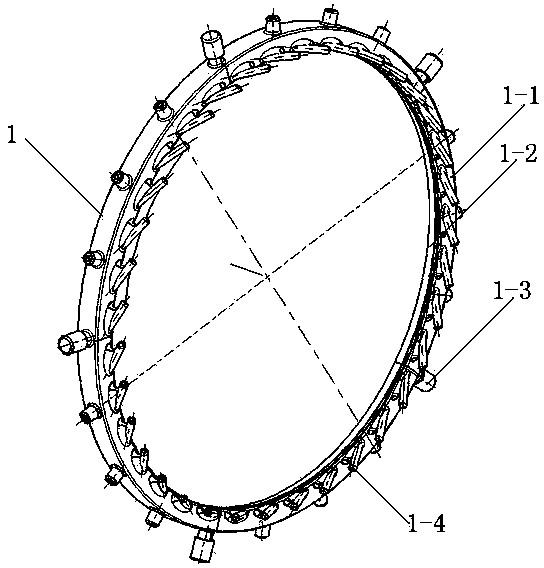

Preparation method for guide vane inner ring split combined type hollow ceramic mold core

A technology of hollow ceramics and ceramic cores, which is applied in cores, casting molding equipment, casting molds, etc., can solve the problems of expensive molds, ceramic cores that cannot be burned through, and easy core breakage, so as to improve the product qualification rate, The effect of reducing casting deformation and reducing manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

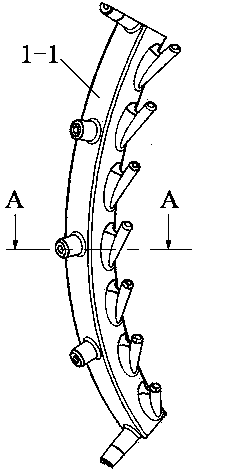

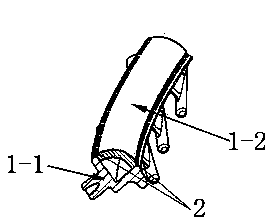

Image

Examples

Embodiment 1

[0037] (1) Prepare raw materials: SiO with a particle size of 220 meshes accounting for 33wt.% of the total weight of raw materials 2 Powder, 21wt.% SiO with a particle size of 300 mesh 2 Powder, 35 wt.% ZrO with a particle size of 300 mesh 2 Mix the powder and 11 wt.% binder, heat to 130°C to form a slurry, stir for 6 hours, then pour the slurry into the barrel of the ceramic core injection machine, and stir for later use;

[0038](2) Pressing the core: Heat the pot mold of the ceramic core to 45°C, control the clamping pressure to 6Mpa, and the grouting pressure to 3Mpa, inject the slurry into the pot mold of the ceramic core, and control the grouting time to 20 second, then keep the pressure for 20 seconds, open the mold, and obtain the basin portion of the ceramic core;

[0039] Replace the mold with a ceramic core back mold, repeat heating, grouting, and pressure holding to obtain the back of the ceramic core;

[0040] Put the basin and the back on the correction mold,...

Embodiment 2

[0047] (1) Prepare raw materials: SiO with a particle size of 220 meshes accounting for 30wt.% of the total weight of raw materials 2 Powder, 18wt.% SiO with a particle size of 300 mesh 2 Powder, 35 wt.% ZrO with a particle size of 300 mesh 2 Mix the powder and 17 wt.% binder, heat to 130°C to form a slurry, stir for 6 hours, then pour the slurry into the barrel of the ceramic core injection machine, and stir for later use;

[0048] (2) Pressing the core: heat the pot mold of the ceramic core to 40°C with a fixture, control the clamping pressure to 6Mpa, and the grouting pressure to 3Mpa, inject the slurry into the pot mold of the ceramic core, and control the grouting time For 20 seconds, then hold the pressure for 20 seconds, open the mold, and obtain the basin portion of the ceramic core;

[0049] Replace the mold with a ceramic core back mold, repeat heating, grouting, and pressure holding to obtain the back of the ceramic core;

[0050] Put the basin and the back on th...

Embodiment 3

[0056] (1) Prepare raw materials: SiO with a particle size of 220 meshes accounting for 37wt.% of the total weight of raw materials 2 Powder, 23wt.% SiO with a particle size of 300 mesh 2 Powder, 32 wt.% ZrO with a particle size of 300 mesh 2 Mix the powder and 8 wt.% binder, heat to 130°C to form a slurry, stir for 6 hours, then pour the slurry into the barrel of the ceramic core injection machine, and stir for later use;

[0057] (2) Compression core: Heat the pot mold of the ceramic core to 50°C with a fixture, control the clamping pressure to 6Mpa, and the grouting pressure to 3Mpa, inject the slurry into the pot mold of the ceramic core, and control the grouting time For 20 seconds, then hold the pressure for 20 seconds, open the mold, and obtain the basin portion of the ceramic core;

[0058] Replace the mold with a ceramic core back mold, repeat heating, grouting, and pressure holding to obtain the back of the ceramic core;

[0059] Put the basin and the back on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com