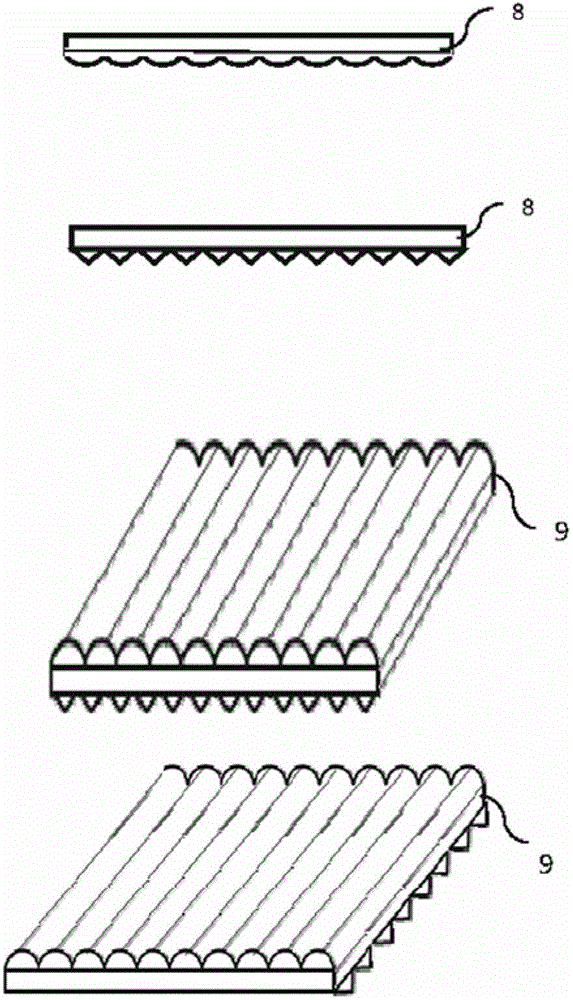

Embodiment 1

[0067] Using a transparent sheet with a hemispherical lens on one side, the Korean company Kolon's MLF LM's hemispherical lens film, its transparent sheet is a 188 micron thick polyethylene terephthalate (PET) optical film, with a heat distortion temperature of 120°C, and contains a 42 micron high hemispherical lens, which is ultraviolet Hardened polymethyl methacrylate hemispherical lens, heat deflection temperature 180°C. 120 centimeters long and 80 centimeters wide, it has a hemispherical lens density of about 70,000 lenses per square inch. The industrial-grade digital inkjet printing machine exposed to ultraviolet rays prints the printing layer 3 with precise patterns on the surface of the hemispherical lens. The pattern precision is 600 dots per inch (equivalent to 360,000 dots per square inch), thus forming a three-dimensional Printed transparent sheet. The printing resolution of this example is 5 times of the lens density, and the printed transparent sheet obtained h...

Embodiment 2

[0069] Utilizes 80 micron thick triacetate cellulose optical film, heat distortion temperature 80°C, contains 20 micron high hemispherical lens, which is UV hardened hemispherical lens, which is The heat distortion temperature of several resins (Epoxy) is 250°C. 120 centimeters long and 80 centimeters wide, it has a hemispherical lens density of about 50,000 lenses per square inch. The industrial-grade digital inkjet printing machine exposed to ultraviolet rays prints the printing layer 3 with precise patterns on the surface of the hemispherical lens. The pattern precision is 800 dots per inch (equivalent to 640,000 dots per square inch), thus forming a three-dimensional Printed transparent sheet. The printing resolution of this example is 13 times of the lens density, and the printed transparent sheet obtained has excellent three-dimensional printing effect and pattern resolution. The printed transparent sheet is combined with the electronic window by gluing. The adhesive ...

Embodiment 3

[0071] Add light-emitting diode light sources such as Figure 6 As shown, the distance between the LED and the transparent sheet is 5mm and it is connected to the rotary switch. The LED adopts the F5 white LED in-line lamp bead of Shanghai Deye Technology Co., Ltd., and is connected to the R13-87 three-way lamp of Shenzhen Yalong Electric Co., Ltd. The rotary switch, or the organic light emitting diode light source, is directly connected to the transparent sheet and connected to the rotary switch, thereby obtaining a three-dimensional electronic window with lighting function, and the transparency of the electronic window and the LED switch can be controlled by the switch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com